An observation device for a reaction kettle

A technology of observation device and reaction kettle, applied in chemical/physical/physical-chemical process, chemical instrument and method, chemical/physical process, etc., can solve problems such as difficult reaction conditions, whether unfavorable reactions are completed, etc., and achieve fast and convenient operation and use , to ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

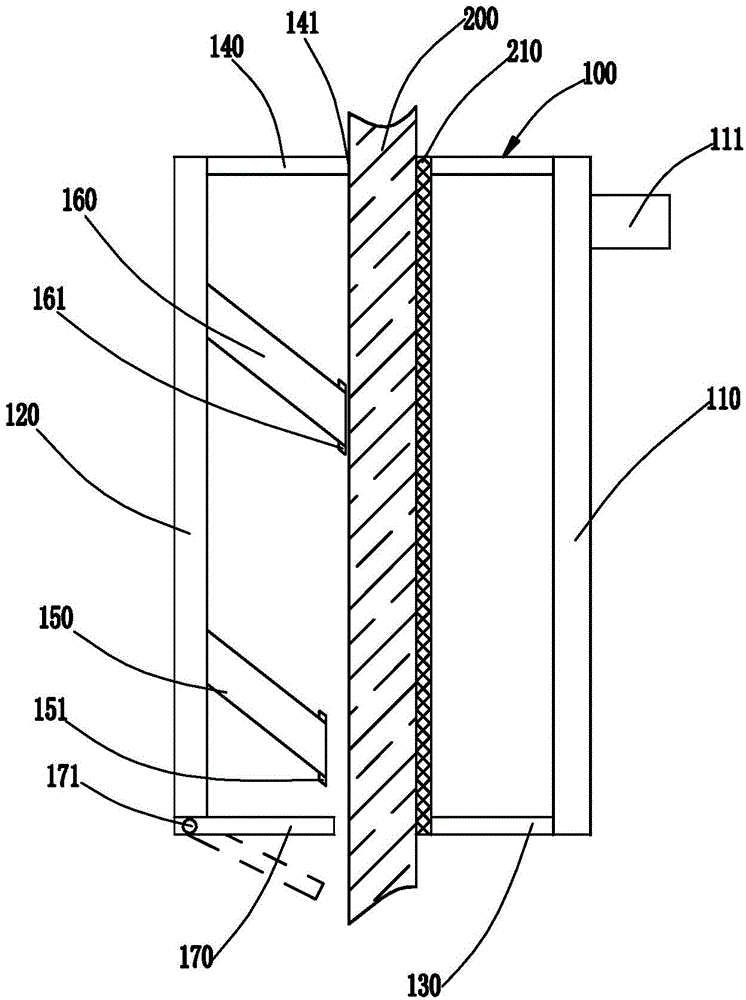

[0022] Such as figure 1 As shown, this embodiment discloses an observation device for a reactor, including a frame 100, composed of a first vertical plate 110, a second vertical plate 120, a third horizontal plate 130, and a fourth horizontal plate 140. In the middle of the plate 140 is a through hole 141, through which the observation glass 200 of the reactor passes through, and abuts against the end of the third horizontal plate 130 away from the first vertical plate 110, on the inner side of the second vertical plate 120, towards One side of the above-mentioned viewing glass is provided with a first scraper 150 and a second scraper 160 in an inclined manner from bottom to top, the end of the first scraper is connected with a first knife holder, and the end of the second scraper is connected with a second scraper Holder, the length of the first scraper is preferably shorter than the length of the second scraper, and the distance between the first scraper and the observation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com