Liquid cooling source unit with function of precisely controlling temperature and control method

A technology of precise control and liquid cooling source, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem of low temperature control accuracy, achieve high temperature control accuracy, high-precision temperature control, and realize real-time electric control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

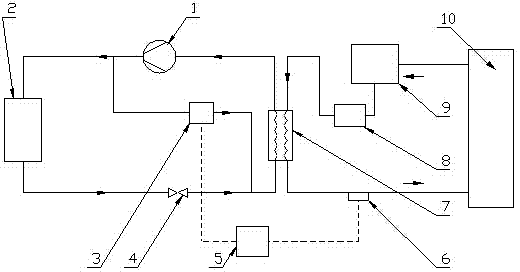

[0034] like figure 1 As shown, a liquid cooling source unit with precise temperature control includes a compressor 1, a condenser 2, an evaporator 7, and a heating device 10, and the liquid outlet of the evaporator 7 is connected to the liquid inlet of the compressor 1; The exhaust port of the compressor 1 is connected to the air inlet of the condenser 2; an electronically controlled valve 3 is also provided between the exhaust port of the compressor 1 and the liquid inlet of the evaporator 7, through which the electronically controlled valve 3 Real-time electric control of the additional heat load can be realized by adjusting the adjustment, and finally the total heat load can be matched with the cooling capacity, so as to ensure a precisely controlled liquid supply temperature for the use side; the liquid outlet of the condenser 2 is connected with the inlet of the evaporator 7 The liquid port is connected; a throttling device 4 is provided between the condenser 2 and the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com