Stereolithography method for producing a three-dimensional object, comprising a movement according to which a supporting surface for said object intermittently approaches the bottom of a container, and stereolithography machine using said method

A technology of stereolithography and supporting surfaces, applied in 3D object support structures, processing data acquisition/processing, manufacturing tools, etc., can solve the problems of container wear, container damage, inconvenient replacement costs, etc., to reduce processing time and reduce continuous the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

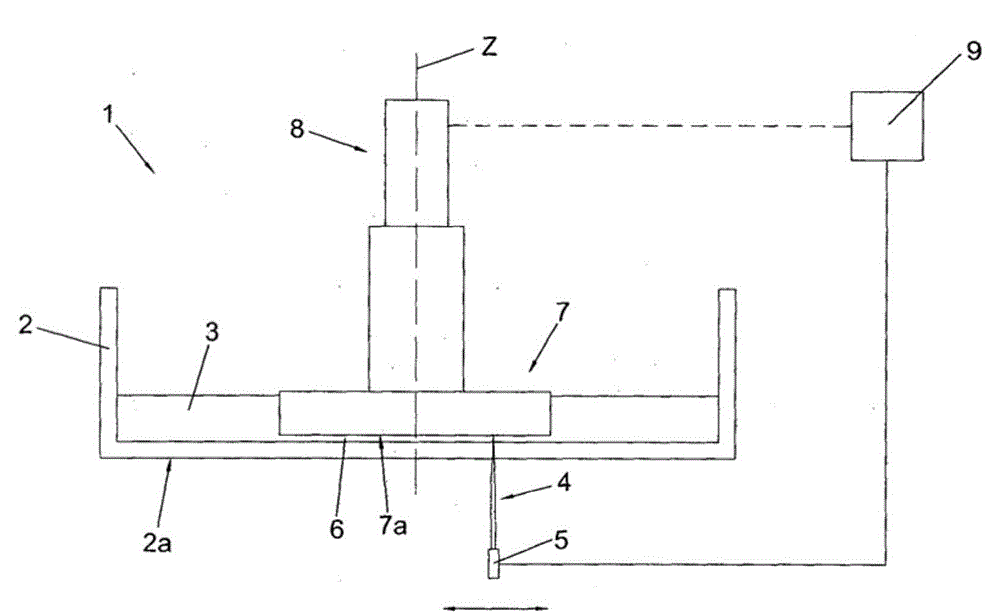

[0044] refer to figure 1 The method for producing a three-dimensional object which is the subject of the invention is described in a stereolithography machine denoted as a whole by 1 .

[0045] The stereolithography machine 1 described above comprises a container 2 for containing a liquid substance 3 suitable to be solidified by exposure to predetermined radiation 4 .

[0046] The machine 1 also comprises means 5 suitable for emitting said predetermined radiation 4 capable of selectively irradiating a layer 6 of liquid substance 3 having a predetermined thickness and arranged adjacent to the bottom 2a of the container 2 .

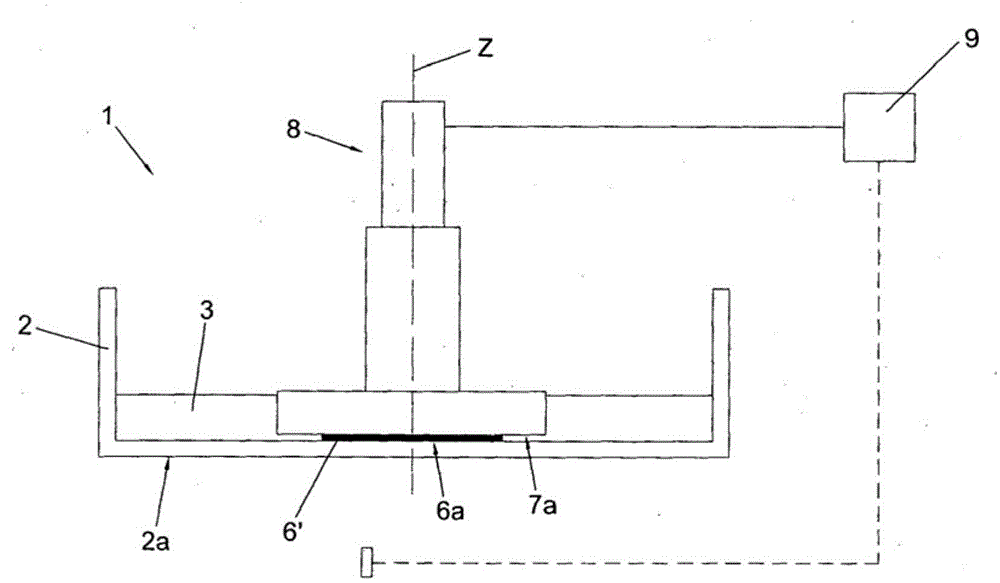

[0047] Irradiation of the liquid layer 6 results in the formation of a corresponding solidified layer 6' of the object, as figure 2 shown schematically in .

[0048] Preferably, but not necessarily, said predetermined radiation 4 is a laser beam passed through the above-mentioned radiation device 5 , which is selectively directed at an area corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com