Smokeless and dust-removing drying oven having biomass as fuels and used for producing organic fertilizers

A drying furnace and organic fertilizer technology, applied in drying, drying machines, heating devices, etc., can solve the problems of polluting the environment, increasing production costs, etc., and achieve the effect of reducing heat loss and ensuring the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

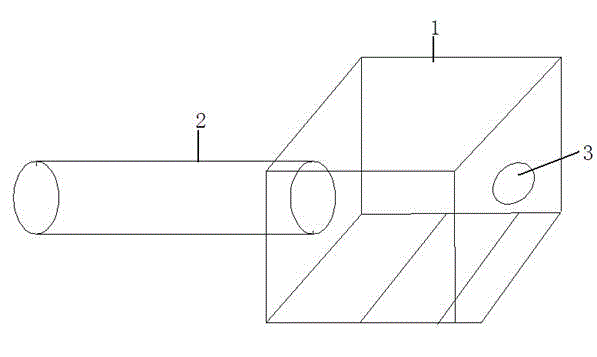

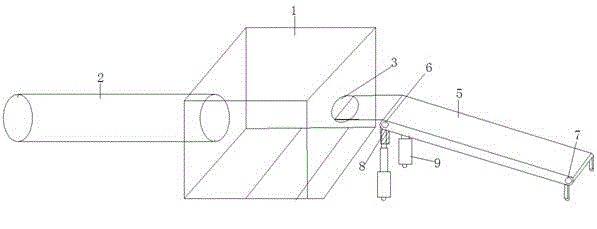

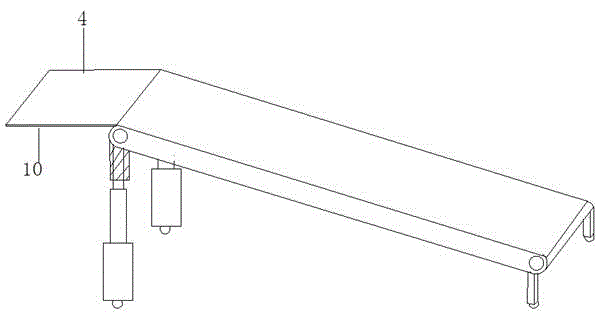

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes that the drying furnace 1 is directly connected with the drying cylinder 2, and the buffer section is removed. On the one hand, the dust generated after biomass combustion and the organic fertilizer particles are better integrated during the drying process to achieve dust production. The effect of particles; on the other hand, it reduces heat loss and ensures the drying effect. The furnace body is 2-3m high, 2.5-3.5m long and 3-4m wide, in a cuboid structure. A feed inlet 3 is provided on the surface of the furnace facing the drying cylinder 2, and the fuel used is biomass fuel, which avoids pollution to the environment. There are three areas (ABC area) between the drying cylinder 2 and the feed port 3. Area A is the feeding area, area B is the buffer drying area, and area C is the combustion area. The heat and dust generated by combustion directly enter the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com