Construction waste crushing device

A technology of crushing device and construction waste, applied in grain processing and other directions, can solve the problems of low crushing strength, large wasted power loss, limited hitting efficiency, etc., and achieve the effect of high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

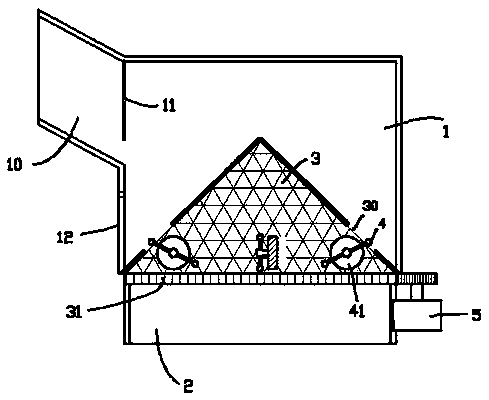

[0012] exist figure 1 , figure 2 In the shown embodiment, the construction waste crushing device includes a crushing chamber 1, the upper part of the crushing chamber 1 is provided with a feed port 10; a one-way door 11 is also provided at the feed port 10, and its opening direction is from the From the outside of the crushing chamber 1 to the inside, prevent the fragments in the crushing chamber 1 from splashing out.

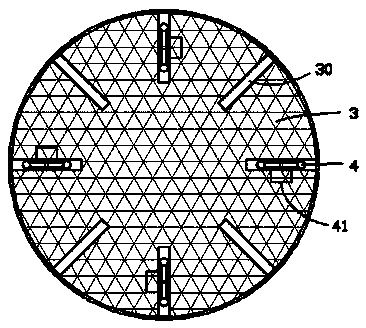

[0013] The lower part of the crushing chamber 1 is provided with a conical sieve screen 3 with the cone facing upwards; the lower part of the sieve screen 3 is the discharge chamber 2; Position holes 30; the bottom of the sieve mesh plate 3 is evenly distributed with breakers 4 rotating in a vertical plane; in this embodiment, the breakers 4 are driven by a breaker motor 41, and the sweeping surface of the breaker extends to Above the strip-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com