Photovoltaic power station rainproof combiner box

A photovoltaic power station and combiner box technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of high welding precision, affecting product quality, reducing service life, etc., achieve good water resistance, reduce processing procedures, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

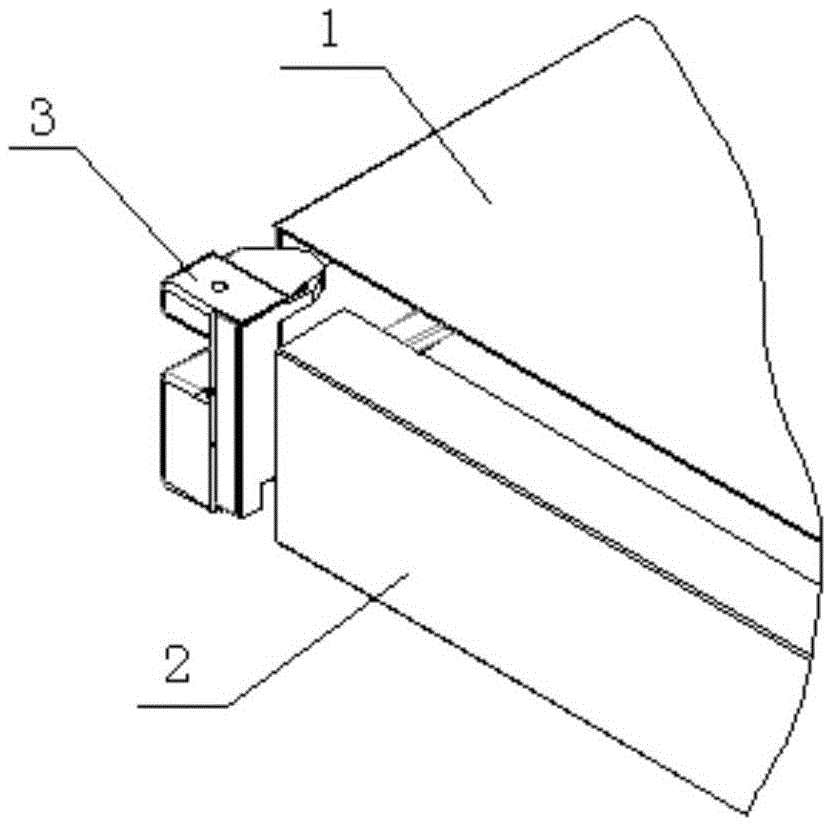

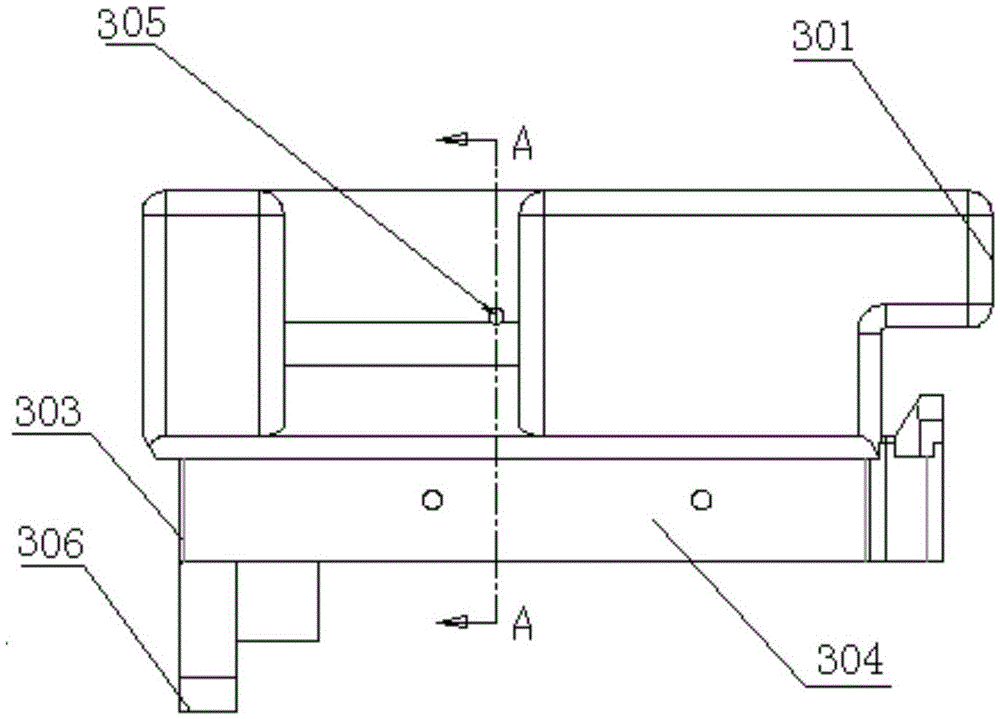

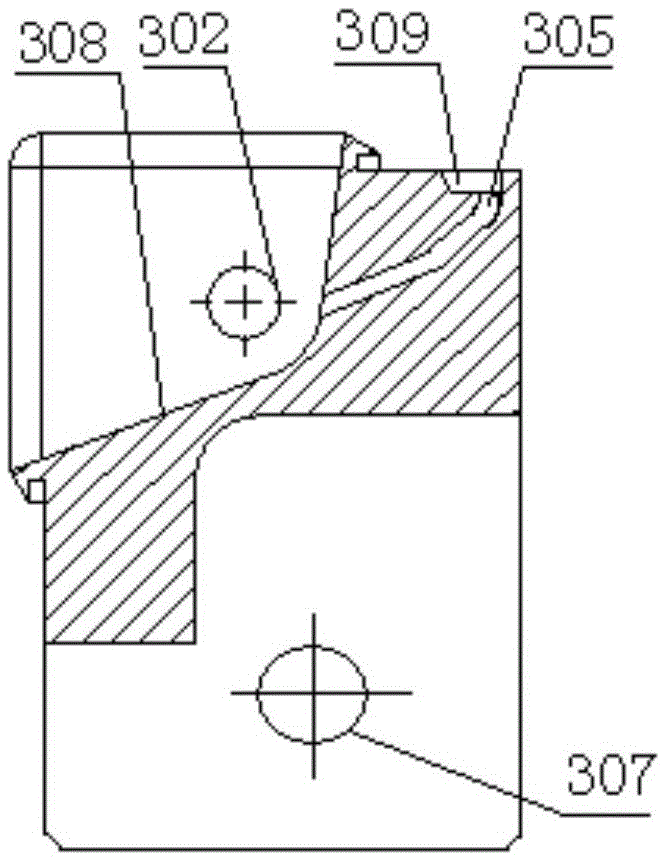

[0018] A photovoltaic power station rainproof combiner box provided in this embodiment includes a box body 1, the box body 1 is in the shape of a cuboid, and the upper and lower ends of the box body 1 are openings, and the openings on the upper end surface and the lower end surface of the box body 1 are respectively provided with The upper sealing plate 2 and the lower sealing plate with the same structure, the four corners of the box body 1 are provided with connecting pieces 3, through which the connecting piece 3 is connected with the upper sealing plate 2 and the lower sealing plate on the upper and lower ends of the box body 1, and the connecting piece 3 A first boss 301 extends from one end, and the end surface of the first boss 301 is flush with one side of the box body 1. The other end of the connector 3 is provided with a box installation hole 302, and the lower end of the connector 3 extends out of the box body. Slot 303, the second boss 306 is also extended from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com