Method for preparing alpha-metylene lactone

A technology of methylene lactone and production method, applied in the direction of organic chemistry and the like, can solve the problems of polluted reactor, unsuitable for large-scale production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] The present invention relates to a process for the production of α-methylene lactone comprising the steps of producing an enolate intermediate from the lactone and reacting the enolate intermediate with paraformaldehyde in order to obtain α-methylene in high yield The step of base lactone.

[0032] The present invention relates to a process for the production of α-methylene lactone comprising the steps of: (A) the step of producing an enolate intermediate by reacting the lactone with an alkyl formate in the presence of an alkoxide base; and (B) The enolate intermediate is reacted with paraformaldehyde. As a specific embodiment of the present invention, the α-methylene lactone of the present invention can be produced by the reaction represented by Reaction Formula 3.

[0033] [reaction formula 3]

[0034]

[0035] The present invention is specifically described below.

[0036] (A) Enolate intermediate production steps

[0037] In the present invention, the enola...

Embodiment 1

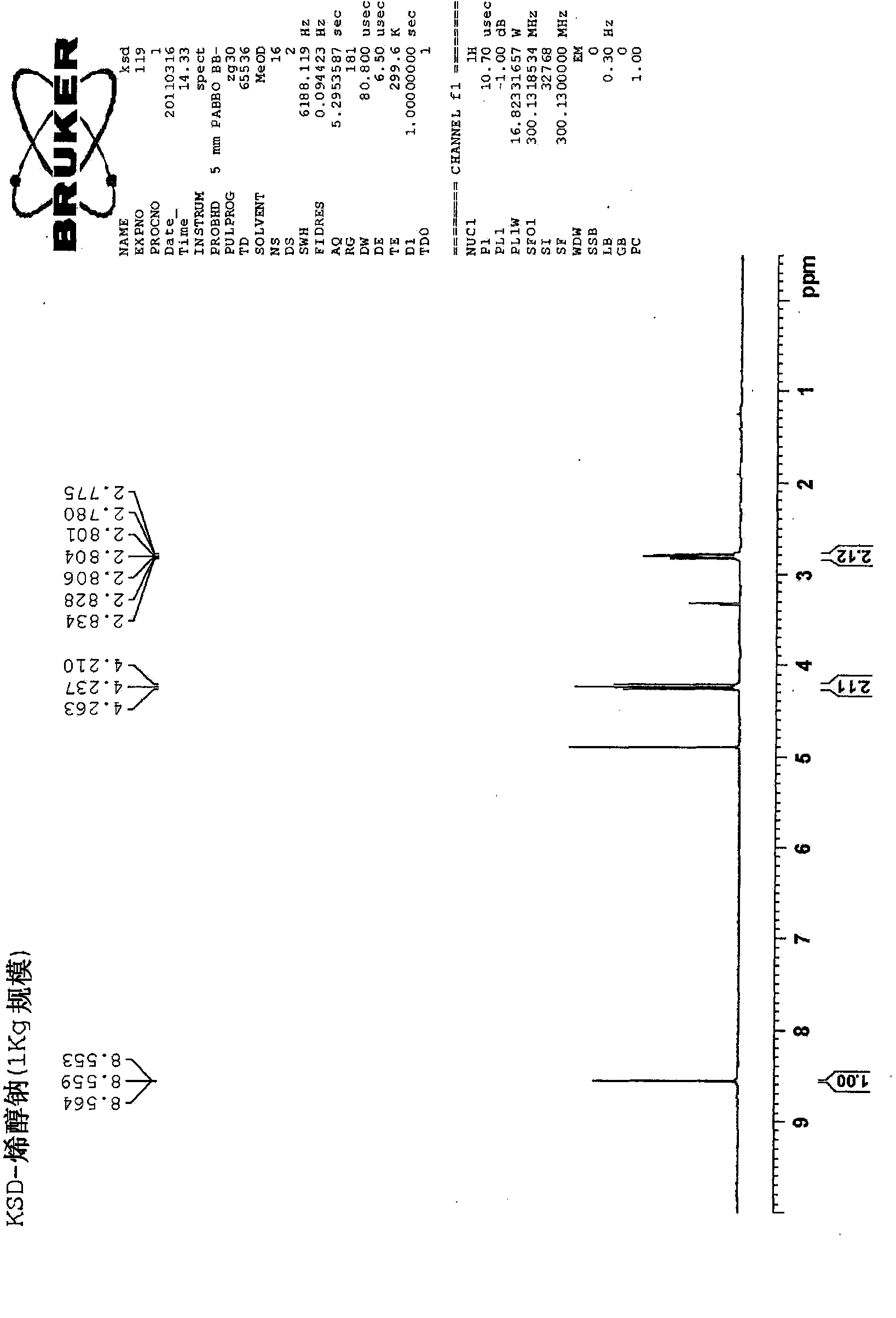

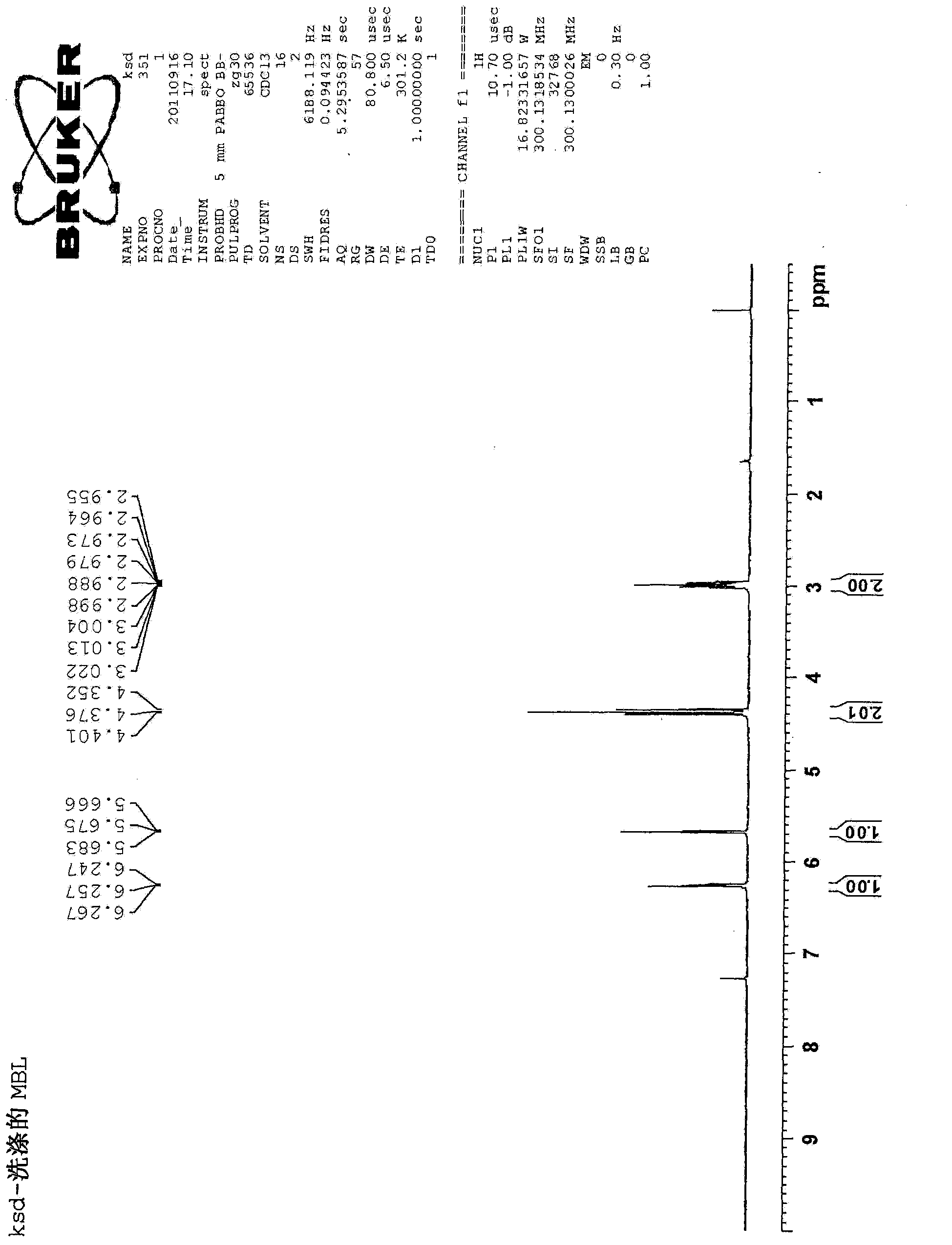

[0069] Sodium ethoxide (395 g, 5.81 mol) and 3.5 L of tetrahydrofuran (THF) as solvents were placed in a 5 L reactor, and the mixture was stirred at 115 rpm while maintaining the temperature of the reactor at 17°C. Ethyl formate (645 g, 8.72 mol) was quickly placed in the reactor, and γ-butyrolactone (500 g, 5.81 mol) was slowly added dropwise into the reactor over 1 hour and 30 minutes. When γ-butyrolactone is added dropwise to the reactor, the internal temperature of the reactor does not exceed 30°C, and, when γ-butyrolactone is added dropwise under stirring, the internal temperature of the reactor is kept at 17°C for 20 hours . After the reaction was completed, the precipitated compound was filtered using 3 μm filter paper, and washed with THF. The filtered compound was dried in a vacuum oven at 60°C, and α-formyl-γ-butyrolactone sodium salt was synthesized.

Embodiment 2

[0071] α-Formyl-γ-butyrolactone sodium salt was synthesized by the same method as in Example 1, except that the mixture was stirred at a speed of 115 rpm and a filter paper of 1 μm was used for filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com