Connecting device of solvent dripping box and double-partition pump

A connecting device and a double-compartment pump technology, applied in the field of packaging materials, can solve the problems of human health hazards, large amount of glue applied, waste of glue, etc., and achieve the effects of avoiding a large amount of volatilization, low cost, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

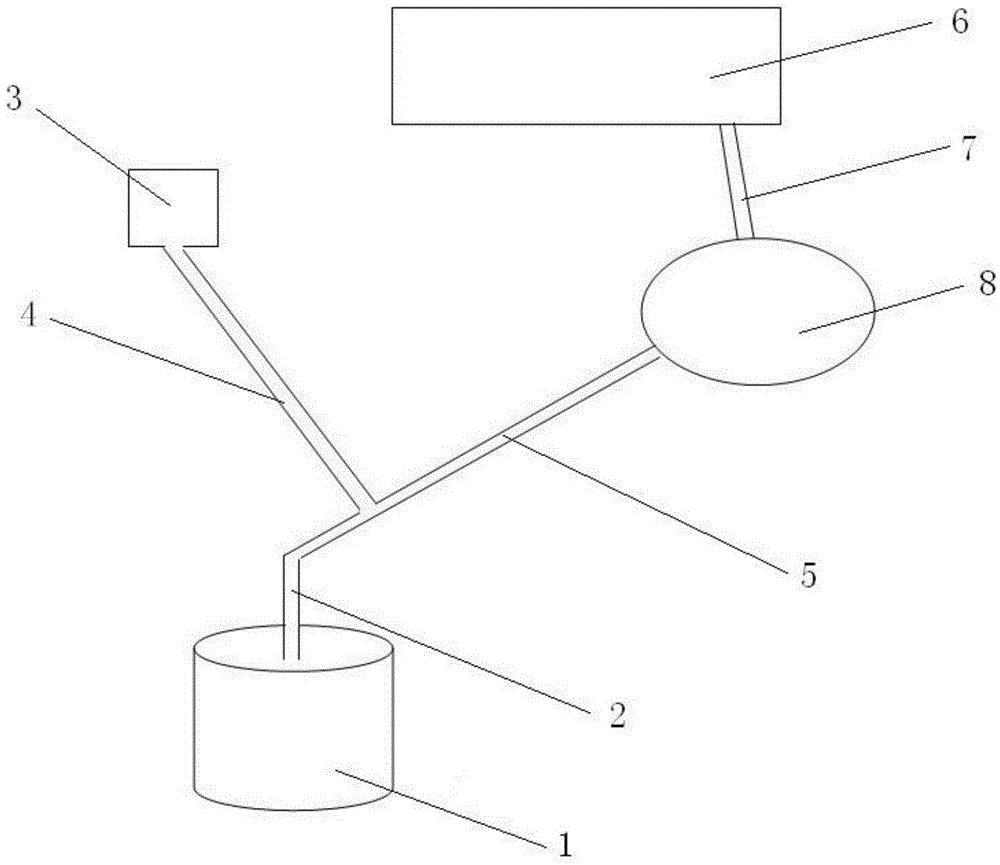

[0011] Such as figure 1 As shown, the present invention mainly comprises glue barrel 1, dripping solvent box 3, glue box 6 and double compartment pump 8, is connected on the glue barrel 1 and takes glue hose 2, and takes glue hose 2 other ends and connects mixing pipe 5 by tee joint. The solvent drop box 3 is connected with a solvent pipe 4, and the solvent pipe 4 is connected with a mixing pipe 5 through a three-way joint.

[0012] The mixing tube 5 is connected with a double compartment pump 8, the double compartment pump 8 is connected with a rubber delivery hose 7, and the other end of the rubber delivery hose 7 is connected with a glue box 6.

[0013] A valve is provided on the solvent pipe 4, and the flow of the solvent is controlled through the valve.

[0014] The working principle of the present invention is: when working, glue enters the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com