Seepage prevention method and structure for waste percolate collecting pool

A technology for leachate and waste, applied in infrastructure engineering, protection devices, building types, etc., can solve the problems of insufficient anchoring force of anchoring trenches, high pollution, tearing of HDPE membrane HDPE membrane, etc., to reduce the anchoring force. And HDPE film tensile stress is too large to ensure the effect of environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

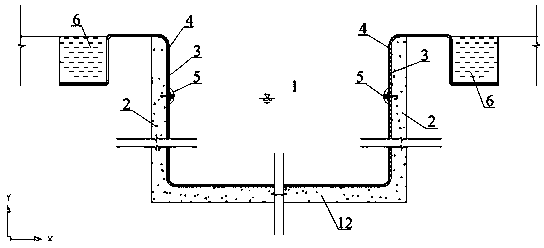

[0016] Such as figure 1 As shown, the structure of the present invention includes a pool 1 , a wall 2 , a bottom plate 12 , a geotextile 3 , an HDPE anti-seepage membrane 4 , an anchoring bead 5 and an anchoring ditch 6 . The anchoring ditch 6 is arranged outside the pool 1 and has a rectangular cross-section. Its depth is close to the bottom width, and its depth is about 1 / 4 to 1 / 3 of the depth of the pool 1 . The geotextile 3 and the HDPE anti-seepage membrane 4 are laminated and laid on the bottom plate 12 and the wall 2 of the pool 1 as a whole. The anchoring layer 5 is used to fix the geotextile 3 and the HDPE anti-seepage membrane 4 on the wall 2 of the pool 1 . The anchor layer 5 is arranged around the pool 1 .

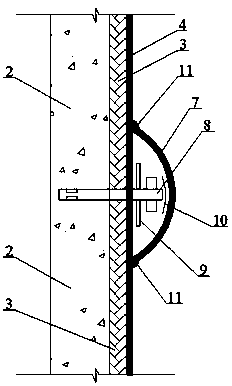

[0017] Look figure 2 The anchoring bead 5 includes an expansion bolt 8 driven into the wall 2 through the geotextile 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com