Method and equipment for manufacturing smilax bockii warb granules

A manufacturing method, the technology of King Kong, is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, and devices for making drugs into special physical or ingestible forms, which can solve the problems of low utilization rate of Chinese herbal medicines and improve the utilization of raw materials rate, efficiency improvement, drug safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

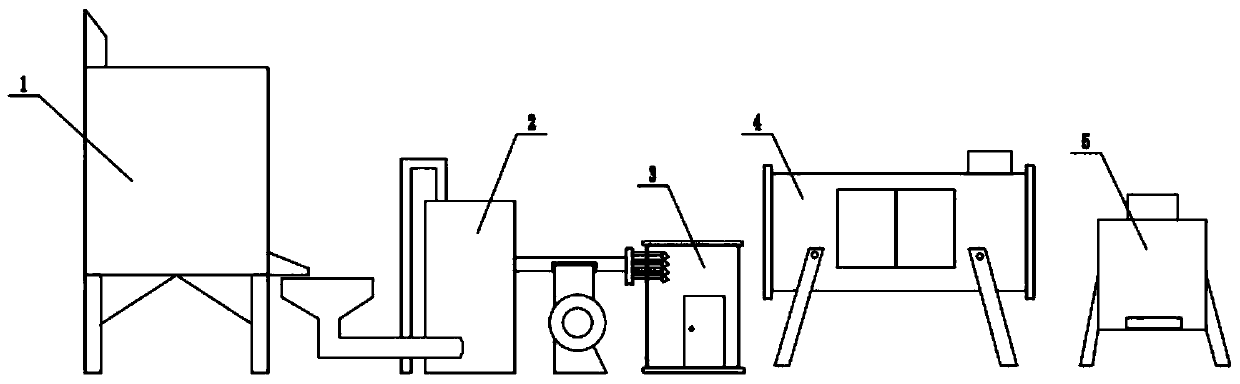

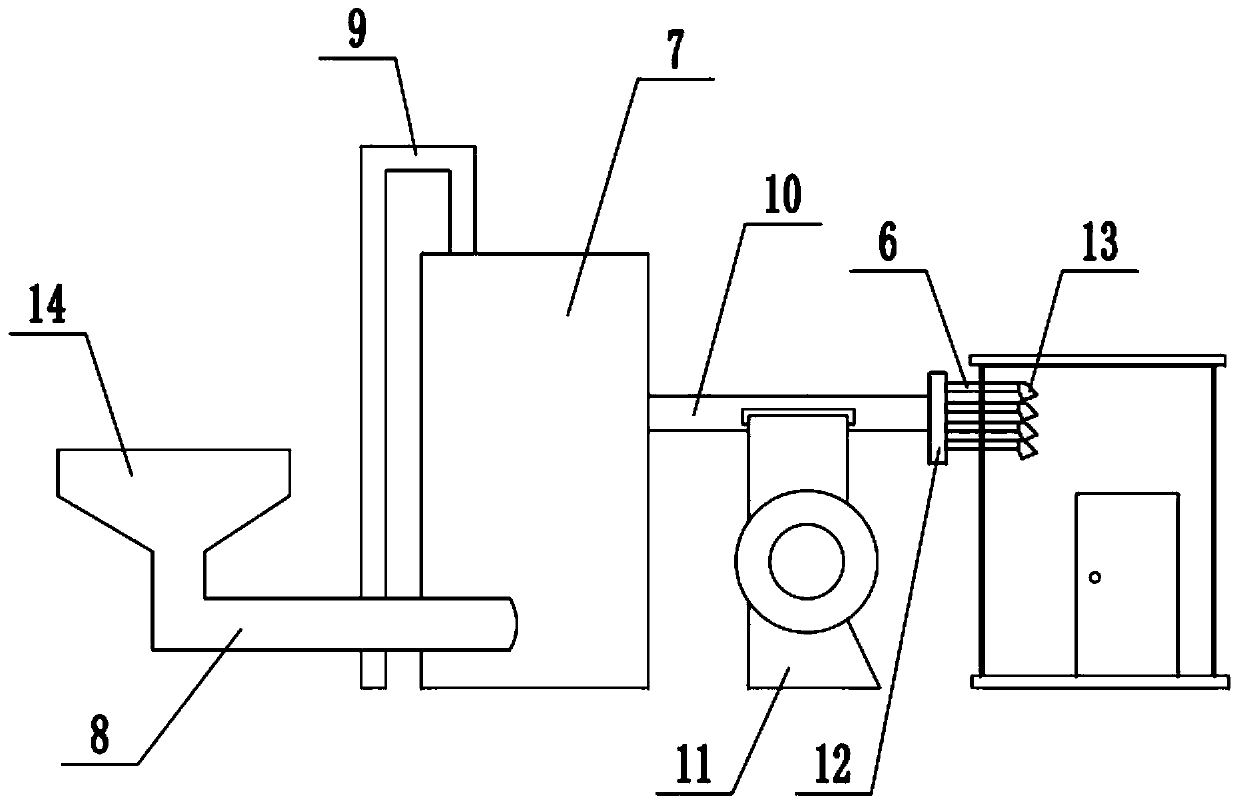

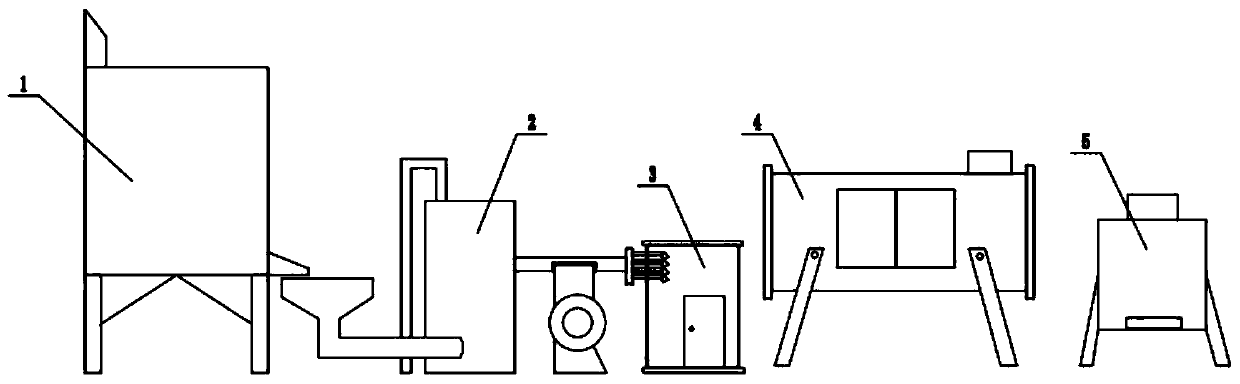

[0023] A kind of manufacture method and equipment thereof of King Kong rattan granules, comprising the steps of:

[0024] (1) Wash the fresh vine leaves with clear water, spread them in a cool place and dry them in the shade for later use;

[0025] (2) Send the vine vine belt leaves after drying in the shade to the crushing equipment to obtain the paste vine vine material after 180 mesh sieves, and the vine vine juice produced in the crushing process is collected by a reflux spray device for subsequent use;

[0026] (3) Send the paste-like rattan vine material into the moisture resurgence bin for spraying and rehydration for 2 hours. The spray liquid used in the resurgence bin is obtained by mixing the rattan vine juice collected by the backflow spraying equipment and tap water according to the ratio of parts by weight of 1:10. The relative humidity in the damp chamber is 90%;

[0027] (5) Send the paste-like diamond rattan material after moisture regaining into the dryer for...

Embodiment 2

[0032] A kind of manufacture method and equipment thereof of King Kong rattan granules, comprising the steps of:

[0033] (1) Wash the fresh vine leaves with clear water, spread them in a cool place and dry them in the shade for later use;

[0034] (2) Send the vine vine belt leaves after drying in the shade to the pulverizing equipment to obtain pasty vine vine material after 195 mesh sieves, and the vine vine juice produced in the crushing process is collected by a reflux spray device for subsequent use;

[0035] (3) Send the paste-like vine vine material into the moisture resurgence bin for spraying and rehydration for 4.5 hours. The spray liquid used in the resurgence bin is obtained by mixing vajra vine juice collected by the backflow spraying equipment with tap water at a ratio of 1:10 by weight. , the relative humidity in the damp chamber is 95%;

[0036] (5) Send the paste-like King Kong rattan material after moisture regaining into the dryer for low-temperature dryin...

Embodiment 3

[0041] A kind of manufacture method and equipment thereof of King Kong rattan granules, comprising the steps of:

[0042] (1) Wash the fresh vine leaves with clear water, spread them in a cool place and dry them in the shade for later use;

[0043] (2) Send the vine vine belt leaves after drying in the shade to the pulverizing equipment to obtain pasty vine vine material after 200 mesh sieves, and the vine vine juice produced in the crushing process adopts a backflow spraying device to collect for subsequent use;

[0044] (3) Put the mushy King Kong rattan material into the moisture resurgence bin and spray it back for 5 hours. The spray liquid used in the moisture restoration bin is obtained by mixing the King Kong rattan juice collected by the backflow spraying equipment and tap water according to the weight and number ratio of 1:10, The relative humidity in the damp chamber is 100%;

[0045] (5) Send the paste-like diamond rattan material after moisture regaining into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com