A method for checking initial readings of wind tunnel measuring equipment

A wind tunnel measurement and reading technology, which is applied in the field of aerodynamic wind tunnel tests in the aerospace industry, can solve problems such as difficult detection of deep-seated faults in measurement equipment, inability to check measurement equipment, and degradation of measurement data quality, so as to expand perspectives and data The effect of large quantity and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

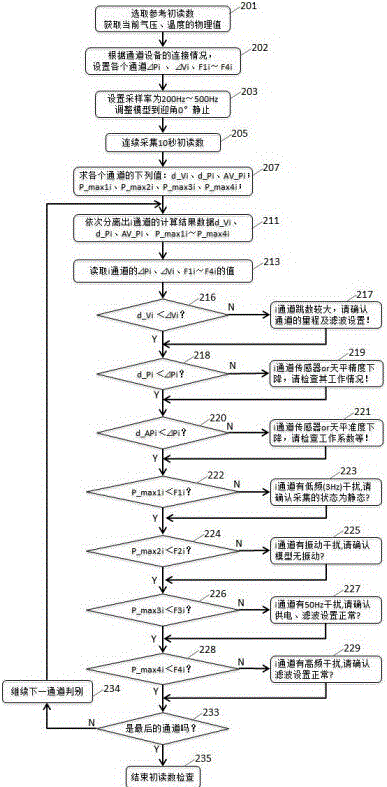

[0062] figure 1 It is a flowchart of a method for checking initial readings of wind tunnel measuring equipment in the present invention. The process includes the following steps:

[0063] Step 201, select the reference initial reading, select the initial reading of the test vehicle whose equipment status is normal and close to or consistent with the current test state as the reference initial reading; obtain the physical values of the current air pressure, temperature, etc. Obtain the physical values of the current air pressure and temperature through high-precision barometers, thermometers or atmospheric pressure sensors, temperature sensors, etc.;

[0064] Step 202, referring to Table 1, according to the situation and experience of the channel connected equipment, respectively set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com