A method for controlling gas drainage in goaf

A technology of gas extraction and control method, which is applied in gas discharge, mining equipment, earth-moving drilling, etc., can solve the problems of large consumption of pipes, increased cost, complicated installation, etc., and achieves low cost, convenient processing and low economic cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

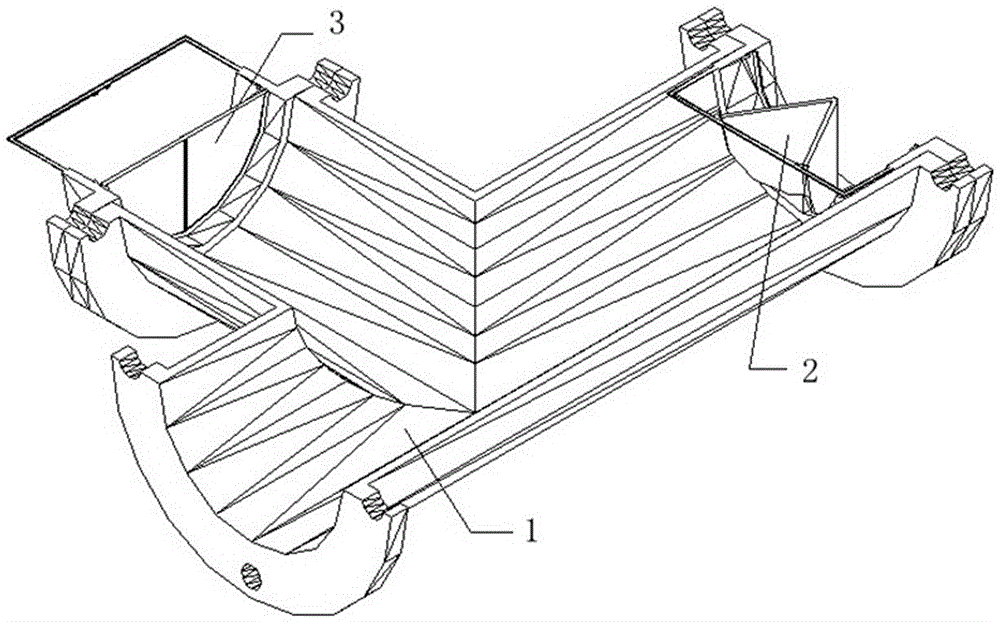

[0017] A gas drainage control device for a goaf, comprising a tee joint 1 connected at one end to the tail of a gas drainage main pipe, a main pipe switch 2 connected to the other end of the tee joint 1 opposite to the gas drainage pipe, and The third end of 1 is connected with branch switch 3;

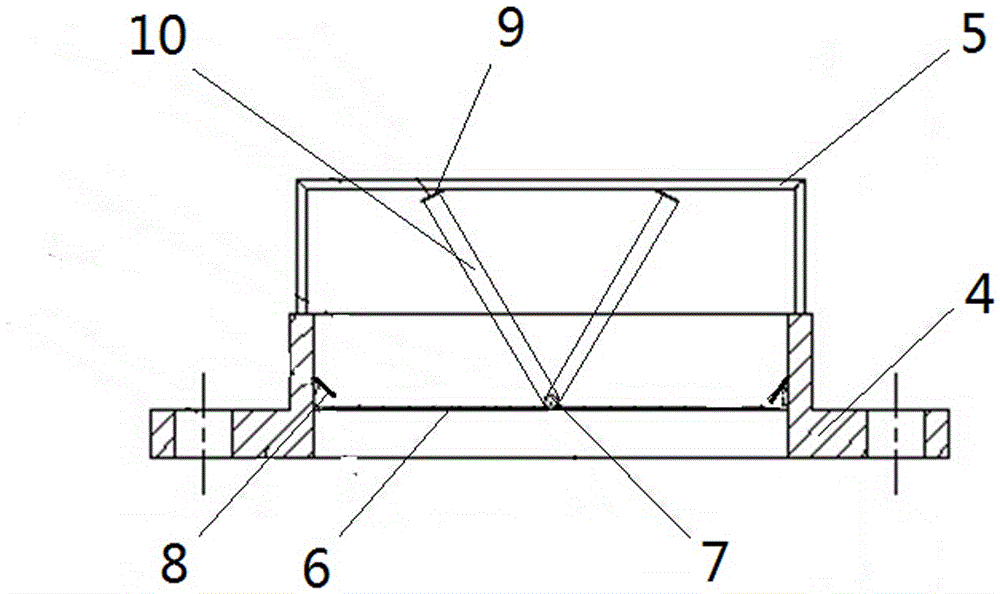

[0018] The dry pipe switch 2 includes a flange-shaped housing 4, an inverted U-shaped strut 5 is fixed on the protruding end of the housing 4, a rubber ring 6 is fixed on the cylindrical surface inside the housing 4, and the housing above the rubber ring 6 4. The inner side is fixed with a rotating shaft 7 and two non-return springs 8 with symmetrical positions. 8 and the semicircular rotating fan 10 that cooperates with the limit shrapnel 9;

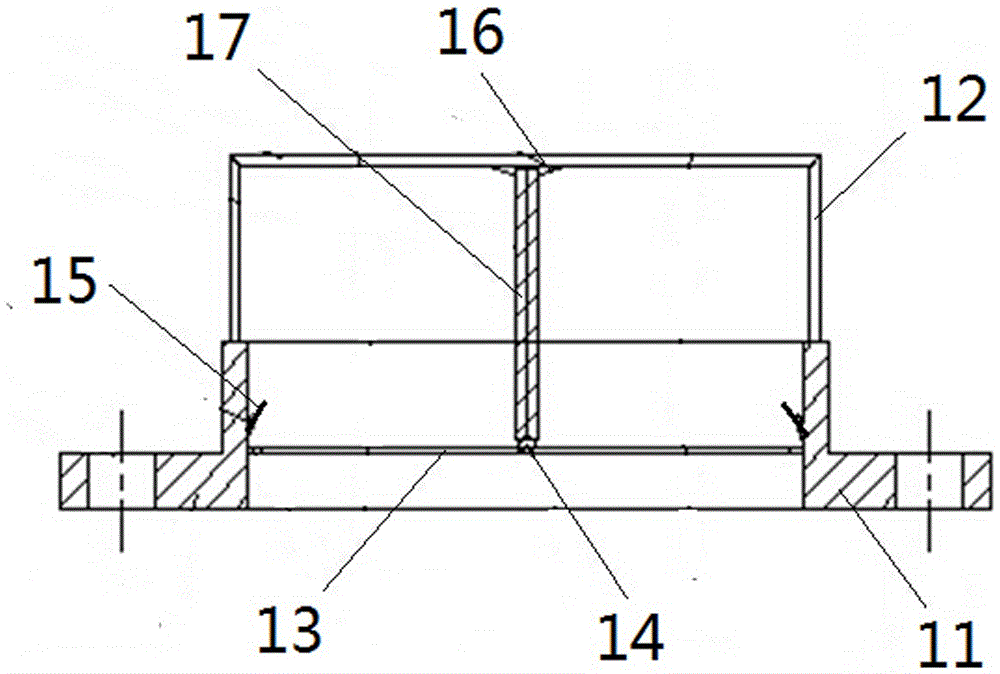

[0019] The branch pipe switch 3 includes a flange-shaped housing I11, an inverted U-shaped strut I12 is fixed on the protruding end of the housing I11, a rubber ring I13 is fixed on the cylindrical surface inside the housing I11, and the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com