A kind of manufacturing method of subway evacuation platform board

An evacuation platform and a manufacturing method technology, applied in the field of building materials, can solve the problem that the subway evacuation platform plate is difficult to meet the use requirements, and achieve the effects of good anti-seepage and anti-freezing performance, long service life and good cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The raw materials used in the following examples are:

[0030] The composition ratio of high-activity admixture is: microsilica fume, S95 mineral powder, and high-activity catalyst in a weight ratio of 4:4:1; the composition ratio of high-activity catalyst is: defoamer, triethanolamine, sodium formate, sulfur The aluminate cement is 1:0.02:0.06:0.5 by weight. The micro-silica powder is selected with an average particle size of 0.30 μm, SiO 2 Microsilica fume with a content ≥ 92%; the defoamer is a powdered defoamer based on organically modified siloxane; the sulphoaluminate cement is 42.5 grade rapid hardening sulphoaluminate cement;

[0031] Quartz sand is a continuous graded fine quartz sand with three particle sizes of 1.25-0.63mm, 0.63-0.315mm and 0.315-0.165mm, SiO 2 The content is greater than 97%.

[0032] The steel fiber is a straight galvanized steel fiber with a circular cross-section and a straight end with a tensile strength greater than 2850MPa, with a d...

Embodiment 2

[0044] An active powder concrete evacuation platform slab is formed by combining cement, high-activity admixture, quartz sand, steel fiber, water reducing agent and water in a certain proportion and pouring steel mesh. The dosage of each component of the evacuation platform board is: cement 670kg, high activity admixture 230kg, quartz sand 1320kg, steel fiber 45kg, water reducing agent 13.5kg, water 174kg, the measurement unit is kg / m 3 .

[0045] The manufacture method of subway evacuation platform plate is used except that each component content is different from embodiment 1, and other are all the same.

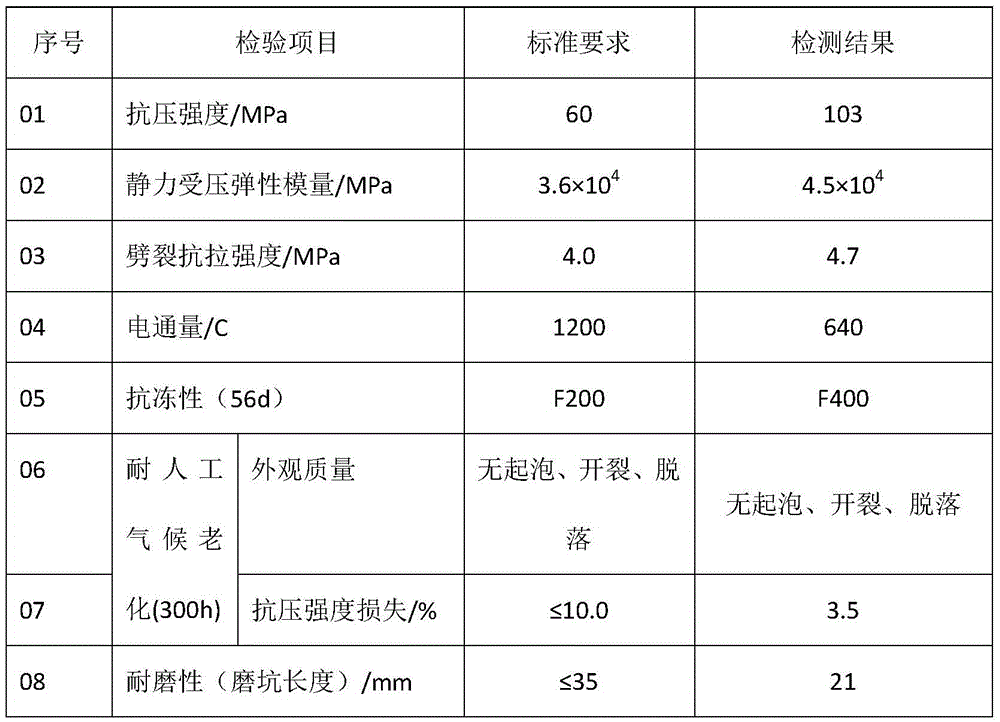

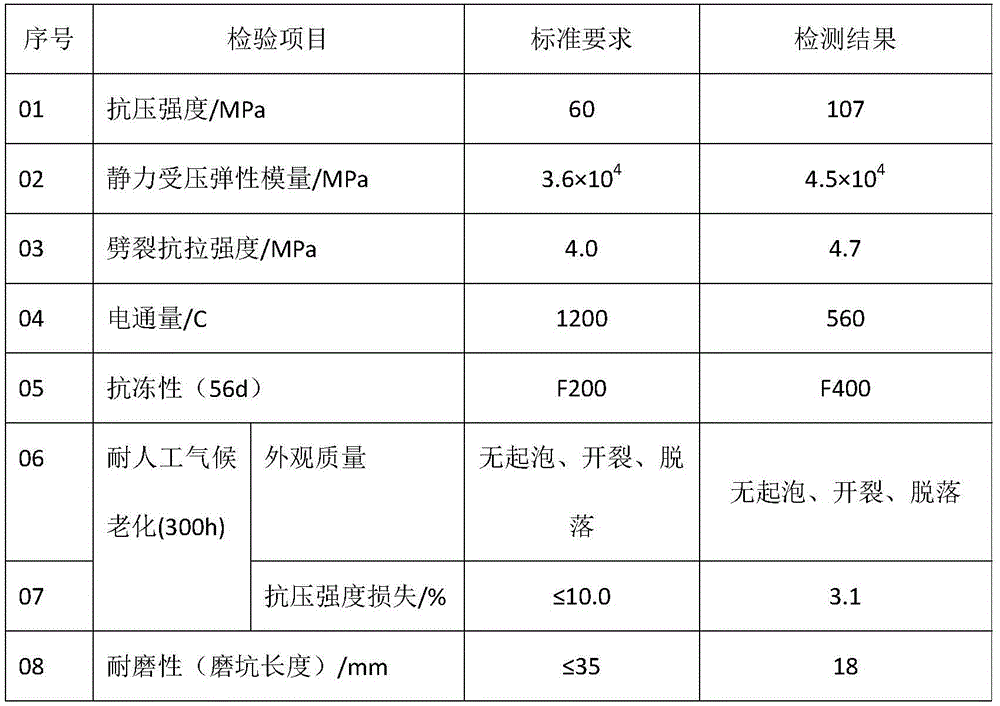

[0046] The performance test results of the subway evacuation platform plate prepared in embodiment 2 are shown in table 2.

[0047] Table 2

[0048]

Embodiment 3

[0050] An active powder concrete evacuation platform slab is formed by combining cement, high-activity admixture, quartz sand, steel fiber, water reducing agent and water in a certain proportion and pouring steel mesh. The dosage of each component of the evacuation platform board is: cement 710kg, high activity admixture 240kg, quartz sand 1300kg, steel fiber 45kg, water reducing agent 28kg, water 167kg, the measurement unit is kg / m 3 .

[0051] The manufacture method of subway evacuation platform plate is used except that each component content is different from embodiment 1, and other are all the same.

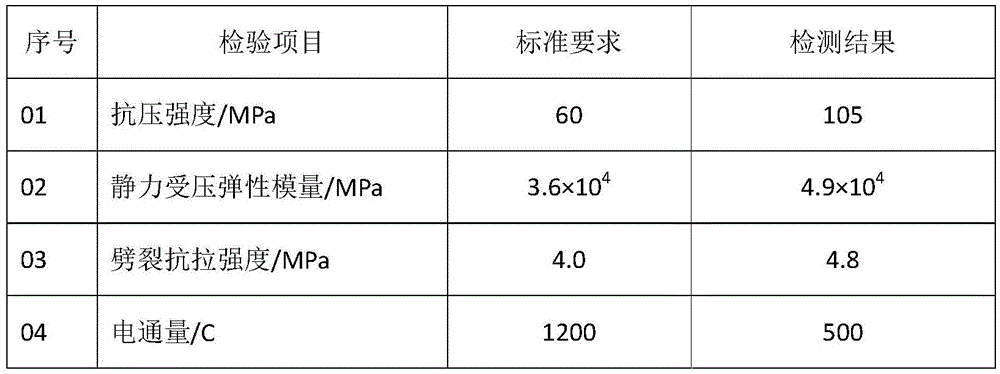

[0052] The performance test results of the subway evacuation platform plate prepared in embodiment 3 are shown in table 3.

[0053] table 3

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com