Sand distribution device for preparing sand samples of different degrees of density in indoor model experiment

An indoor model and compactness technology, applied in the preparation of test samples, etc., can solve the problems of manpower and time consumption, small repeatability, and low reliability of test results, so as to save manpower and time and realize precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

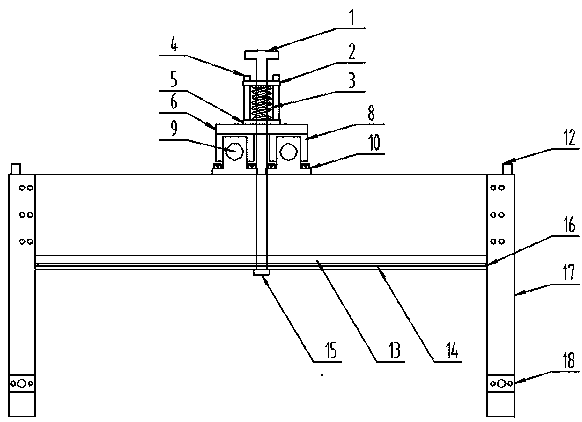

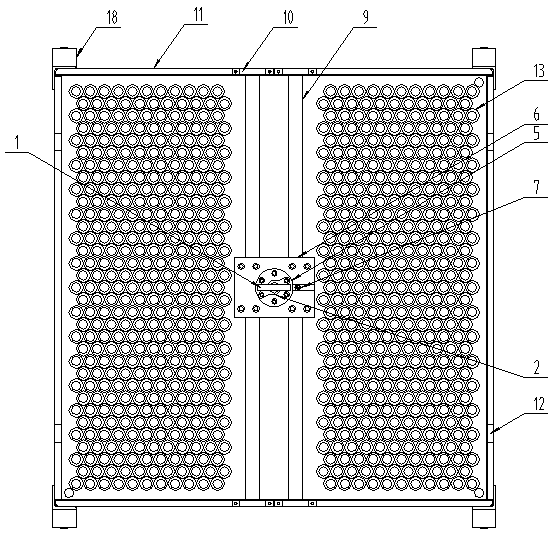

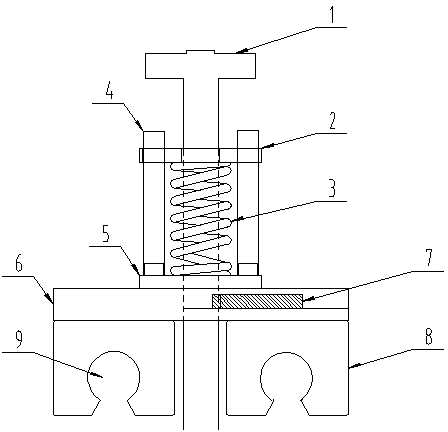

[0023] Such as figure 1 , 2 , 3 and 4, the present invention includes the control lever 1 of the opening and closing mechanism, the compression spring fastener 2, the compression spring 3, the fastener connecting rod 4, the spring bottom plate 5, the control lever anti-rotation key 7, the control Rod stopper 15, trolley platform plate 6 and slider 8 of the trolley platform, guide rail 9 of the sand shakeout box, guide rail support seat 10, side plate 11 of the sand shakeout box, suspension ring 12, sand leaking plate 13, and sand retaining plate 14 , low-resistance spring hinge 16, and the angle steel support leg 17 of support frame, anti-rebound pin 18.

[0024] The sand shakeout box is composed of four rectangular sand shakeout box side panels 11 and the sand drain plate 13. A series of circular or conical holes for sand leakage are distributed. The distance between the sand leakage hole and the center of the hole is 30mm, and the diameter of the circular hole is 20mm. It ...

Embodiment 2

[0030] The structure of this device is the same as embodiment 1.

[0031] In the test, the compactness of the prepared sand samples was controlled by exchanging sand drain plates with different bottom plate hole diameters and hole spacing types, adjusting the height of falling sand, and the particle size of sand. Sand samples with different densities can be prepared by using a sand leak board with a round hole diameter of 20mm, 10mm, 5mm or a round hole with a tapered guide hole. Through the changes of the above three different diameters, the falling sand test is carried out to achieve the result of controlling the different compactness of sandy soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com