Microparticle Manufacturing Method

A manufacturing method and particle technology, applied in separation methods, chemical instruments and methods, crystallization regulation/control, etc., can solve problems such as reduction in processing flow, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

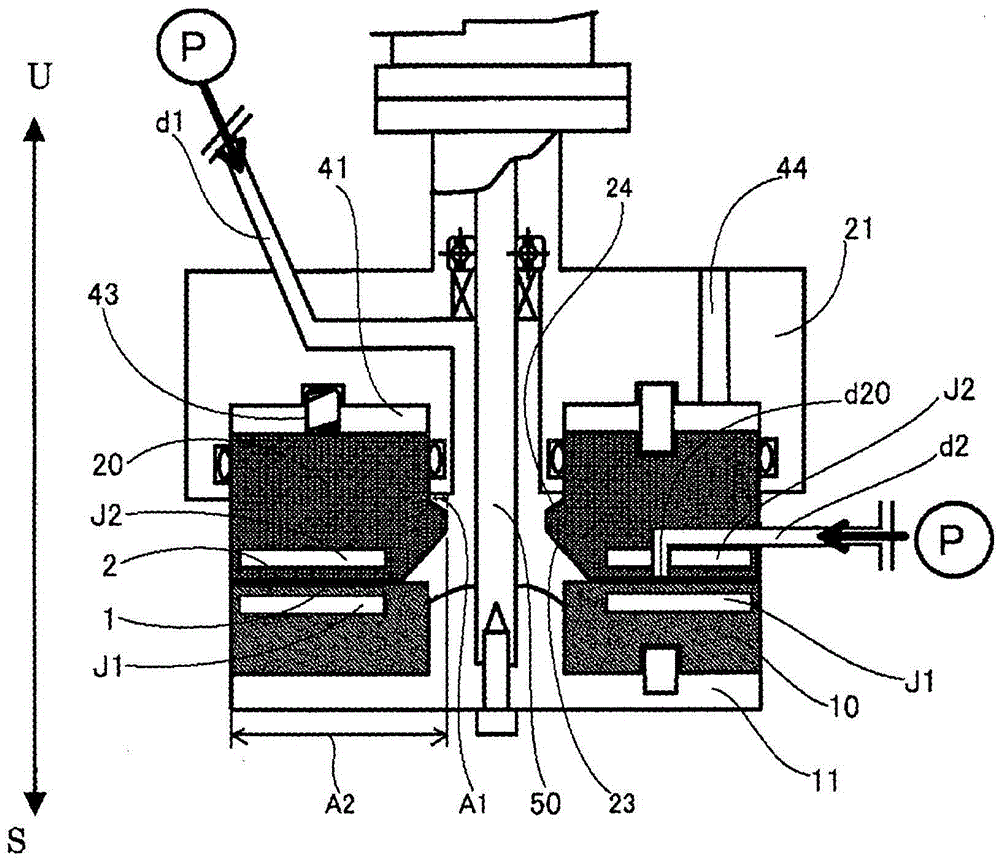

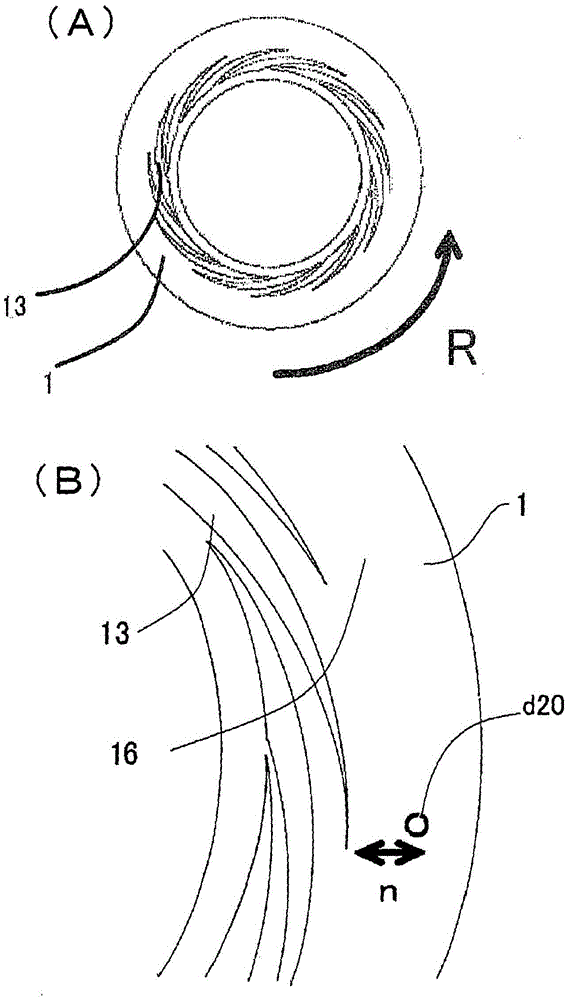

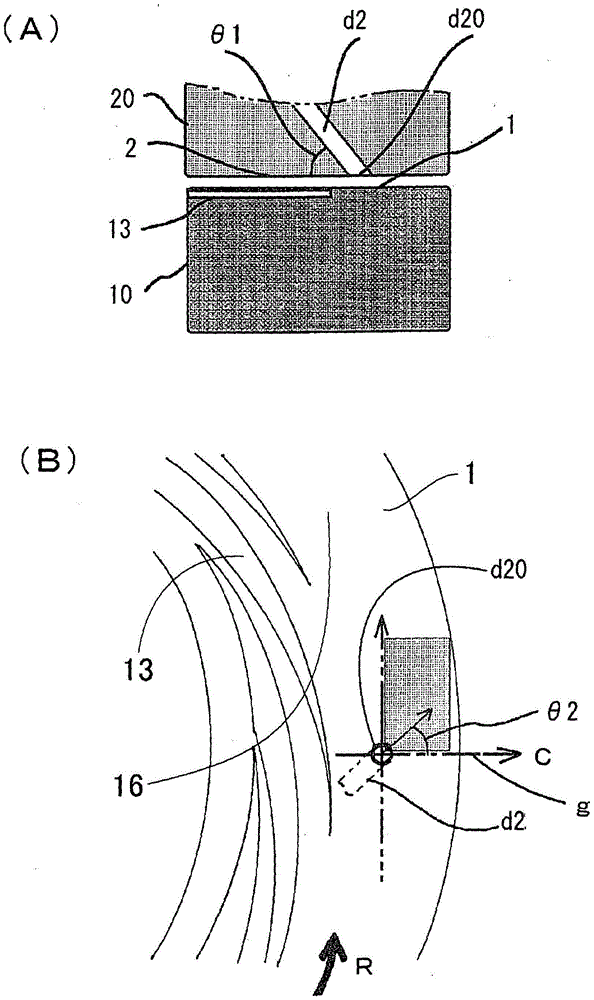

Method used

Image

Examples

Embodiment 1

[0147]As Example 1, the discharge liquid of the seed crystal particles containing nickel particles discharged from between the processing surfaces 1 and 2 was collected in one container for 20 seconds under the above-mentioned conditions. During the recovery, it was confirmed that the discharge liquid changed from a yellow-green turbid state to a black state, and the recovery was carried out for 20 seconds. After the recovery was completed for about 20 seconds, the change in the color of the discharge liquid disappeared visually. The temperature of the discharge liquid at this time was 95°C. In order to collect the fine nickel particles, the discharge liquid was allowed to stand still at room temperature. Thereafter, nickel fine particles were precipitated, and the supernatant was removed, followed by washing with pure water three times, and drying under atmospheric pressure at 25°C. As a result of XRD measurement of the dried nickel microparticle powder, it was confirmed tha...

Embodiment 2

[0151] As Example 2, as in Example 1, the effluent discharged from between the treatment surfaces 1 and 2 in Example 1 was collected in one container for 20 minutes. During the recovery, it was confirmed that the effluent changed from a yellow-green turbid state to black, and about 40 seconds after the start of recovery, the change in the color of the effluent disappeared visually, and the temperature of the effluent at this time was 95°C. Nickel fine particles were recovered by the same operation as in Example 1, and XRD measurement and SEM observation were performed. As a result of the XRD measurement, it was confirmed that homogeneous nickel without impurities was produced. Figure 6 A SEM photograph of the nickel fine particles obtained in Example 2 is shown. From Figure 5 , 6 Confirmation: Compared with Example 1, inhomogeneous microparticles with inconsistent particle diameter uniformity were produced.

Embodiment 3

[0155] As Example 3, such as Figure 4 As shown in the fluid treatment device of , a vessel 61 connected to a tubular container 62 for collecting the discharge liquid is provided. In addition, the diameter of the tubular container and the length of the tubular container are set such that the residence time of the discharge liquid in the tubular container 62 is 20 seconds or more. In addition, the tubular container 62 is immersed in an oil bath 65 . Under the same conditions as in Example 1, the nickel solution and the reducing agent solution are mixed in the thin film fluid produced between the faces 1 and 2, and the fluid containing the seed crystal particles of the nickel particles is used as the discharge liquid from the face 1 , 2 discharges, the discharge liquid is continuously introduced into the tubular container 62 from the inlet 63 of the tubular container, and discharged from the outlet 64 of the tubular container. The discharge liquid is continuously discharged wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com