Adhesive tape processing device

A processing equipment and tape technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of unstable production process, poor dimensional stability of tape processing, danger, etc., to avoid jumping, improve the pass rate, The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention are described below by specific embodiments, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

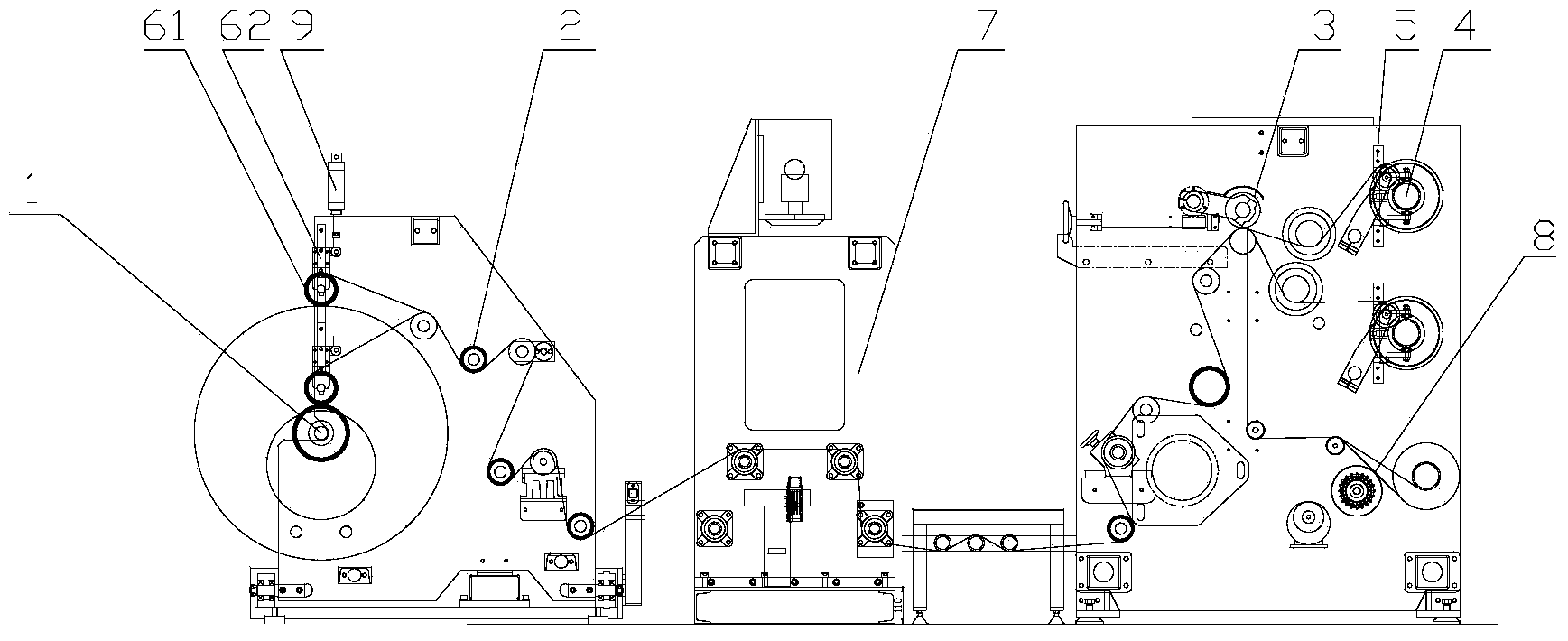

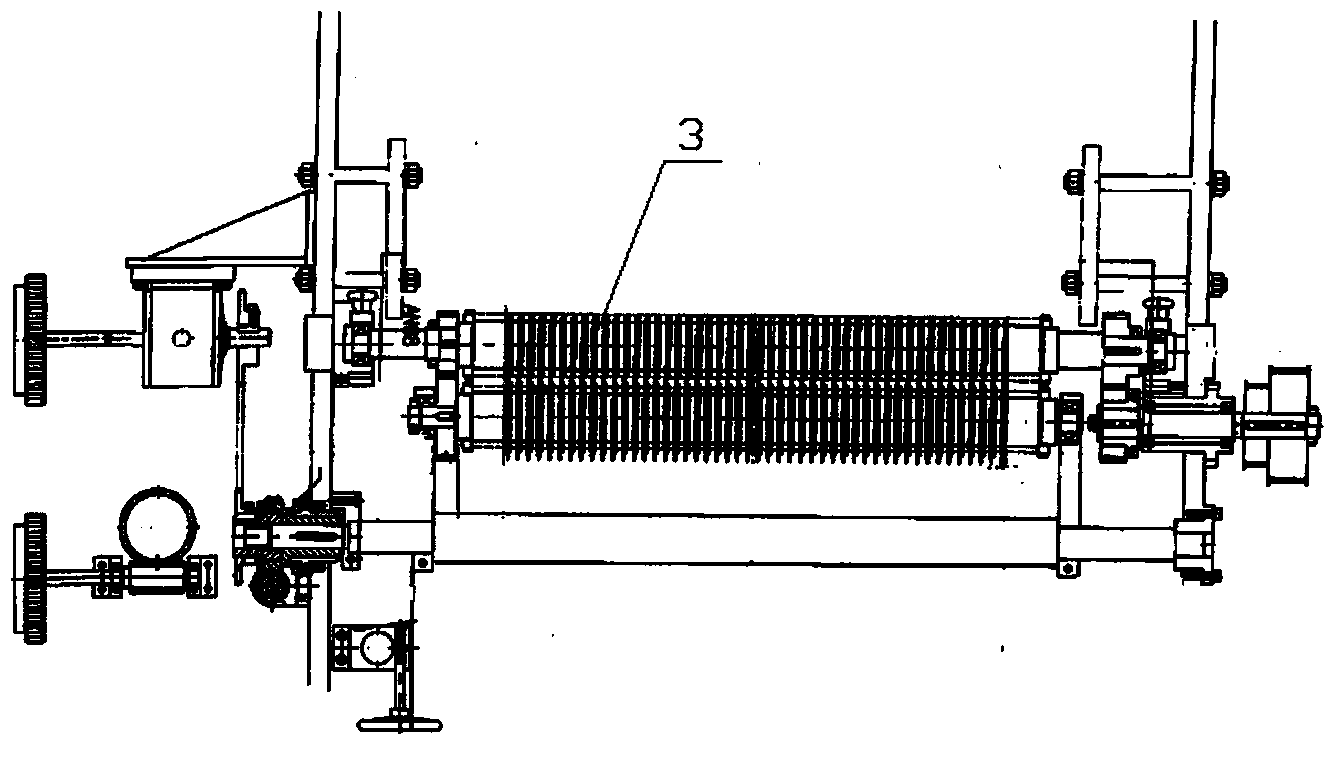

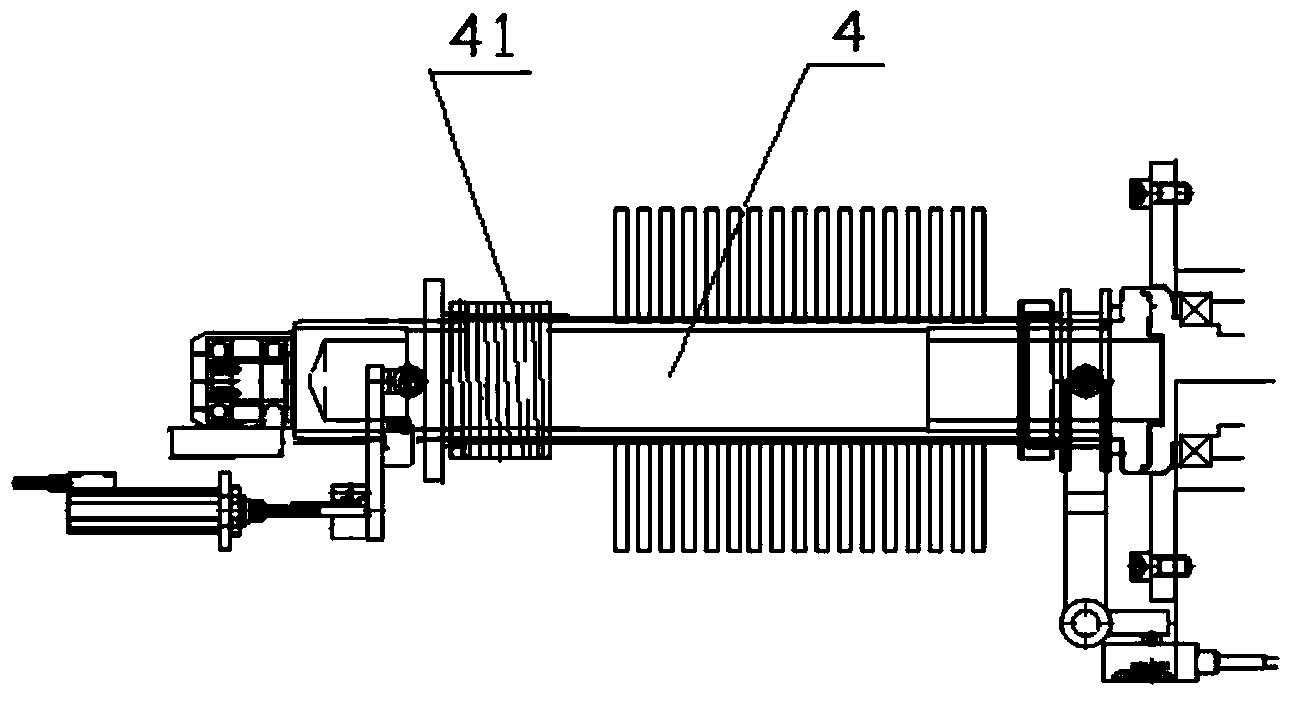

[0049] like figure 1 As shown, the present invention provides an adhesive tape processing equipment, including a fixed shaft 1 of an unwinding core, a conveying system, a slitting system, a rewinding system and a rewinding protection system.

[0050] The fixed shaft 1 of the unwinding core is a rotating shaft, and the two ends of the rotating shaft are provided with fixed clamping devices for fixing the tape to be processed. The tape to be processed described in this specification is a wider tape that has not been cut. . When the tape is processed, the core sleeve of the tape to be processed is combined and fixed on the fixed shaft 1 of the unwinding core. When the fixed shaft 1 of the unwinding core rotates, the tape to be proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com