Abrasive block hot press forming binding system

A technology of hot pressing and grinding, which is used in transportation and packaging, metal processing equipment, etc., can solve the problems of easy decomposition of resin and poor thermal stability of grinding, so as to achieve not easy slag loss, long service life, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

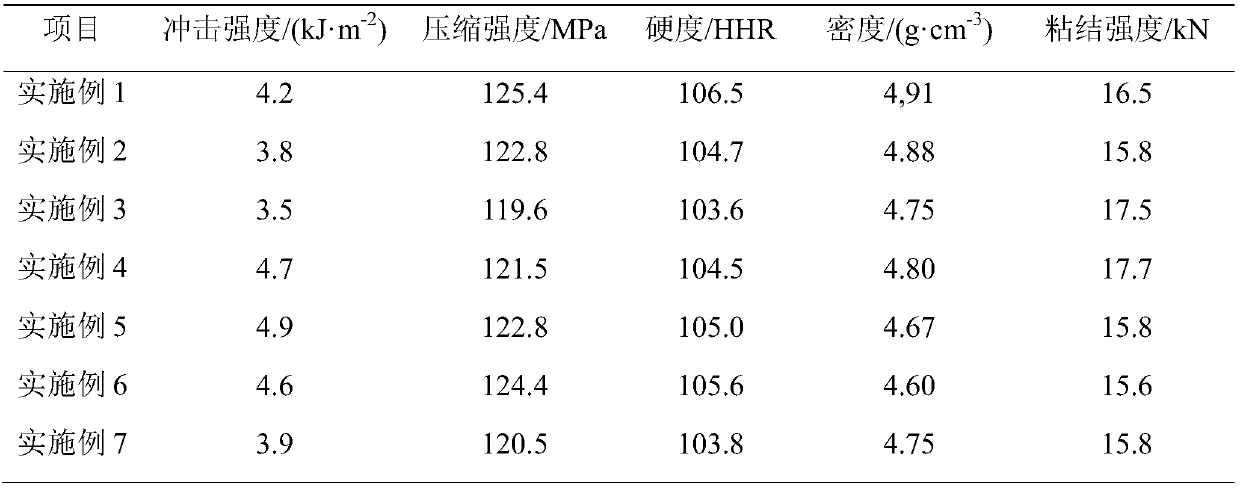

Examples

Embodiment 1

[0032] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

[0033]Metal iron powder and carbon fiber are the main raw materials, of which iron powder content is 73%, carbon fiber content is 15%, thermoplastic phenolic resin is 0.5%, thermosetting resin is 3.5%, anhydrous borax is 1%, ethylene glycol is 1%, and dimethyl carbonate is 6%. %, mixed and granulated by a rake mixer, and hot-pressed.

[0034] After forming, the sample is cut and inspected. The performance of the product is tested by the friction testing machine as follows: torque at room temperature: 8.1, torque at 300°C: 8.26, torque at 500°C: 8.20.

Embodiment 2

[0036] Metal iron powder and aramid fiber are the main raw materials, of which iron powder content is 72%, aramid fiber content is 12%, thermoplastic phenolic resin is 0.7%, thermosetting resin is 4.9%, anhydrous borax is 1.4%, ethylene glycol is 2%, carbonic acid Dimethyl fat 7%, mixed and granulated by a plow mixer, and hot-pressed.

[0037] After forming, the sample is cut and inspected, and the performance of the product is tested by the friction testing machine as follows: torque at room temperature: 8.18, torque at 300°C: 8.22, torque at 500°C: 8.19.

Embodiment 3

[0039] Metal iron powder and copper fiber are the main raw materials, of which iron powder content is 75%, aramid fiber content is 10%, thermoplastic phenolic resin is 0.7%, thermosetting resin is 4.9%, boron glass powder is 1.4%, ethylene glycol is 1.5%, mixed with two Dimethyl dibasic acid 6.5%, kneaded and granulated by plow-rake mixer, and hot-pressed.

[0040] After forming, the sample is cut and inspected. The performance of the product is tested by the friction testing machine as follows: torque at room temperature: 8.23, torque at 300°C: 8.25, torque at 500°C: 8.47.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com