Special extending and unfolding device for carrying out oil membrane separation on crystalline dextrose saccharification liquid

A technology of crystallizing glucose and saccharification solution, which is applied in the field of glucose production, can solve the problems of reducing the speed of rolling curtain deployment and low operating efficiency, and achieve the effects of improving stability, convenient operation, and improving deployment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

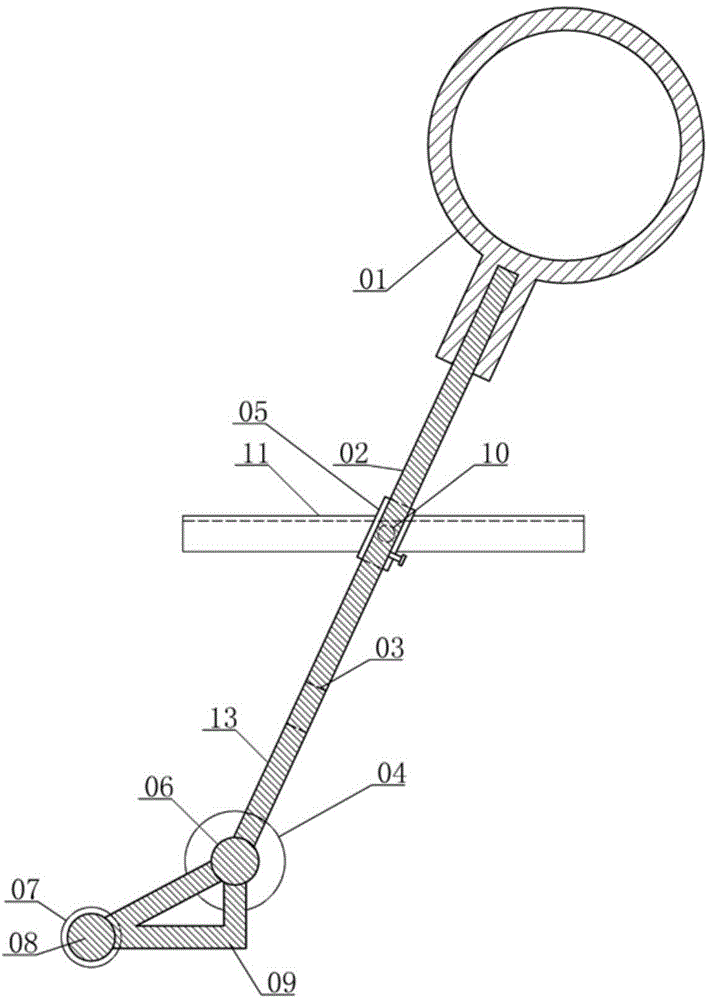

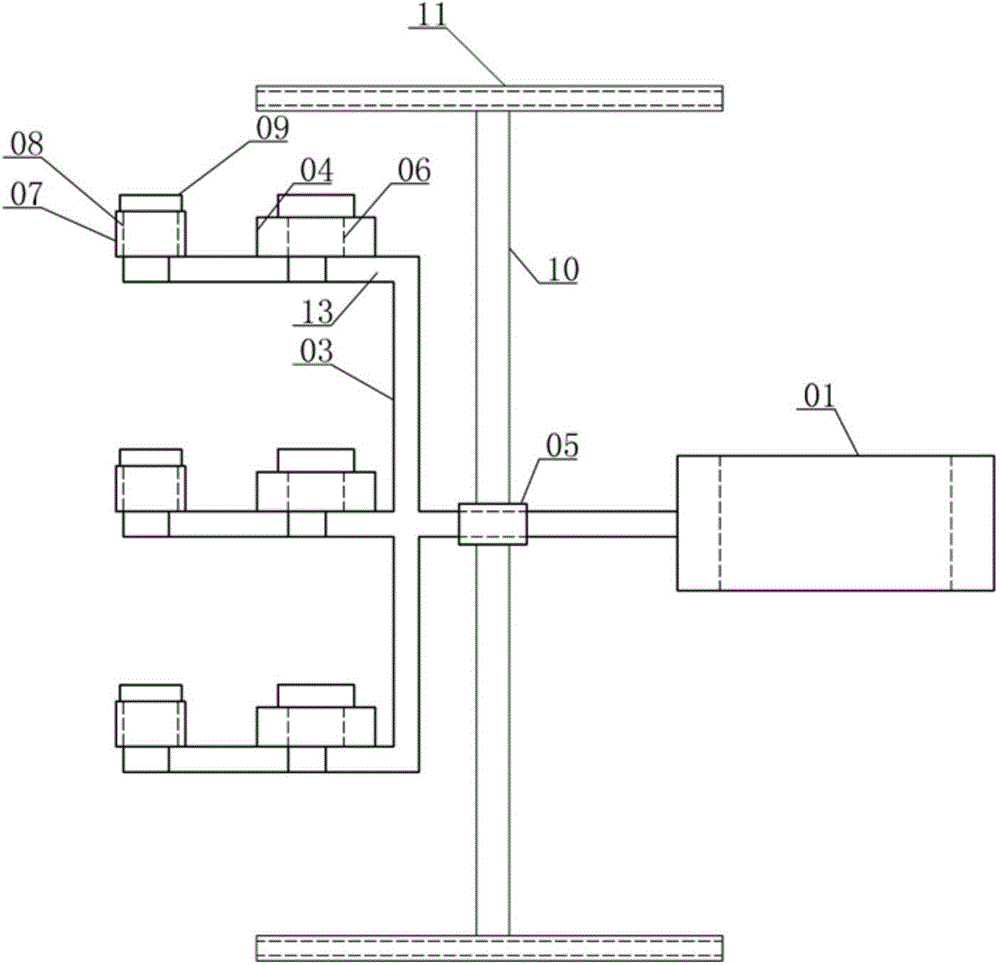

[0020] Special pusher for oil film separation of crystalline glucose saccharified liquid, consisting of grip ring 01, handle 02, beam 03, limit wheel 04, positioning sleeve 05, limit wheel shaft 06, push wheel 07, push wheel shaft 08, tripod 09, cross bar 10 , Guide box 11, fastening knob 12 and handle 13 constitute.

[0021] The top end of the handle 02 is an annular grip ring 01 screwed on the handle 02 .

[0022] The middle part of the handle 02 has a cylindrical positioning sleeve 05 which is sleeved on the handle 02. There is a screw hole on the side wall of the positioning sleeve 05, and the screw rod of the fastening knob 12 passes through the screw hole. Also be welded with two cross bars 10 that are arranged horizontally on the outer sidewall of positioning sleeve 05, the end of each cross bar 10 has a bar-shaped guide box 11, each guide box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com