Full-automatic packaging machine

A fully automatic packaging machine and sliding seat technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of insensitivity, waste of cost, and inconvenient use of packaging machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

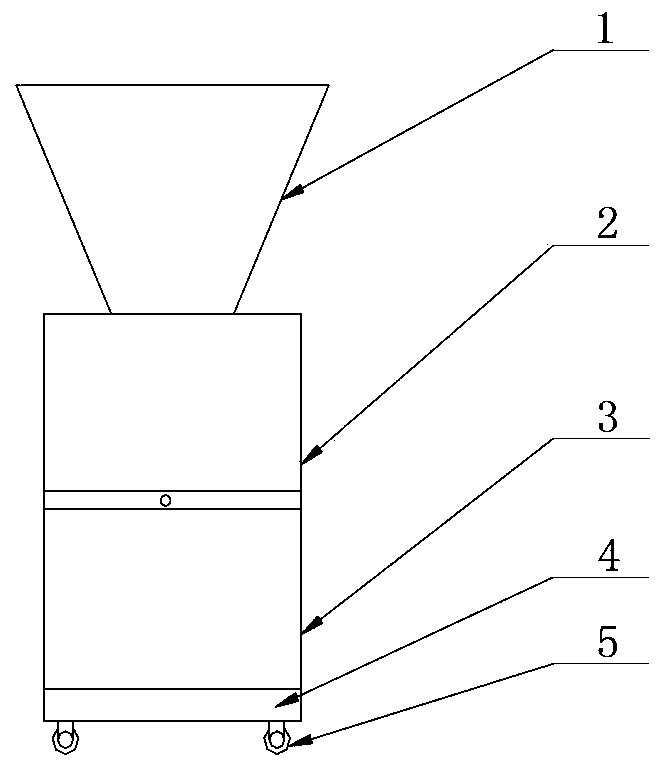

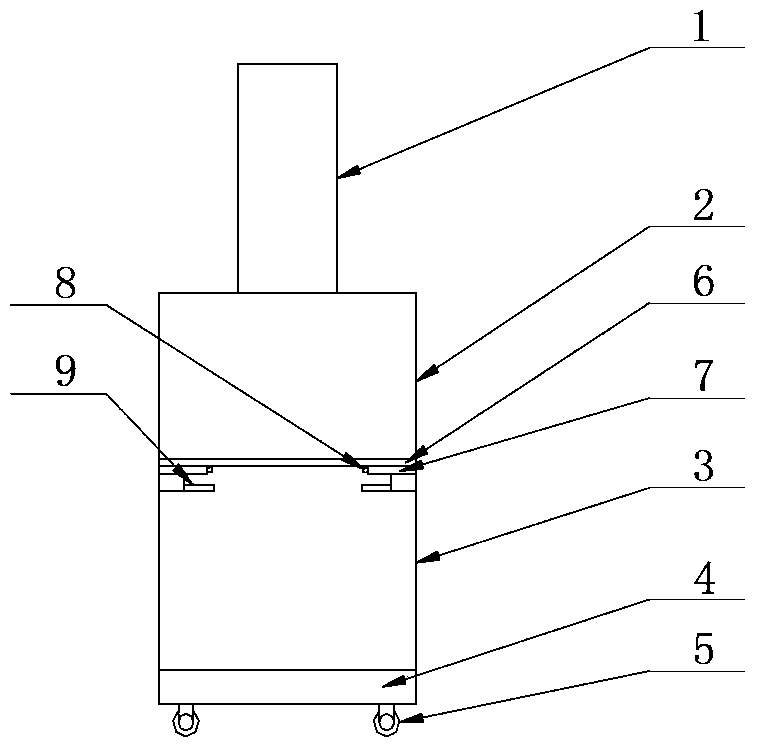

[0011] see Figure 1-Figure 2 , the specific embodiment adopts the following technical scheme: it includes a feeding funnel 1, a housing 2, a base 3, a weighing device 4, a roller 5, an electric guide rail 6, a sliding seat 7, a vacuum sucker 8, a heat seal body 9, and the housing 2 A feeding funnel 1 is installed on the top of the shell 2, a base 3 is installed on the bottom of the shell 2, a weighing device 4 is installed on the base 3, rollers 5 are installed at the four corners of the bottom of the base 3, and an electric guide rail 6 is installed on the lower end of the shell 2. Both ends of the electric guide rail 6 are equipped with sliding seats 7 , heat seals 9 are installed at the lower ends of the two sliding seats 7 , and vacuum suction cups 8 are installed at one end of the two sliding seats 7 .

[0012] The front end of the heat-seal body 9 is arranged in a knurled shape.

[0013] In this specific embodiment, the bag is placed on the base 3, the mouth of the bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com