Purifying and sterilizing method for drinking water

A sterilization method and technology for drinking water, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of complex structure and process of water purification device, the total number of effluent colonies cannot be reached, and the manufacturing cost is rising, etc. problem, to achieve the effect of simple structure, good sterilization effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

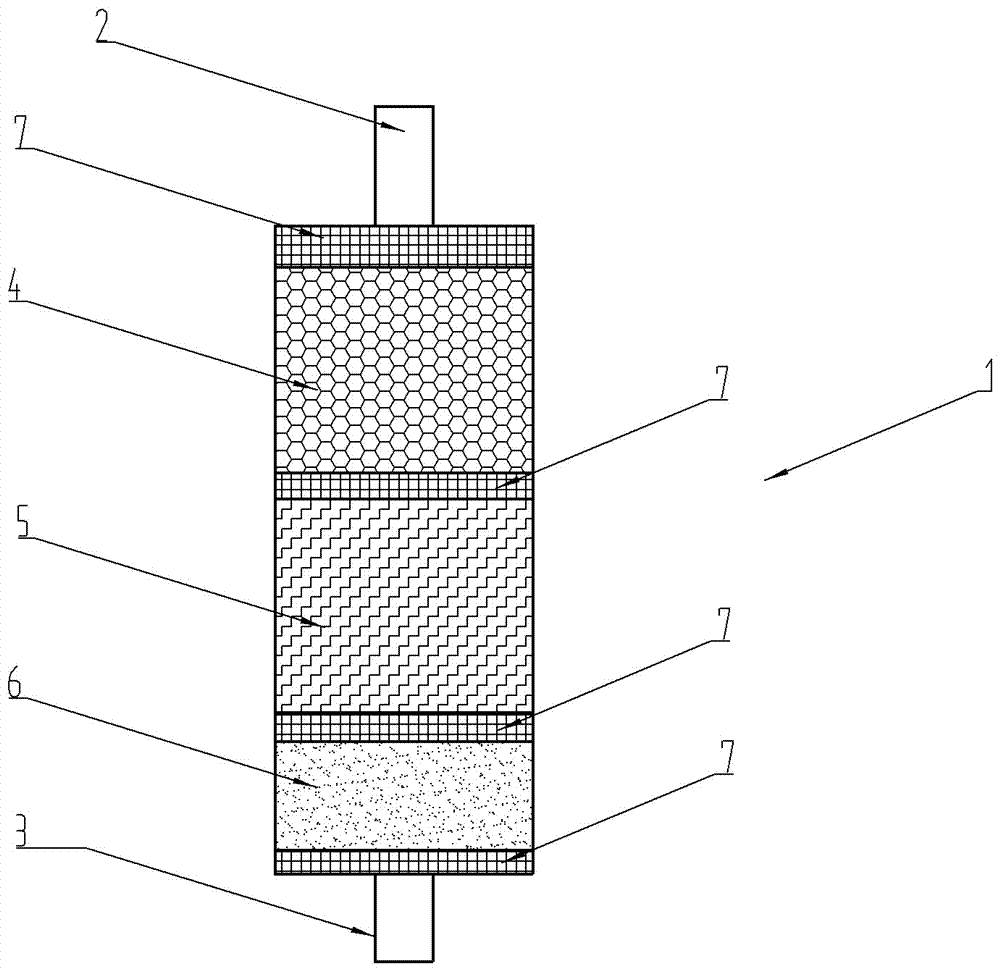

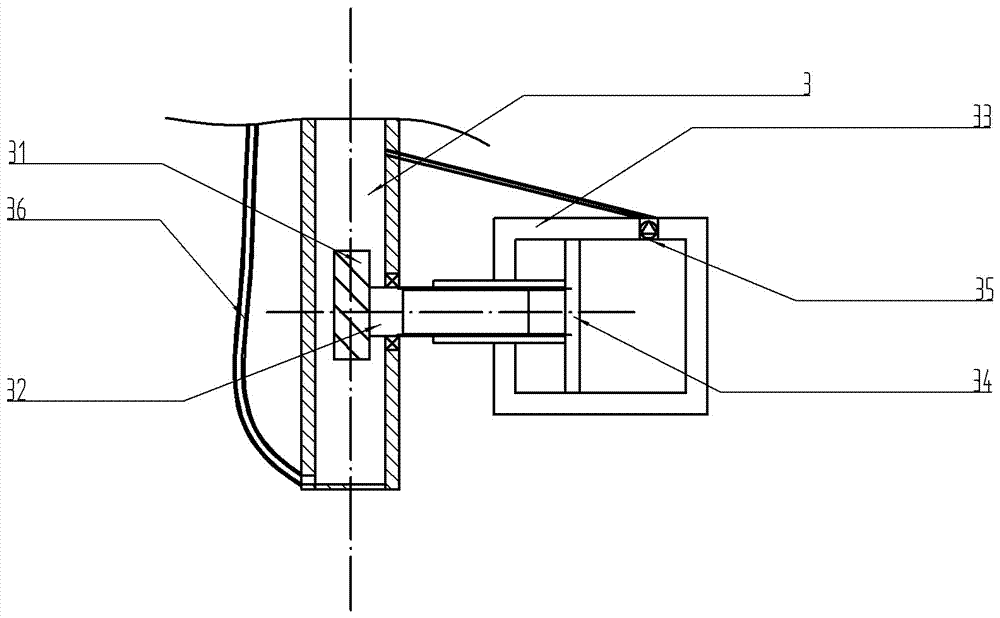

[0030] The reference signs in the accompanying drawings include: pipe body 1, water inlet 2, water outlet 3, impeller 31, rotating shaft 32, air chamber 33, piston 34, valve 35, return pipe 36, sterilization layer 4, water purification layer 5 , heavy metal ion removal layer 6 , dense layer 7 .

[0031] Such as figure 1 As shown, the embodiment of the present invention uses a drinking water filter, including a pipe body 1 and a water inlet 2 and a water outlet 3 arranged at both ends of the pipe body. 3 Sterilization layer 4, water purification layer 5 and heavy metal ion removal layer 6 stacked in sequence.

[0032] The purification and sterilization method for drinking water in the present embodiment includes the following contents:

[0033] Water enters the pipe body and passes through the sterilization layer 4, the water purification layer 5 and the heavy metal ion removal layer 6 from top to bottom, and is discharged from the water outlet 3. The sterilization layer 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com