Switch contact containing molybdenum alloy coating and preparation method thereof

A switch contact, molybdenum alloy technology, applied in the direction of contacts, electrical switches, electrical components, etc., can solve problems such as low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Plating solution composition: sodium molybdate dihydrate 50g / L, nickel sulfate hexahydrate 20g / L, sodium hypophosphite monohydrate 40g / L, sodium acetate 25g / L, sodium citrate 50g / L, sodium fluoride 2g / L , ammonium sulfate 20g / L, thiourea 0.2g / L, potassium sodium tartrate 30g / L, sodium pyrophosphate 24g / L, potassium iodate 40mg / L, sodium lauryl sulfate 0.5g / L. Ammonia water is added in an appropriate amount to maintain the pH value of the plating solution between 8.5 and 9.5.

[0059] Routing:

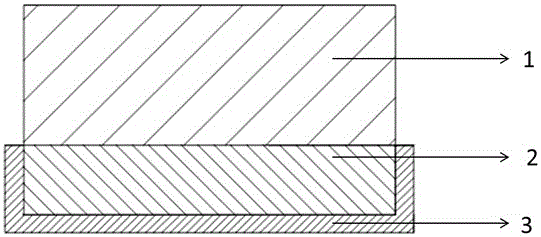

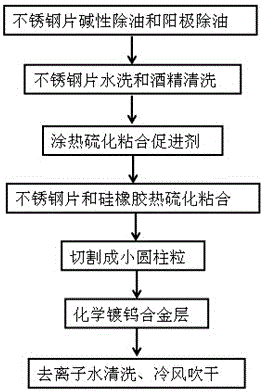

[0060] Such as figure 1 As shown, one side of a 0.1mm thick flat stainless steel sheet (stainless steel type 304) is mechanically roughened (sand blasted or sanded), then alkaline degreased, cleaned with deionized water, and air-dried , The side of the stainless steel that has been sandblasted and roughened is primed with a rubber-metal adhesive ChemlokCH238, and then the side that has been primed is treated with a compound of ethylene-propylene-diene rubber (EPDM) Thermal vul...

Embodiment 2

[0065] Plating solution composition: sodium molybdate dihydrate 60g / L, nickel sulfate hexahydrate 10g / L, basic nickel carbonate tetrahydrate 10 / L, hydrazine 100 / L, sodium pyrophosphate 15g / L, potassium sodium tartrate 20g / L, Sodium lauryl sulfate 0.5g / L. Ammonia water is added in an appropriate amount to maintain the pH value of the plating solution between 8.5 and 9.5.

[0066] Routing

[0067] Etch one side of a 0.075mm thick flat stainless steel sheet (type 304) with an acidified ferric chloride etching solution to etch out evenly distributed small holes with a diameter of 0.25mm and a depth of 0.03-0.04mm, and the spacing between the small holes is 0.25mm. mm. Then the stainless steel sheet is subjected to alkaline degreasing, cleaned with deionized water, air-dried, and the flat side of the stainless steel is primed with a water-based rubber-metal adhesive Megum? W2535 produced by Rohm and Haas Company of the United States. Coating treatment, and then thermally vulcani...

Embodiment 3

[0071] Using 400-mesh stainless steel plain mesh (stainless steel type 304) to replace the stainless steel sheet in Example 1, using the process and chemical plating solution in Implementation 1, the contacts produced also have lower contact resistance and better contact resistance. Arc ablation resistance performance.

[0072] The 400-mesh stainless steel mesh has very small mesh, and when it is molded with silicone rubber, the silicone rubber will not penetrate the mesh of the stainless steel mesh. If you choose a stainless steel mesh with a small mesh number, such as a stainless steel mesh below 80 mesh, there will be a technical problem that silicone rubber penetrates the stainless steel mesh during molding. Therefore, it is necessary to use a larger mesh stainless steel mesh to prepare the coated switch contacts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com