Production method of mixer hopper with cutter

A manufacturing method and mixer technology, which can be used in the direction of unpacking objects, selling raw material supply devices, packaging, etc., can solve problems such as affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

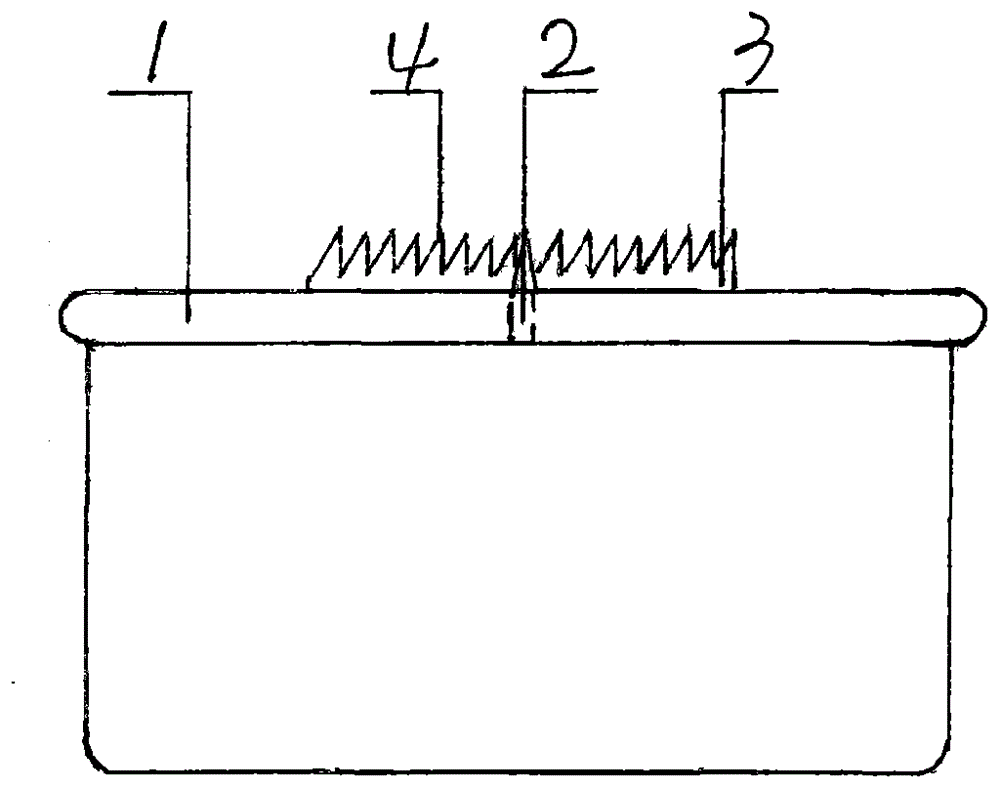

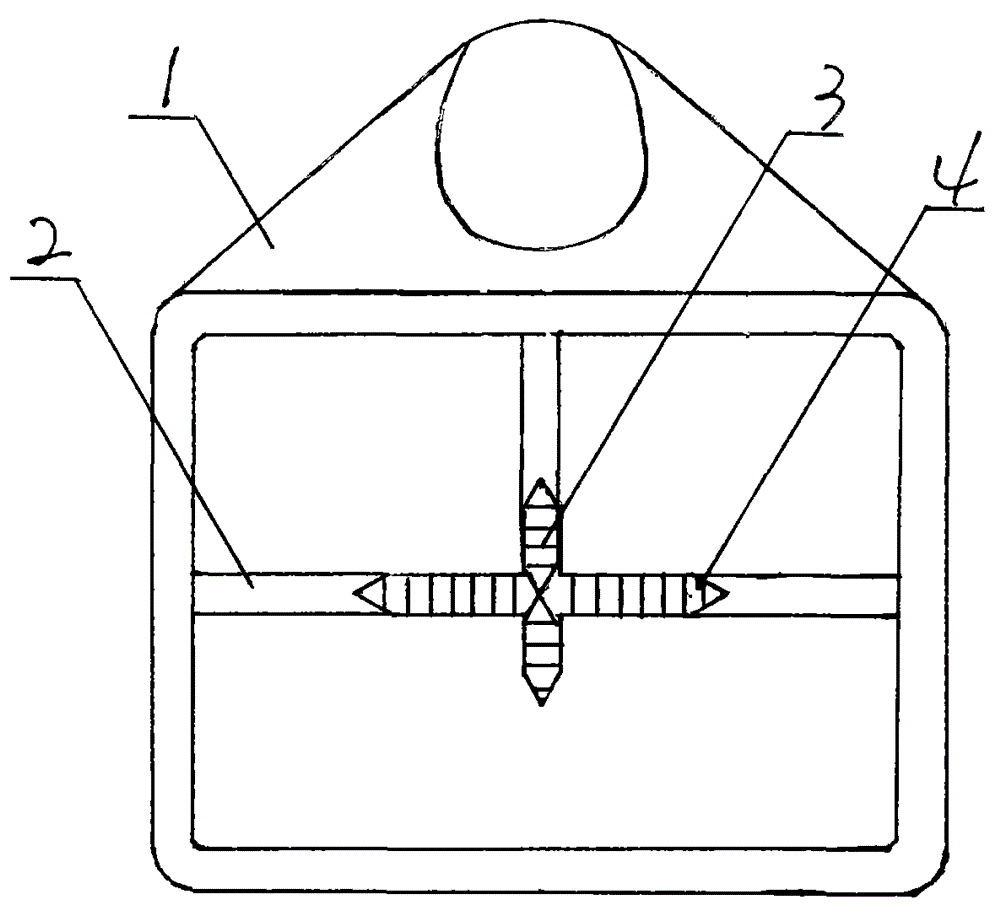

[0008] Such as figure 1 , 2 As shown, a method for manufacturing a mixer hopper with a splitting knife is provided, which can use the gravity impact of cement to complete the splitting operation. The splitting knife of the hopper 1 is installed on the hopper, and the splitting knife is composed of a knife holder 2, a blade 3, and saw teeth 4 composition. Knife rest 2 is made of steel, and the shape of knife rest 2 is cross-shaped. The upper mouth of the hopper 1 is on the same plane. Be welded with blade 3 on knife rest 2, the shape of blade 3 is cross, blade 3 and knife rest 2 spot weldings are connected as a whole, the blade 3 of cutting knife is upward, and blade 3 is higher than the top plane of hopper 1. There are serrations 4 on the blade 3, and the tip of the serrations 4 is a sharp cone, so as to puncture the cement bag. The inclination direction of the sawtooth 4 on the same blade 3 is consistent, so that the empty bag of cement is taken down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com