Mine downhole drilling well logging analysis meter and method

An analyzer and logging technology, applied in wellbore/well components, measurement, earthwork drilling, etc., can solve problems such as large quality impact, hole inclination, and deviation between drilling trajectory and design, and achieve accurate and low-cost results. Power consumption, meet the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

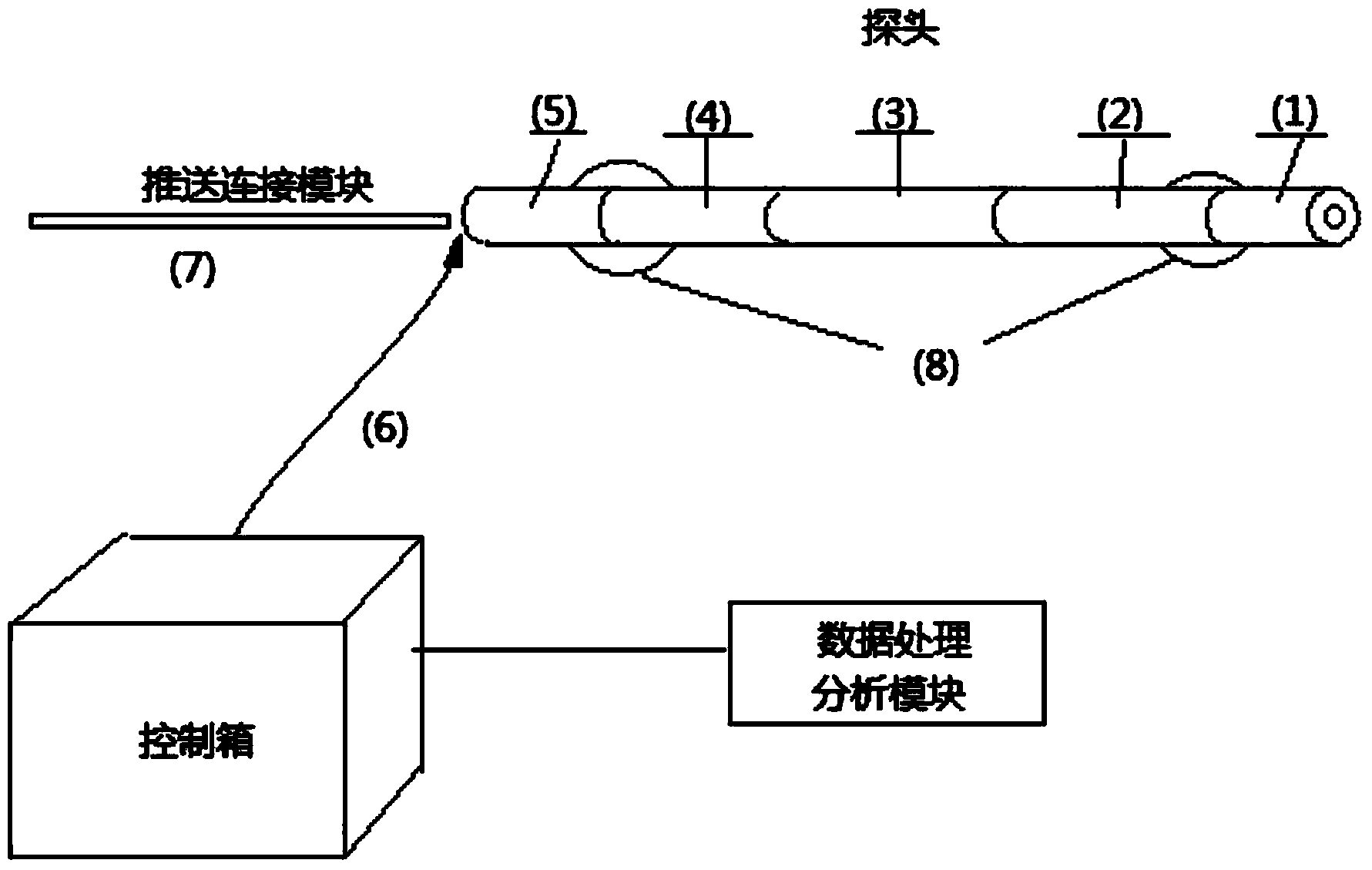

[0039] see figure 1 , a mine borehole logging analyzer, including a probe, a push rod 7, a connecting cable 6 and a control box.

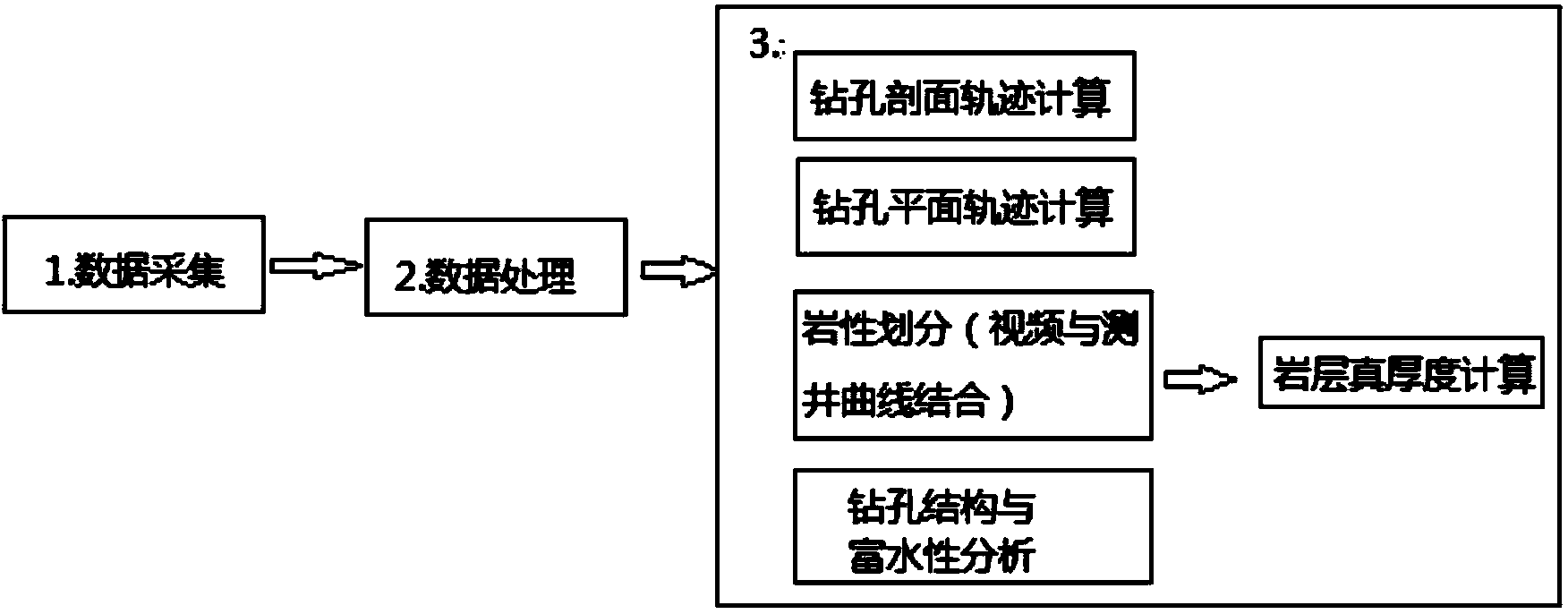

[0040] Wherein, the probe includes a metal casing and a transmission and control unit 4, a hole inclination measurement unit 3, a natural gamma unit 2 and a camera unit 1 which are arranged in the metal casing and are sequentially connected; the natural gamma unit 2 and the hole inclination measurement unit 3 respectively The collected data is sent to the transmission and control unit 4 for conditioning, and the data after conditioning is stored by the transmission and control unit 4 or sent to the control circuit unit in the control box for storage and / or display; the image collected by the camera unit 1 The data is sent to the control circuit unit in the control box through the connecting cable 6 or transmitted to the control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com