Anti-blocking grease gun

A grease gun and anti-clogging technology, which is applied in the direction of manual lubricant supply, engine components, engine lubrication, etc., can solve the problems that the oil outlet is easily blocked, affects work efficiency, and wastes time, and achieves a simple and reasonable structure. Improve work efficiency, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

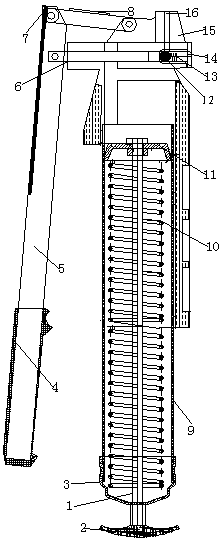

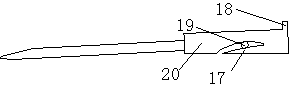

[0010] The anti-clogging grease gun comprises an oil cylinder 9, a casting nozzle 15 arranged at one end of the oil cylinder and a handle 5 arranged on one side of the oil cylinder, the handle is movably connected with the casting nozzle through a connecting piece 8, and the casting nozzle is provided with The exhaust valve that steel ball 12, one-way valve spring 13 and plug screw 14 constitute. The handle is connected to the inside of the oil cylinder through the piston 6, and the inside of the oil cylinder is equipped with an oil pushing assembly composed of a pull rod 1, a pressure spring 10, and a rubber bowl 11. The back cover 3 presses the oil pushing assembly and is connected to the other end of the oil cylinder, and one end of the pull rod is connected to a handle 2. The handle is provided with a rubber handle cover 4.

[0011] The handle is provided with a through needle 7, and one end of the handle is provided with a through needle installation hole, the through ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com