A kind of pcr plate injection molding method

A technology of injection molding and plate shape, which is applied in the direction of coating, etc., can solve the problems of unfavorable observation of reaction tube sample reaction, rough bottom surface of reaction tube, affecting light penetration effect, etc., to improve product detection effect, product nozzle Less, good light transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

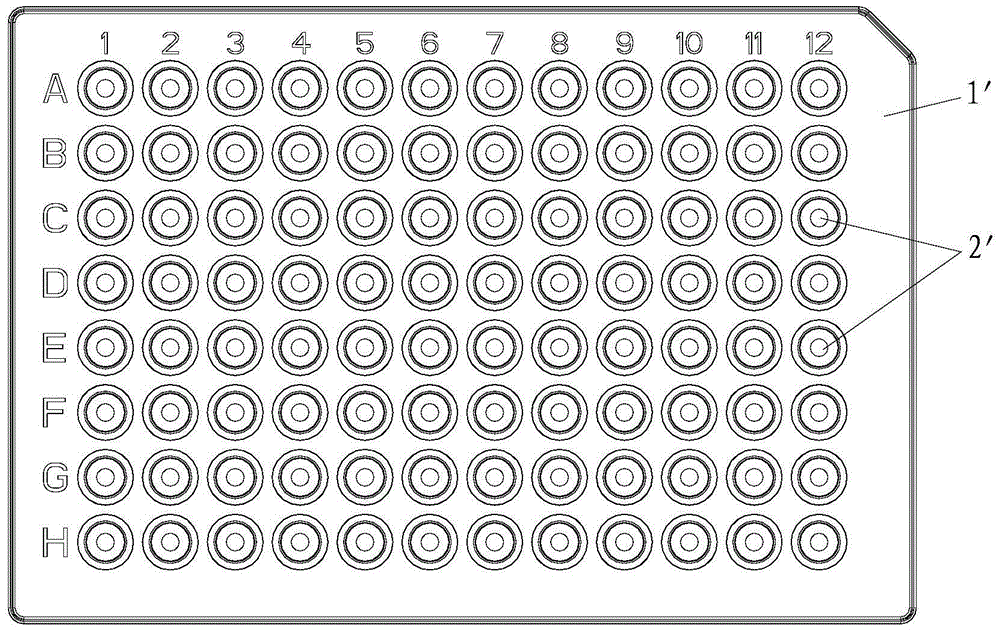

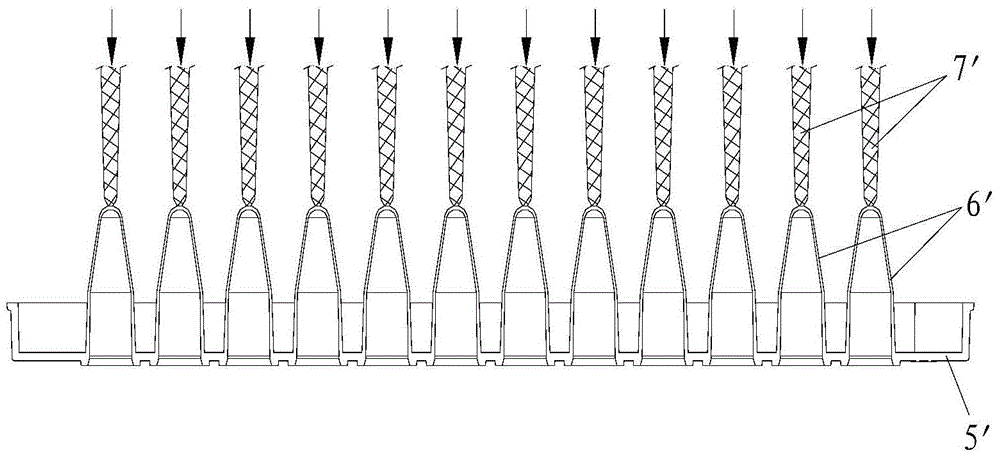

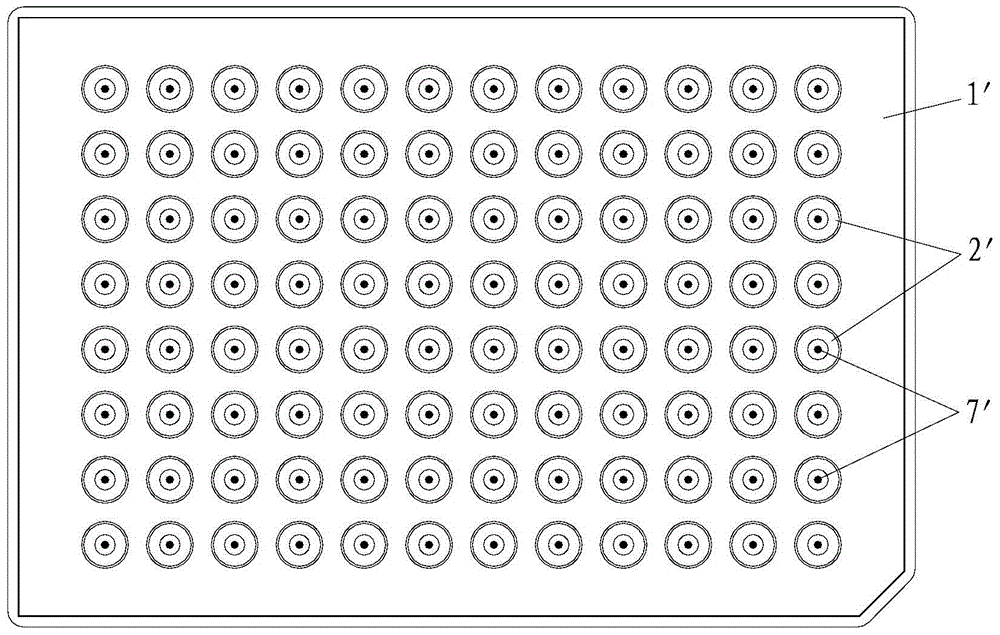

[0027] The present invention will be further described below in conjunction with accompanying drawing and preferred embodiment, see Figure 4-8 As shown, the PCR plate includes a PCR plate frame 1, a plurality of connecting plates 2 and a plurality of reaction tubes 3, and the plurality of reaction tubes 3 are distributed in a matrix, and every 4 adjacent reaction tubes 3 form a group, and in each group The four reaction tubes 3 are connected by a connecting plate 2, the PCR plate frame 1 is made of PC material, and the connecting plate 2 and reaction tubes 3 are made of PP material. Of course, all the reaction tubes 3 can also be connected by only one connecting plate 2 .

[0028] The injection molding method of above-mentioned PCR plate, comprises the following steps:

[0029] 1. Prepare the PCR plate frame 1 so that the PCR plate frame 1 forms a plurality of holes corresponding to the reaction tubes 3 .

[0030] Two, form the PCR plate cavity in the forming mold 4, make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com