Pilot type safety valve

A pilot-operated safety valve and pilot valve technology, applied in the field of safety valves, can solve problems such as reduced service life, corrosion of pilot valve springs, and increased costs, and achieve the effects of small pressure loss, extended service life, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

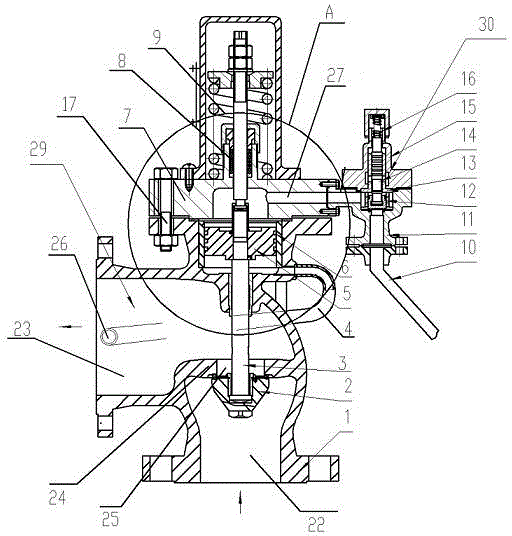

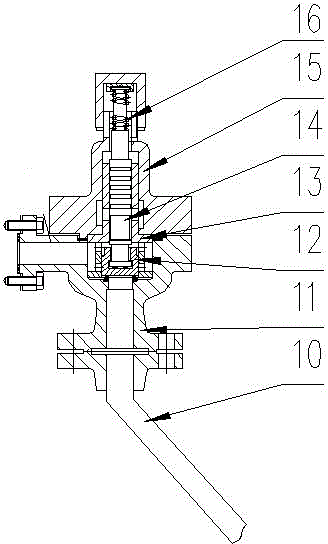

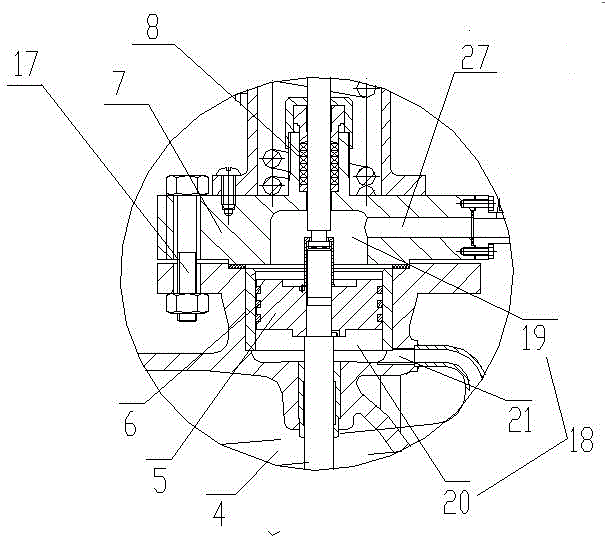

[0014] As shown in the figure, a pilot-operated safety valve includes a main valve 29 and a pilot valve 30, wherein the main valve includes a main valve body 1, a main valve disc 2, a main valve stem 3, and a main valve cover 7 , the main valve spring 9, the piston 5, the piston ring 6, the packing 8 and the conduit 4, the pilot valve includes the pilot valve pressure pipe 10, the pilot valve body 11, the pilot valve disc 12, the pilot valve stem 14, the pilot valve Valve bonnet 15, pilot valve spring 16 and guide sleeve 13; The main valve bonnet 7 is fixed on the top of the main valve body 1 by bolts 17, and the main valve bonnet 7 is provided with a main valve piston cavity 18, so The main valve stem 3 runs through the main valve bonnet 7 and the main valve body 1, and the outer periphery of the main valve stem 3 is provided with a main valve spring 9, a packing 8 and a piston 5 successively from top to bottom, and the main valve stem 3 The bottom end is in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com