Novel dewatering system for production of methoxy-1-methylethylacetate

A new technology of propylene glycol methyl ether acetate, which is applied in the separation/purification of carboxylic acid esters, the preparation of carboxylic acid esters, and the preparation of organic compounds, etc., can solve the problems of large energy consumption, reduce energy consumption, and optimize Safety, effect of reducing exhaust pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

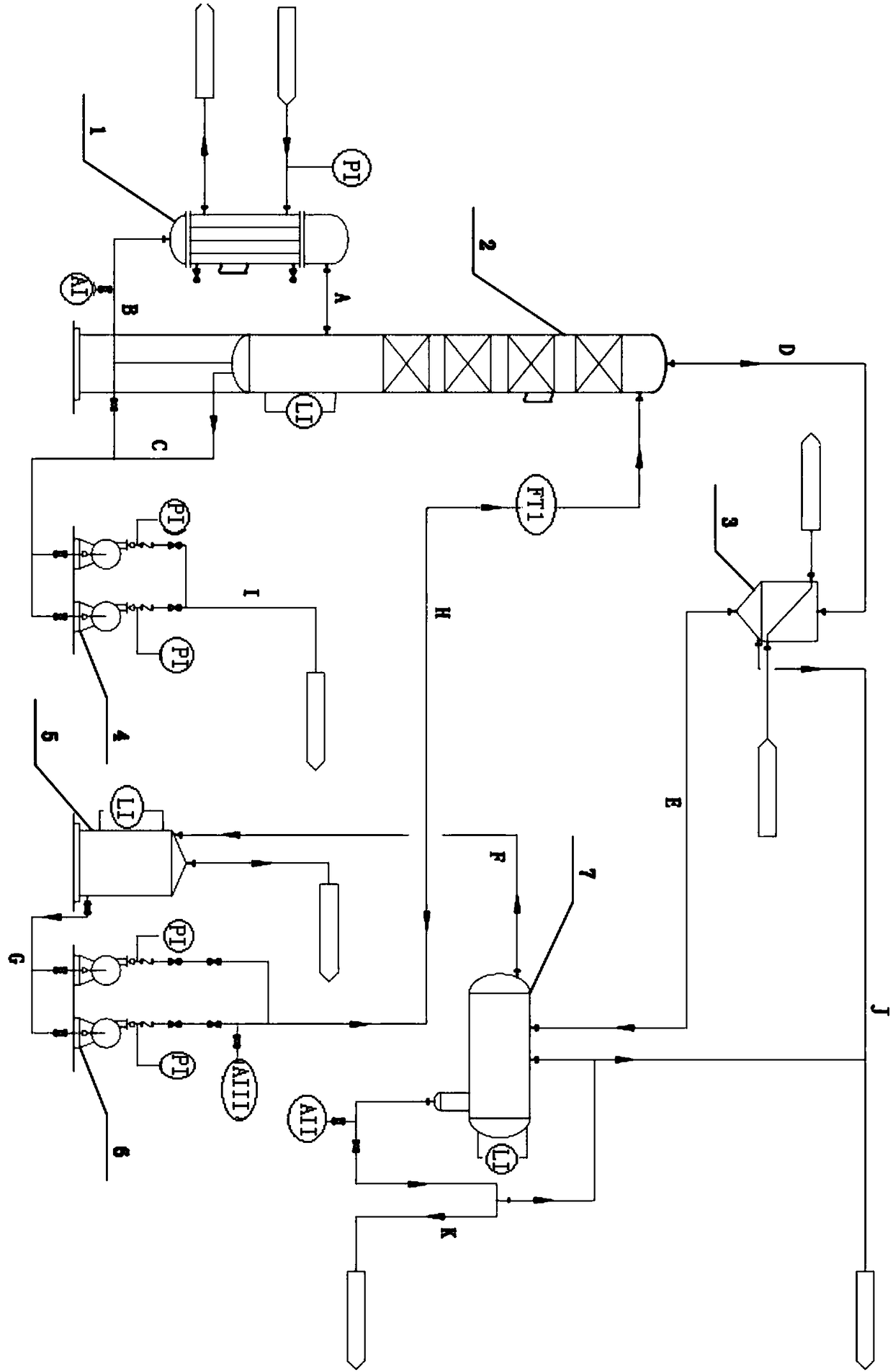

[0062] as attached figure 1 As shown, add 80% ethyl acetate to the reflux tank as a dehydrating agent in advance, and add 80% water to the phase separation tank to prepare for subsequent reflux;

[0063] 1) First, feed the esterification reaction solution into the dehydration refining tower. When the liquid level of the tower kettle reaches 80%, start to heat up. According to the rectification start-up procedure, gradually turn on the reflux pump, and the reflux flow is from 1m 3 / h, gradually increased to 14m 3 / h, until the liquid level in the reflux tank and the phase separation tank is stable, that is, the total reflux operation is completed;

[0064] 2) Start to feed continuously into the dehydration refining tower, and control the feed to 15m according to the production capacity 3 / h, the component mass content distribution of crude ester is probably (propylene glycol methyl ether 21%, acetic acid 24%, propylene glycol methyl ether acetate 50%, water 4%);

[0065] 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com