An explosive combination device for directional cutting blasting in open-pit mines

A technology of cutting blasting and combination device, applied in blasting and other directions, can solve the problems of difficult positioning of charge packs, low efficiency, and difficulty in deep-hole charging, and achieve the effects of simple and convenient charging, improving construction efficiency, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further describe the present invention, an explosive combination device for directional cutting blasting in open-pit mines of the present invention will be further described below in conjunction with the accompanying drawings and examples.

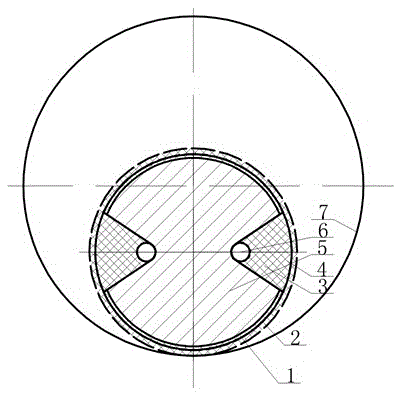

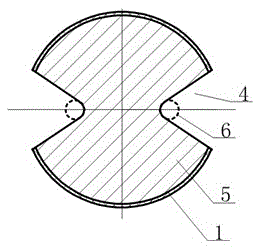

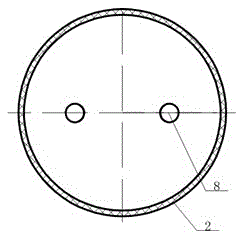

[0023] Depend on figure 1 Shown is a schematic diagram of the cross-sectional structure of an explosive combination device used for directional cutting blasting in open-pit mines of the present invention and combined with figure 2 , Figure 5 It can be seen that the explosive combination device is placed in the inclined cutting hole 7 of the open-pit mine slope, and it is composed of several sections of explosive devices connected in series through detonating cords 6, and each meter of detonating cords 6 is connected in series with 2 to 4 sections of explosive devices. Section explosive device contains charge tube 1, the explosive 5 that is contained in charge tube 1. Both sides of the charge tube 1 are symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com