How to use water-saving ultrapure water machine

A pure water machine, pure water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve water waste, affect water purity, and pure water quality purity. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

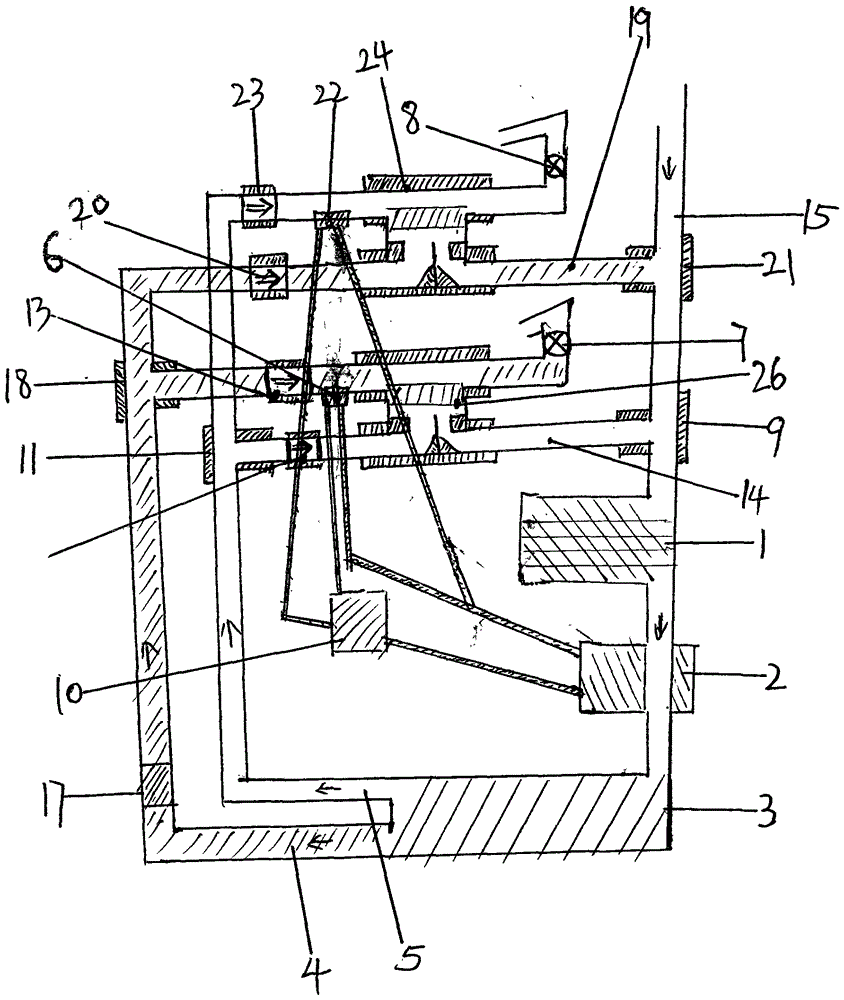

[0008] figure 1 The shown water-saving ultrapure water machine of the present invention is composed of a primary filter cartridge group 1, a water pump 2, an RO membrane group 3, and a power supply 10. The water inlet pipe 15 is sequentially connected to the primary filter cartridge group 1, water pump 2, RO membrane group 3; the pure water outlet pipe 5 is connected from the RO membrane group 3, and the concentrated water outlet pipe 4 is connected from the RO membrane group 3. According to the pure water outlet direction, there is a pure water pipe tee 11 on the pure water outlet pipe 5, and the pure water outlet pipe 5 is connected to the pure water one-way valve 23, the pure water high pressure switch 22 and the pure water outlet through the pure water pipe tee 11. The switch 8, the pure water pipe tee 11 is connected to the pure water flushing pipe 14 through the water inlet pipe pure water tee 9 and the water inlet pipe 15, and the pure water flushing pipe 14 has a pure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com