Ash removal device and method for combustion disk surface of direct-fired biomass pellet burner

A biomass particle, direct-fired technology, applied in lighting and heating equipment, etc., can solve the problems of no relevant reports, blockage, etc., and achieve the effect of facilitating secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

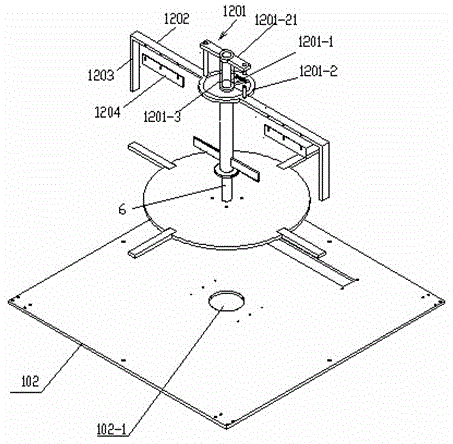

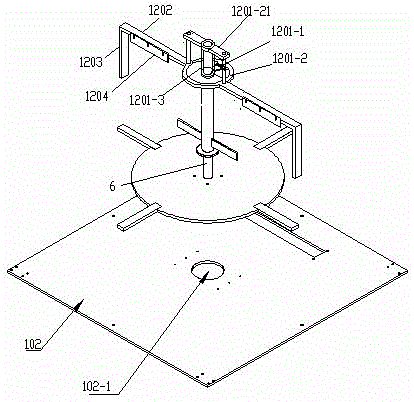

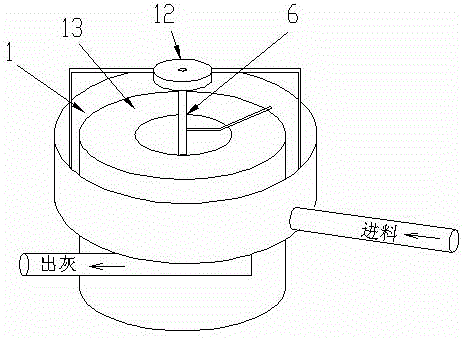

[0026] In order to understand the present invention more clearly, the present invention will be described in detail with reference to the accompanying drawings and embodiments:

[0027] Such as Figure 1-Figure 8 As shown, 1. The combustion disc surface ash removal device of the direct-fired biomass particle burner, the lower part of the combustion disc 13 includes an ash chamber 1, and the ash chamber 1 is provided with a wind chamber 4, and the center of the wind chamber 4 is the main shaft 6, which is characterized by , It also includes a disk surface mechanical ash removal device 12 driven by the spindle 6. The disk surface mechanical ash removal device 12 includes an intermittent transmission mechanism 1201 combined with the spindle 6, a horizontal arm 1202 fixed with the intermittent transmission mechanism, and a horizontal arm 1202 Vertical arms 1203 bent downward at both ends;

[0028] The intermittent transmission mechanism 1201 is composed of an incomplete gear 1201-1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com