Elastic PET composite fiber and method for preparing elastic PET composite fiber

A composite elastic fiber, composite fiber technology, applied in fiber processing, conjugated synthetic polymer artificial filament, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

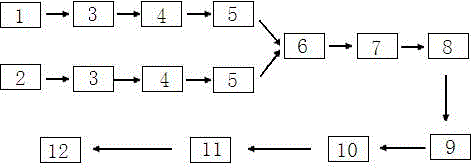

Method used

Image

Examples

Embodiment 1

[0052] Types of PET slices Viscosity (dL / g) parts by mass low viscosity PET 0.47 30 High viscosity PET 0.82 70

[0053] Table 5 Slice type and composition ratio table.

[0054] Zone 1 temperature ℃ Second zone temperature ℃ Three zone temperature ℃ Four zone temperature ℃ low viscosity components 266 268 270 269 high viscosity components 279 288 288 286

[0055] Table 6 Temperature control table for each area.

Embodiment 2

[0057] Types of PET slices Viscosity (dL / g) parts by mass low viscosity PET 0.47 50 High viscosity PET 0.82 50

[0058] Table 7 Types of slices and composition ratio table.

[0059] Zone 1 temperature ℃ Second zone temperature ℃ Three zone temperature ℃ Four zone temperature ℃ low viscosity components 266 268 269 268 high viscosity components 279 288 286 284

[0060] Table 8 Temperature control table for each area.

Embodiment 3

[0062] Types of PET slices Viscosity (dL / g) parts by mass low viscosity PET 0.52 50 High viscosity PET 0.89 50

[0063] Table 9 Slice type and component ratio table.

[0064] Zone 1 temperature ℃ Second zone temperature ℃ Three zone temperature ℃ Four zone temperature ℃ low viscosity components 268 270 271 270 high viscosity components 281 290 289 288

[0065] Table 10 Temperature control table for each area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com