Six-freedom-degree satellite-borne instrument mounting device capable of being fine-tuned

A degree of freedom and space-borne technology, applied in the field of star-mounted devices, can solve the problems of high labor intensity, high risk, and low operating efficiency, and achieve the effects of reduced labor intensity, not easy to scratch, accurate and fast positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

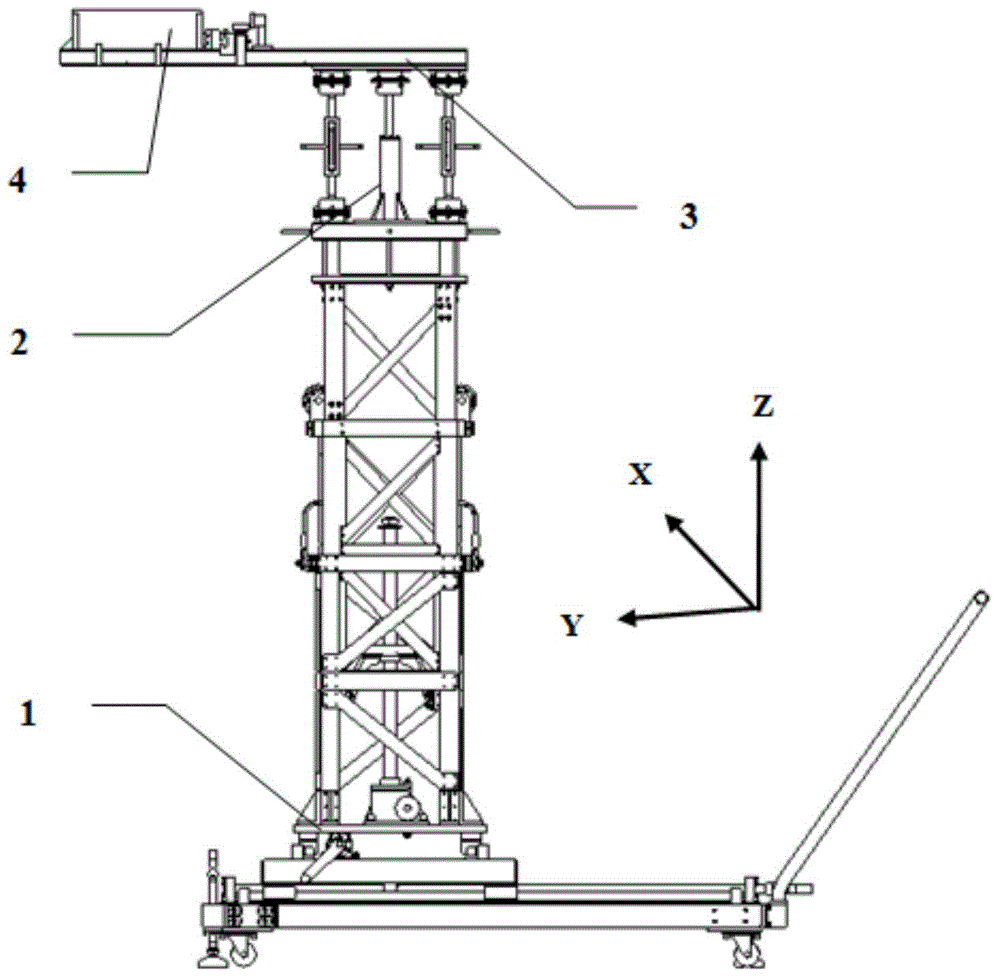

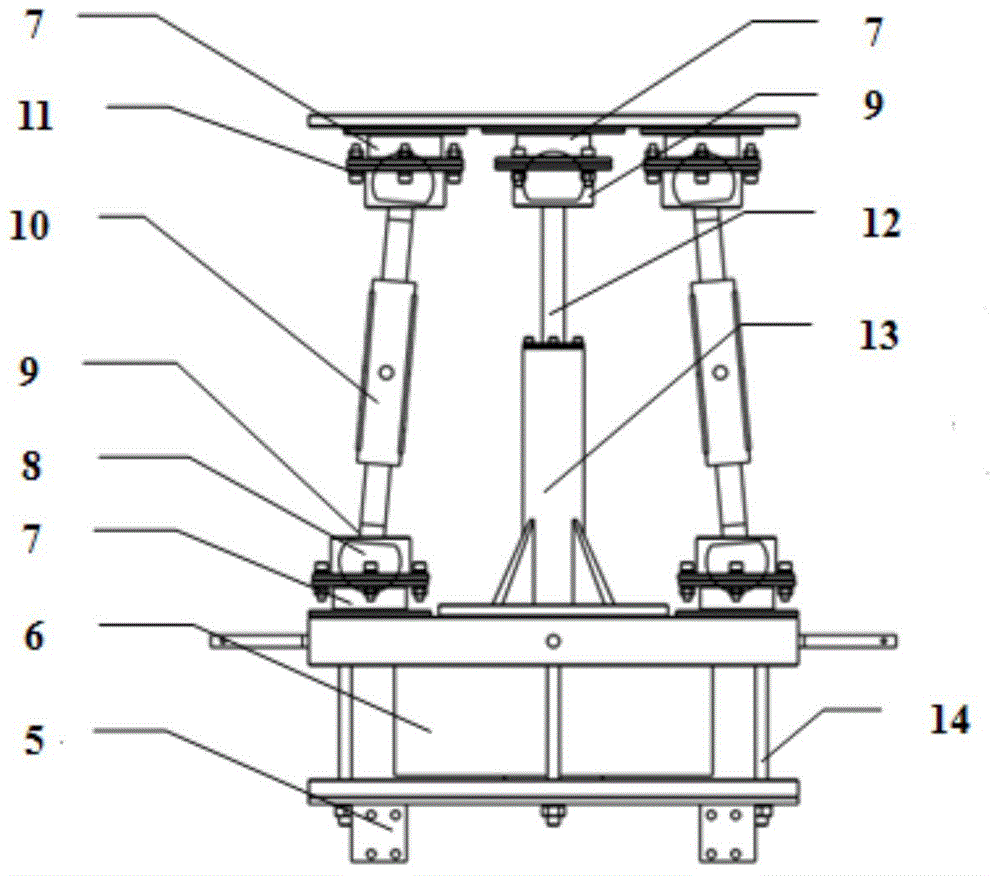

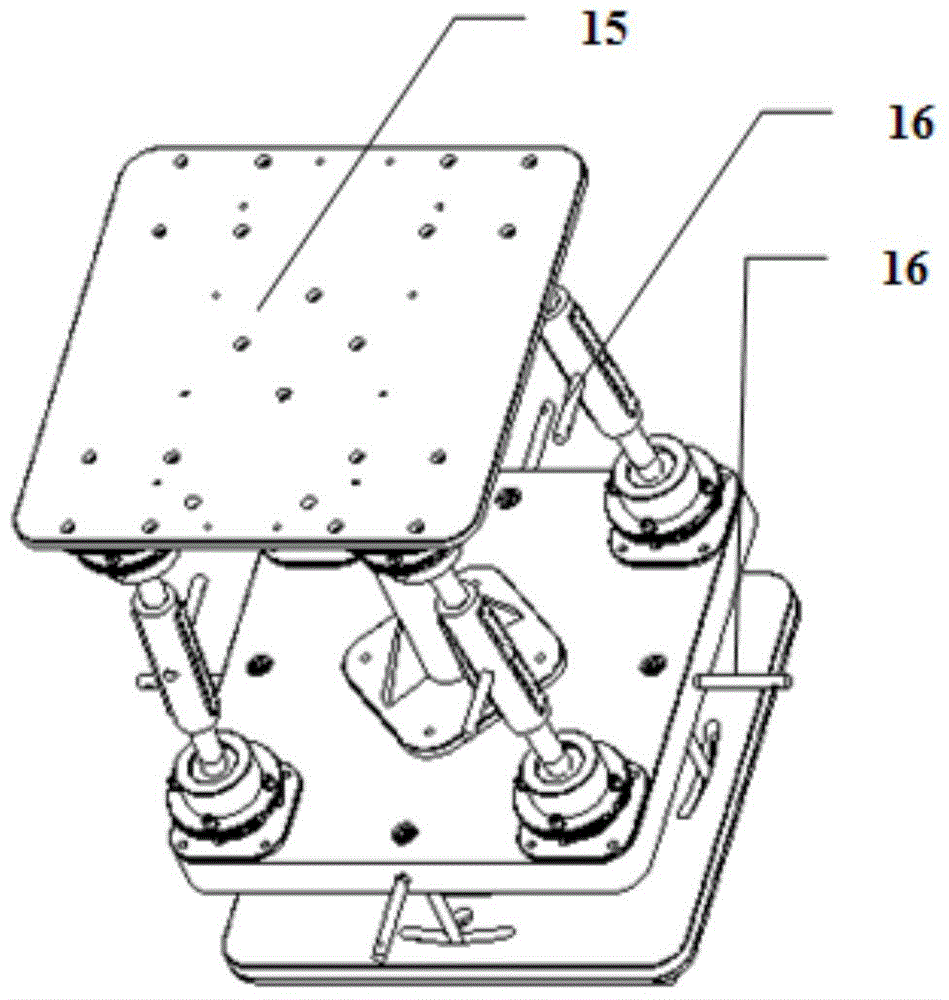

[0021] Such as Figure 1 to Figure 5 As shown, the present invention can fine-tune the six-degree-of-freedom satellite-borne instrument installation device including a three-degree-of-freedom adjustment base 1, a four-degree-of-freedom attitude adjustment mechanism 2, and a space-borne instrument clamping device 3. The bottom end of the DOF attitude adjustment mechanism 2 is fixed, specifically by connecting the corner pieces 5 and bolts; the top end of the four DOF attitude adjustment mechanism 2 is fixed with the bottom end of the spaceborne instrument clamping device 3, specifically four The upper platform 15 of the degree-of-freedom attitude adjustment mechanism 2 and the bottom plate 17 of the space-borne instrument clamping device 3 are fixed by bolts, and the space-borne instrument 4 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com