Light source adjusting method and system

A light source adjustment and light source technology, applied in the direction of light source, electric light source, electroluminescent light source, etc., can solve the problems of high cost and long time, and achieve the effect of convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

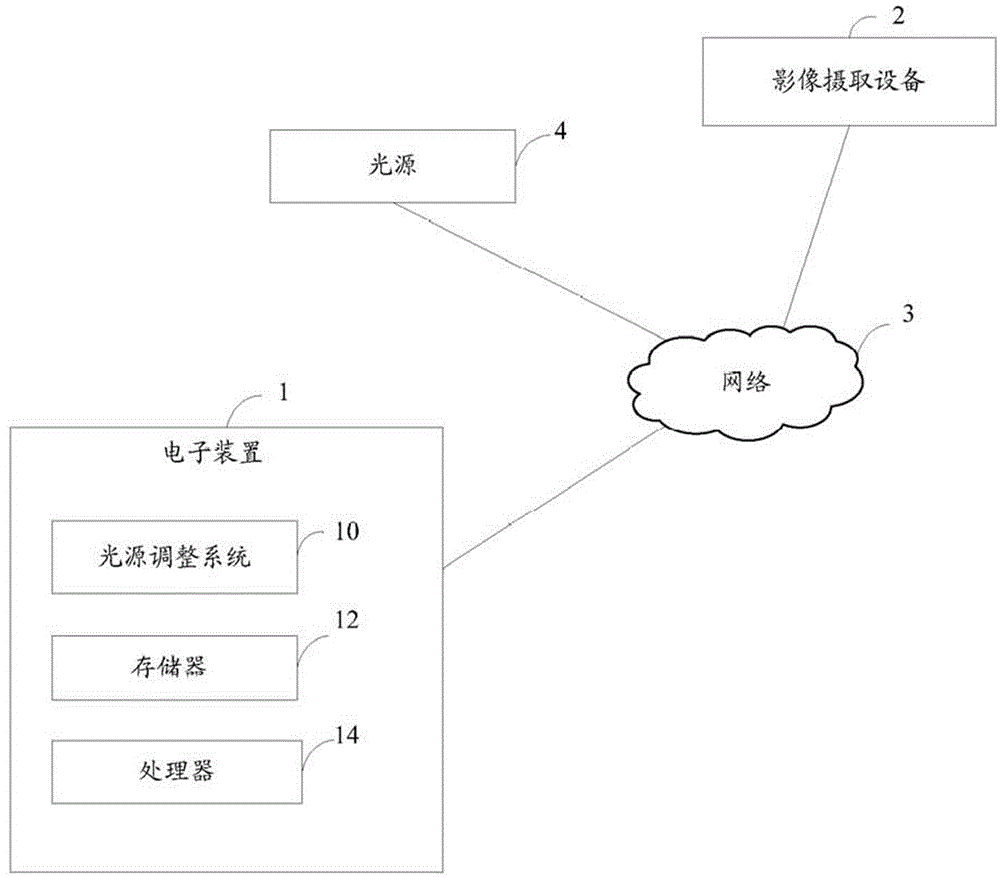

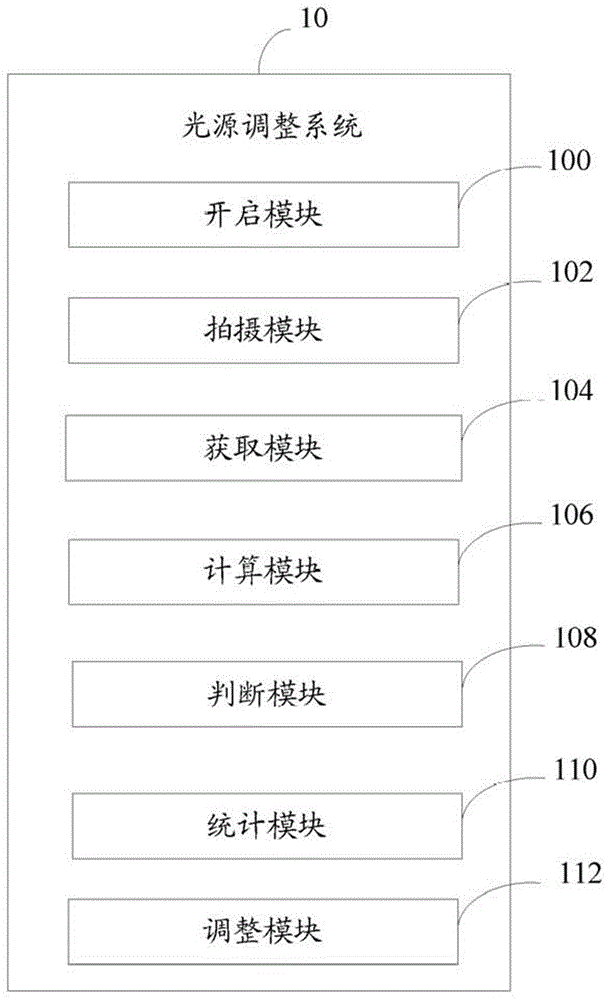

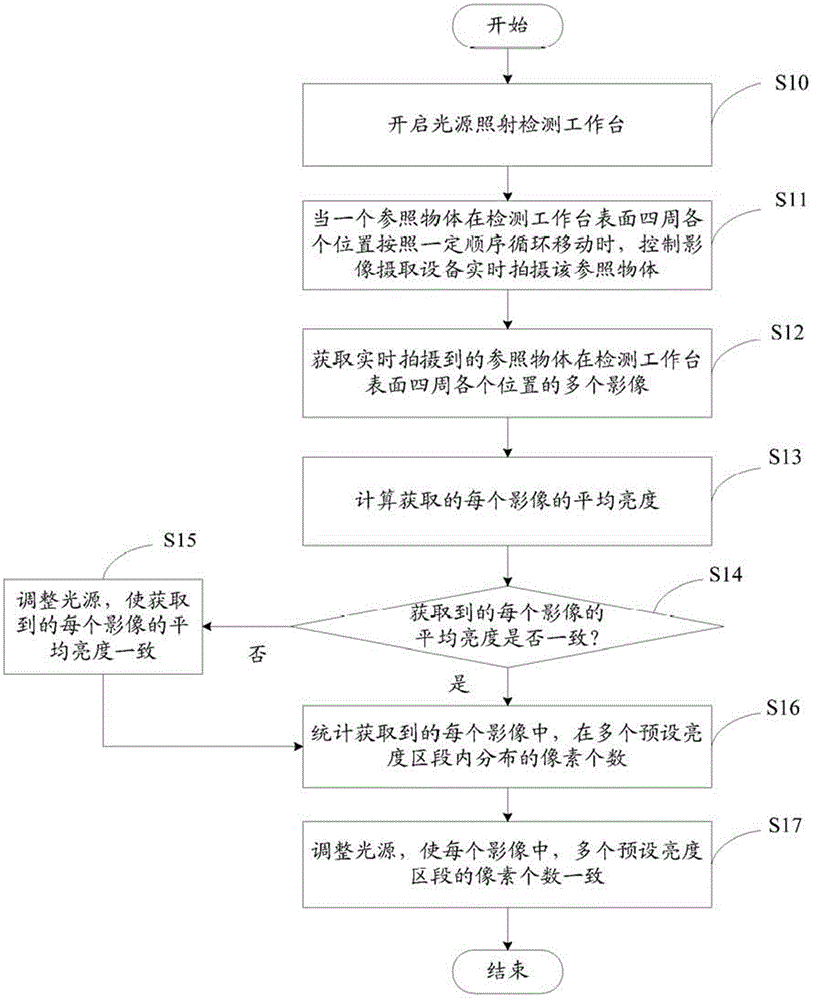

[0013] like figure 1 Shown is the operating environment diagram of the preferred embodiment of the light source adjustment system of the present invention. In this embodiment, the light source adjustment system 10 runs on an electronic device 1 , and the electronic device 1 is connected to the image capture device 2 and the light source 4 through the network 3 .

[0014] The electronic device 1 may be a computer, a smart phone, etc., and the electronic device 1 further includes a memory 12 and a processor 14 .

[0015] The image capture device 2 is used to capture a reference object (eg, a metal block) in real time when the reference object (eg, a metal block) moves cyclically in a certain order around the surface of the inspection table. The detection workbench is a platform on which objects to be measured are placed when automatic optical inspection (Automatic Optic Inspection, AOI) is performed.

[0016] The light source 4 can be an LED light source with an electric contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com