Combined design method for oscillating tooth sliding vanes and sliding blocks in oscillating tooth drive assembly

A combined design and movable tooth transmission technology, which is applied to gear transmissions, transmissions, components with teeth, etc., can solve problems such as types that are not described in detail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

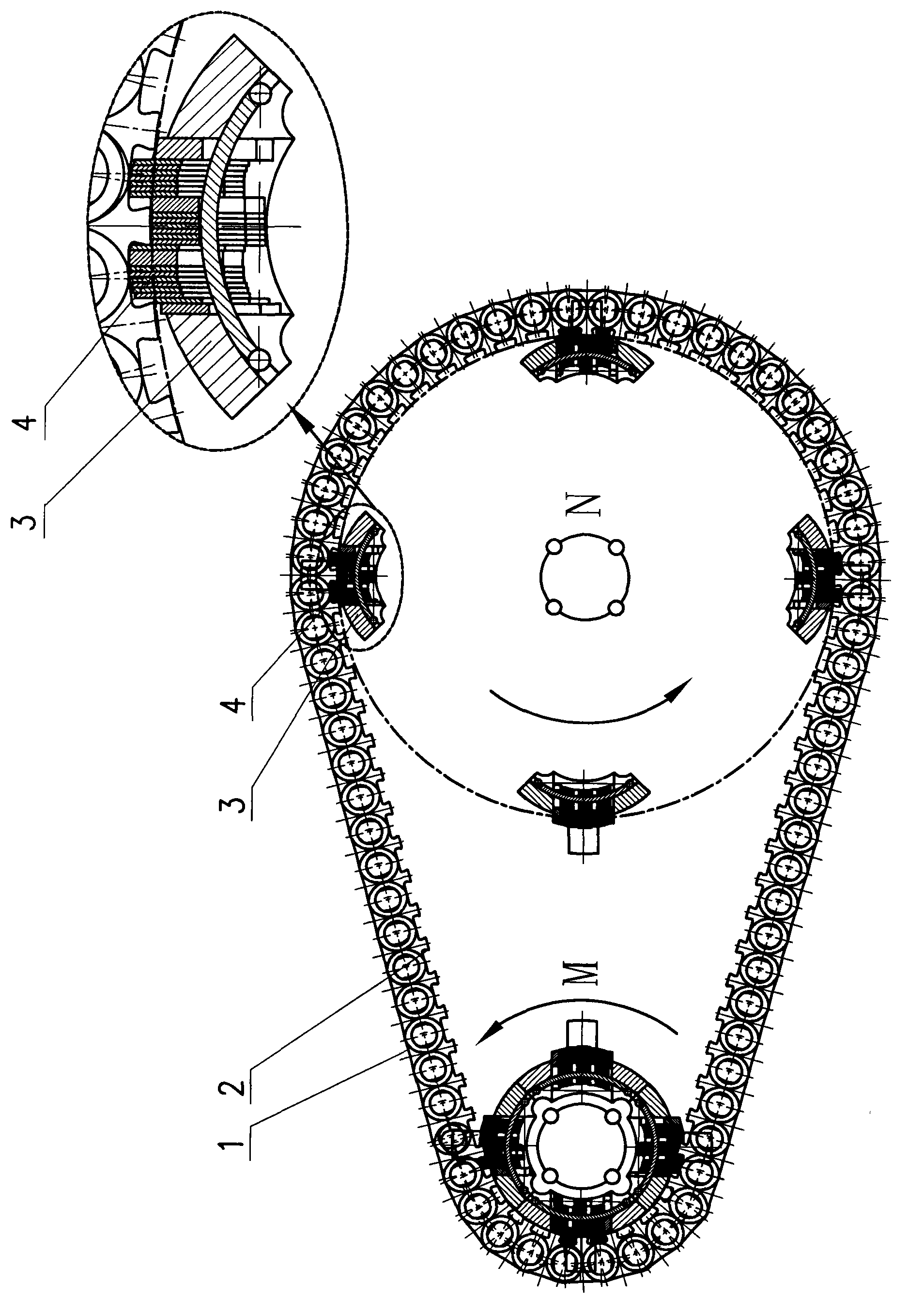

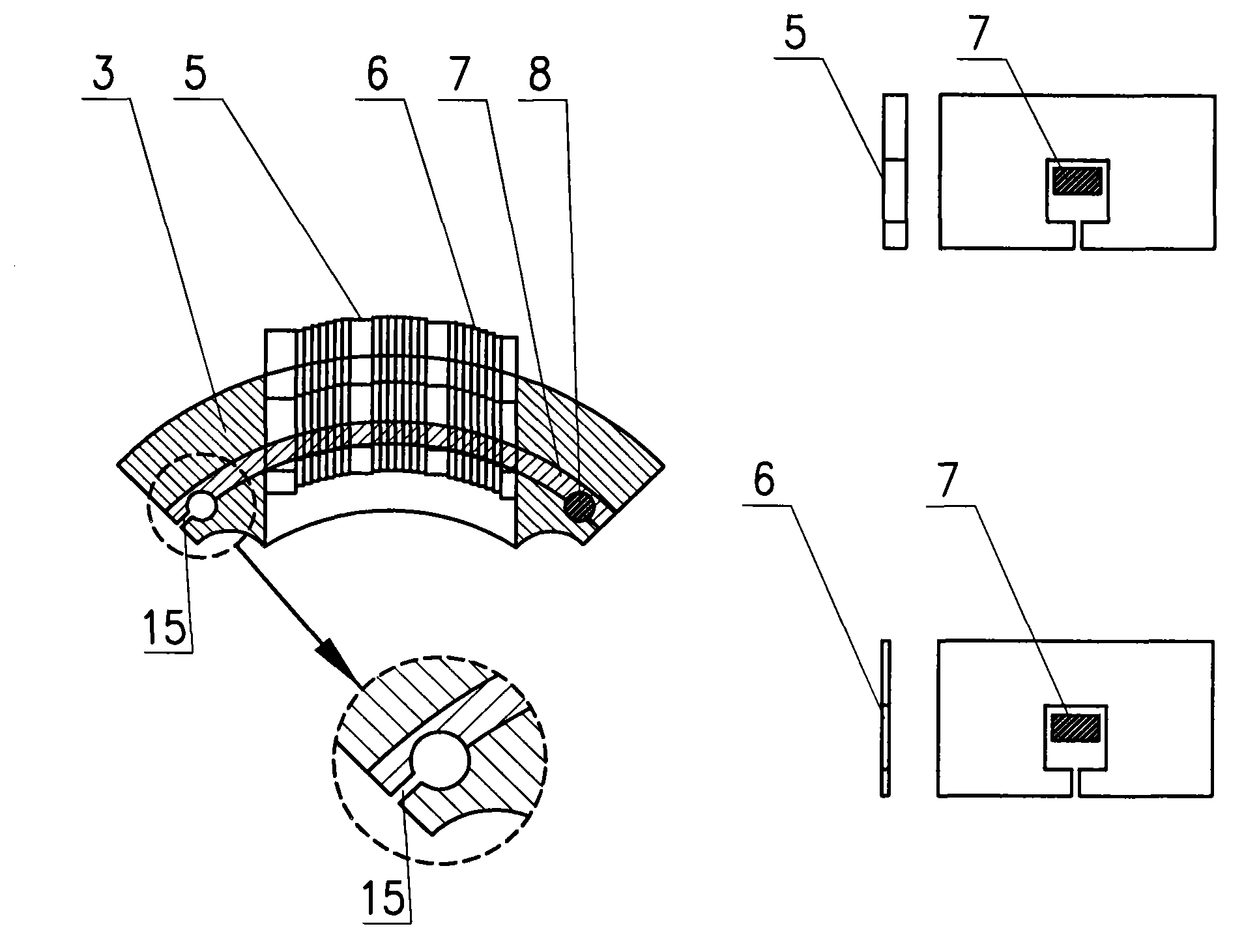

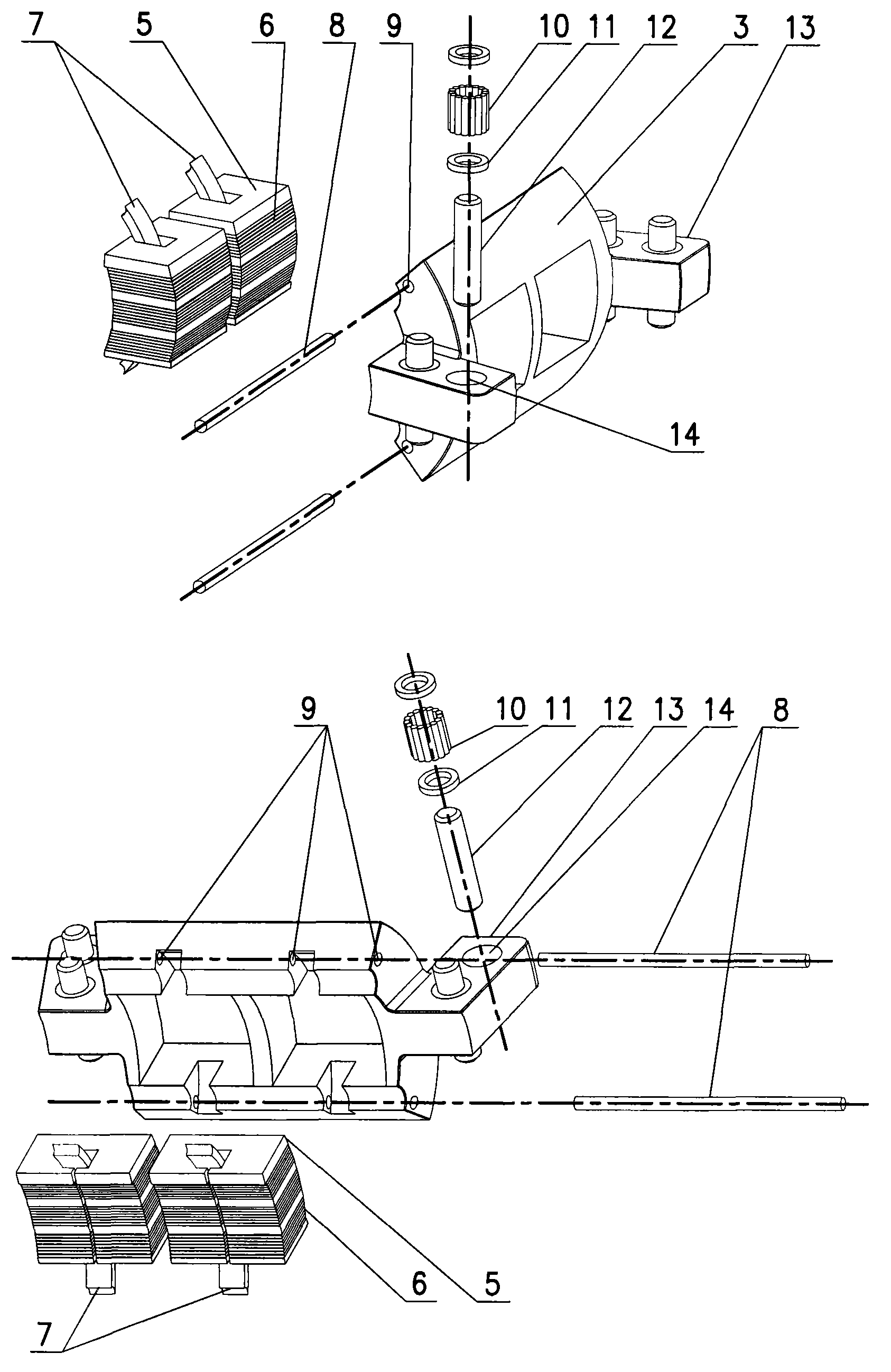

[0019] Examples of the present invention are figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown:

[0020] A slider with a larger thickness is defined as a slider, and a slider with a thinner thickness is defined as a slider. The combination of sliders and sliders is collectively called a slider group.

[0021] The limit and restraint bar of the slider group penetrates through the window of the slider and the slider, and then is inlaid with the groove of the movable tooth unit body to limit the slider and the slider so that it is in the movable tooth unit body. The movement state is constrained, and a certain space for reset and seat movement is reserved. For specific definitions, please refer to its background patent 200580039668.6.

[0022] The specific combination principle of the slider slider is: when the meshing teeth on the transmission belt or the chain press down any slider with a larger thickness in the direction of the load bearing force, in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com