Vibrating screen

A technology of vibrating screen and sieve plate, applied in the direction of filter screen, solid separation, grille, etc., to achieve the effect of high mechanical strength, high mechanical strength and uniform process size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

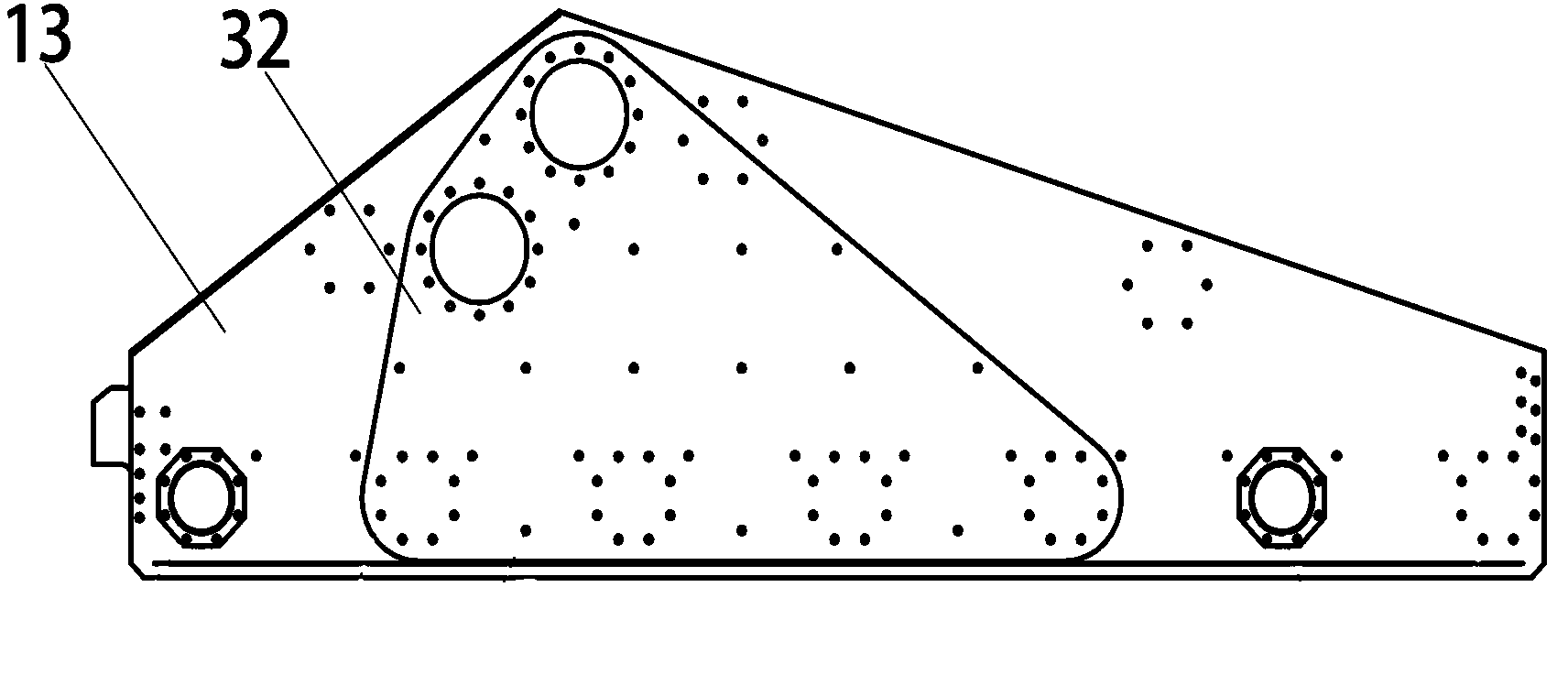

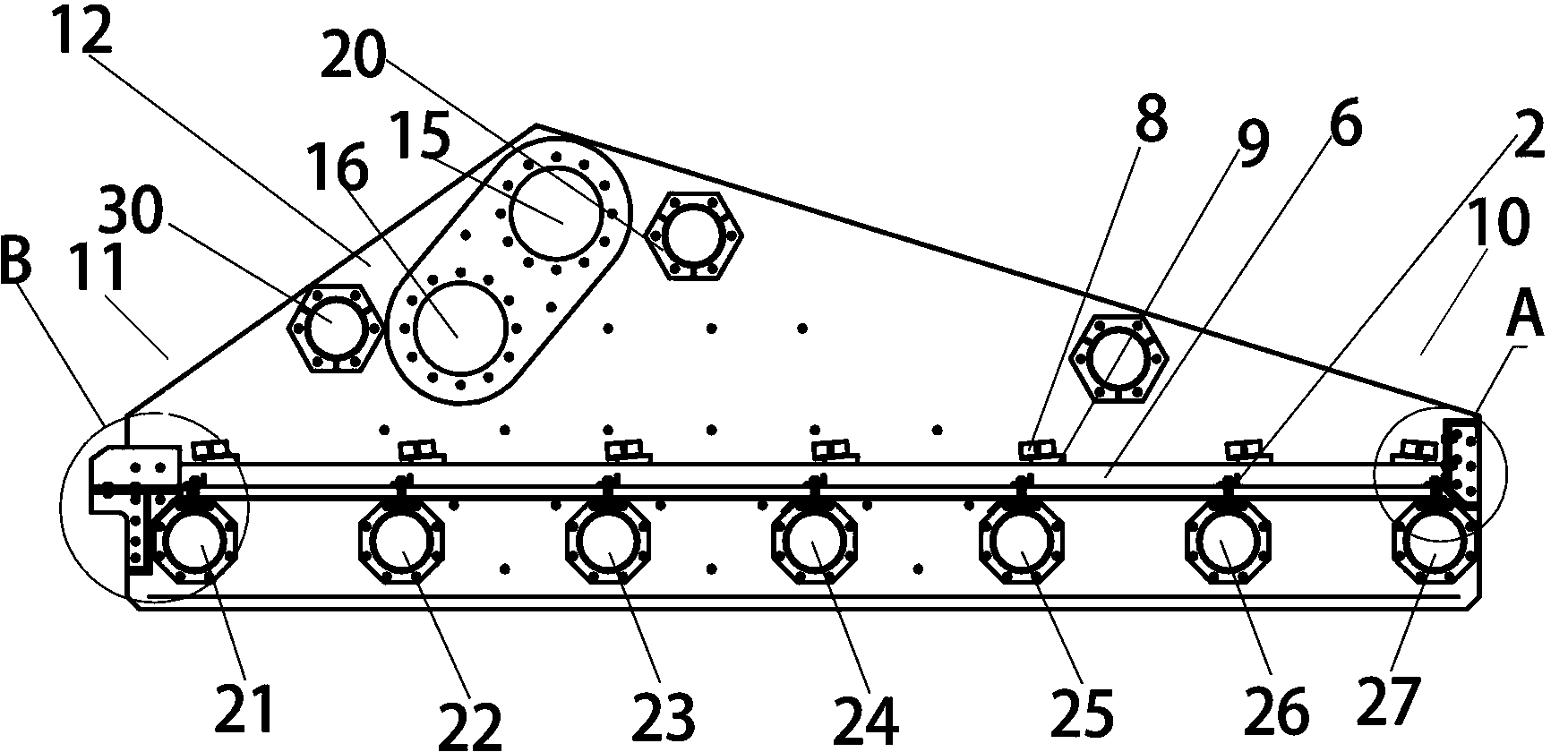

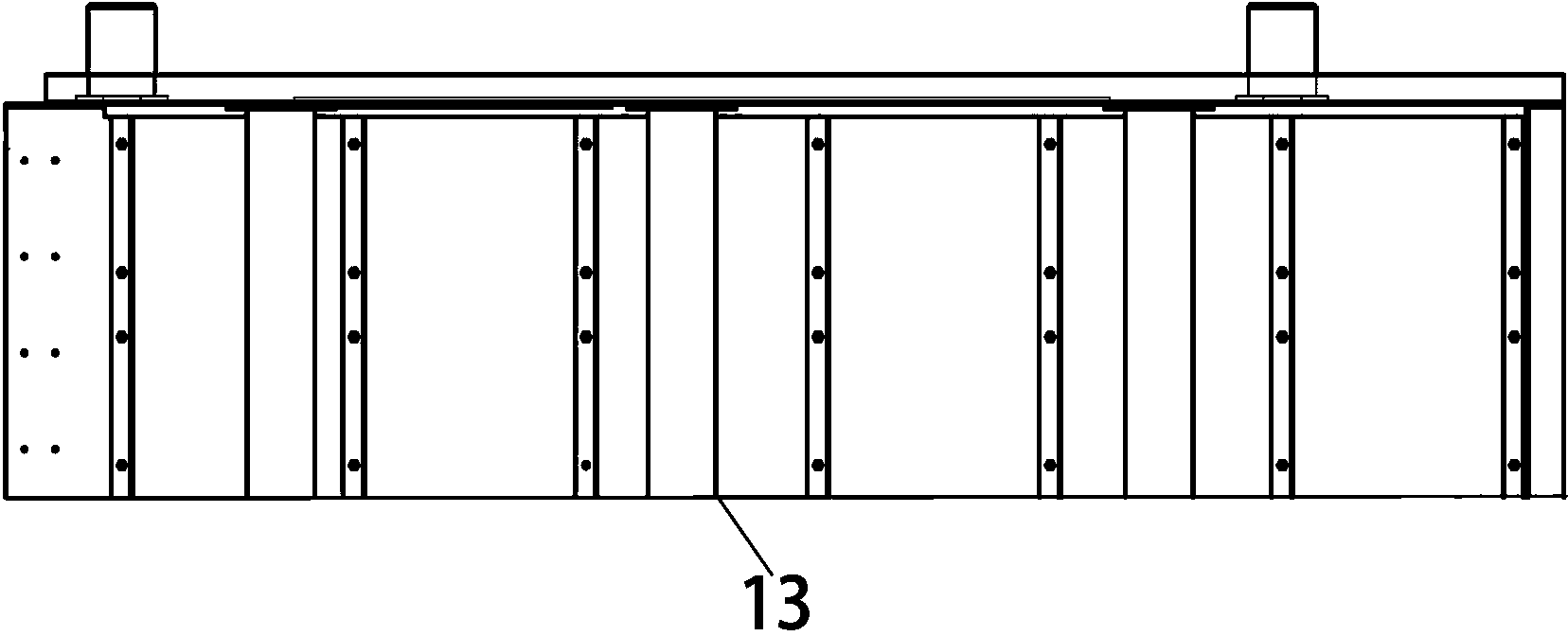

[0039] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0040] like Figure 1-3 As shown, an embodiment of the vibrating screen according to the present invention includes a beam installed on a shock-absorbing base, a first side plate 12 and a second side plate 13 installed at both ends of the beam, a sieve plate 1 placed on the top of the beam, and a motor , the first side plate 12 and the second side plate 13 are parallel to each other. There are multiple beams connected between the first panel 12 and the second side panel 13, including a first beam 21, a second beam 22, a third beam 23, a fourth beam 24, a fifth beam 25, and a sixth beam 26. , the seventh beam 27 . The cross beams are installed between the first side plate 12 and the second side plate 13 parallel to each other. A sieve plate 1 is arranged on the upper part of the plurality of beams. The first crossbeam 21, the second cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com