A connection structure between a prestressed steel cable or a steel strand and a pole end

A prestressed steel cable and connection structure technology, which is applied in the field of supporting fish-belly beams or string beams, and strut end structures, can solve the problems of shortening the service life of steel strands and prone to friction, so as to prolong the service life and reduce construction costs. Risk factor, effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

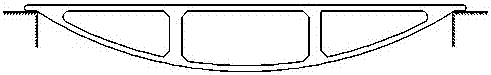

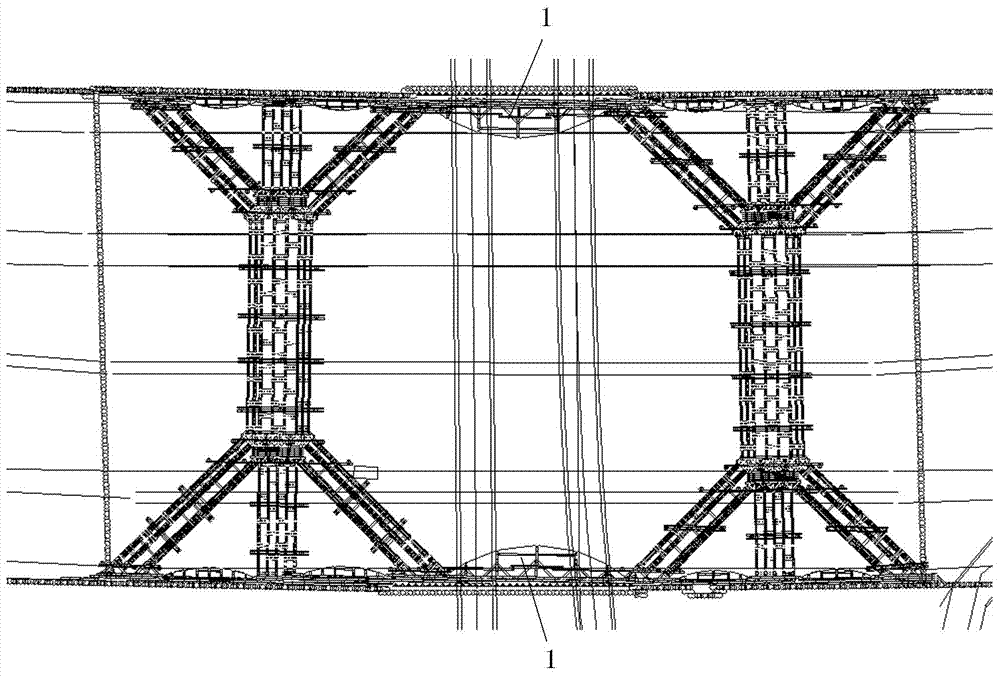

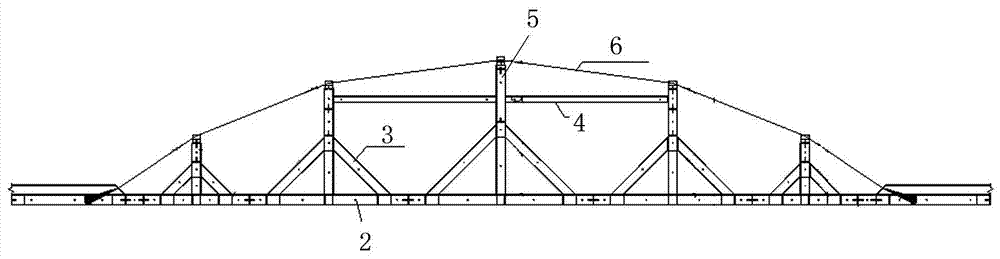

[0015] Taking the fish-belly beam with a span of 37m in a foundation pit as an example, the layout of the fish-belly beam is as follows: image 3 As shown, in the figure 2 is the steel purlin, 3 is the steel outer support, 4 is the steel tie rod, 5 is the support rod, and 6 is the steel strand. Figure 4 It is a structural diagram of a pole end in the prior art, the pole end includes an upper plate 8, a middle plate 9 and a lower plate 10, the upper, middle, and lower plates are welded to the anchor plate 14, and the anchor plate 14 is connected by bolts To the head plate 15 of the strut, the middle reinforcement plate 18 and the facing plate 19 are also connected between the upper, middle and lower plates, so that the steel strand 6 will directly connect with the facing plate 19 of the supporting strut 5 In the process of prestressing, the outer plastic layer of the steel strand is easily damaged by wear and tear, which affects its service life. According to the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com