Electric water heater control method

An electric water heater and control method technology, applied in the electrical field, can solve the problems of high current and power, device damage, electric water heater circuit overload, etc., and achieve the effects of prolonging life, improving safety, and avoiding excessive current and power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

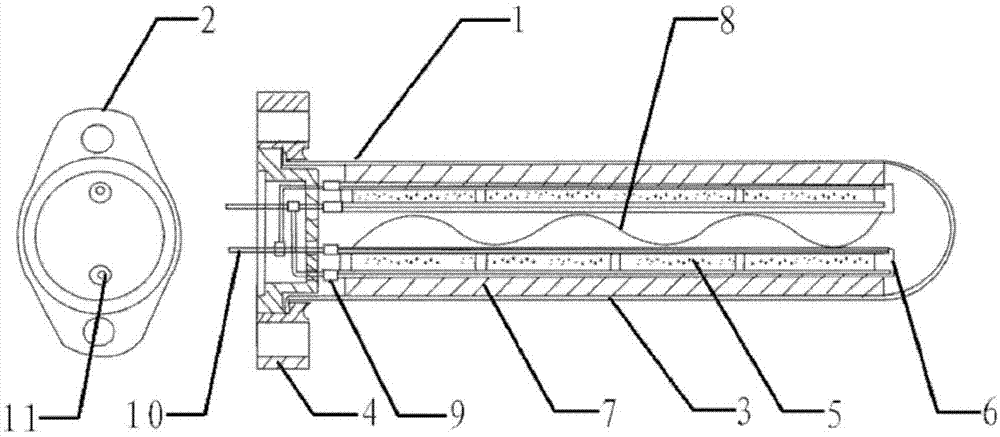

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

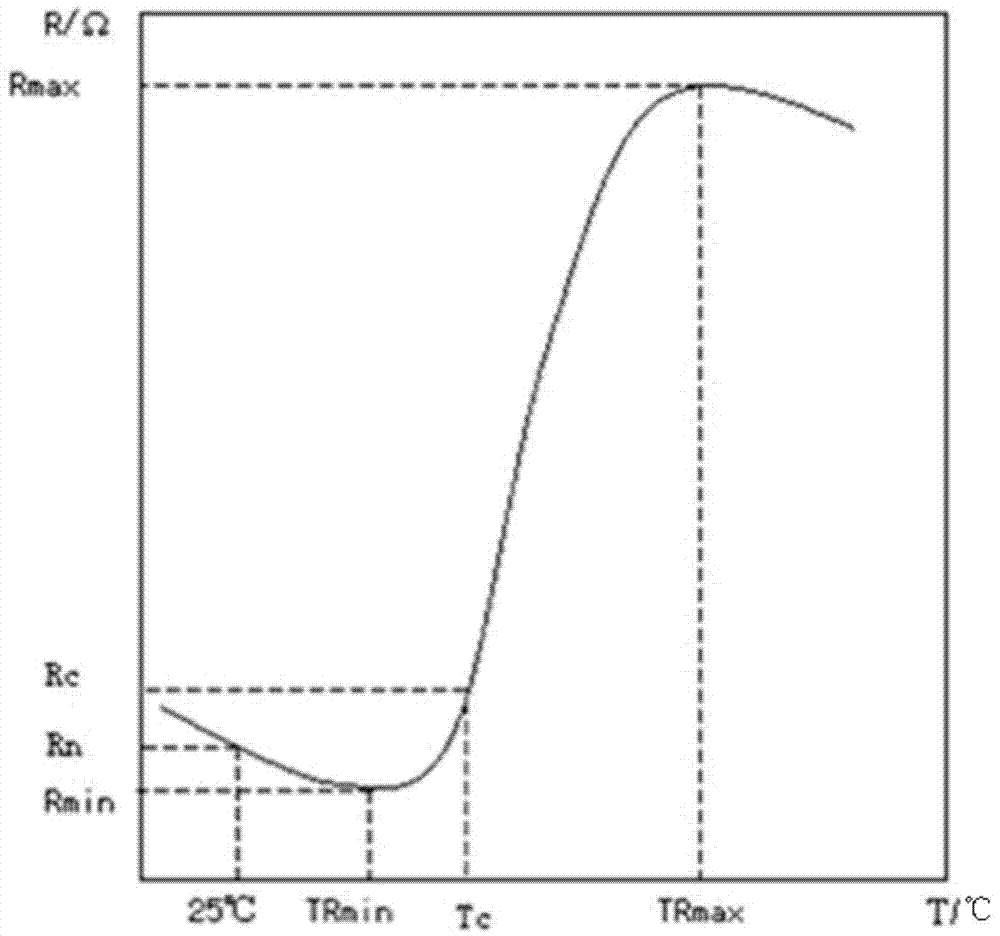

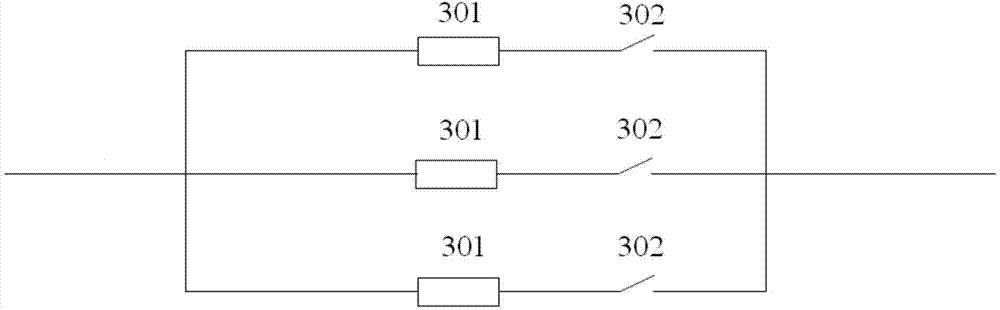

[0025] The inventors found that in the prior art, after the electric water heater is powered on, multiple PTC heating elements start to work at the same time, which may cause excessive current and power, overload the circuit of the electric water heater, and damage the device. figure 2 It is the resistance-temperature (R-T) curve diagram of the PTC heating element in the embodiment of the present invention. figure 2 Among them, Rn is the rated temperature zero power resistance, Rmin is the minimum zero power resistance, TRmin is the temperature at the minimum resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com