Loading device for automobile hub bearing periodicity dynamic tester

A dynamic test and wheel bearing technology, applied in mechanical bearing testing and other directions, can solve the problems of low loading accuracy, vibration of loading oil cylinder, restricting the improvement and perfection of automobile wheel bearing structure, etc., and achieve the effect of reducing test cost and improving test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described with reference to the drawings and specific embodiments, but it should be noted that the present invention is not limited to the following embodiments.

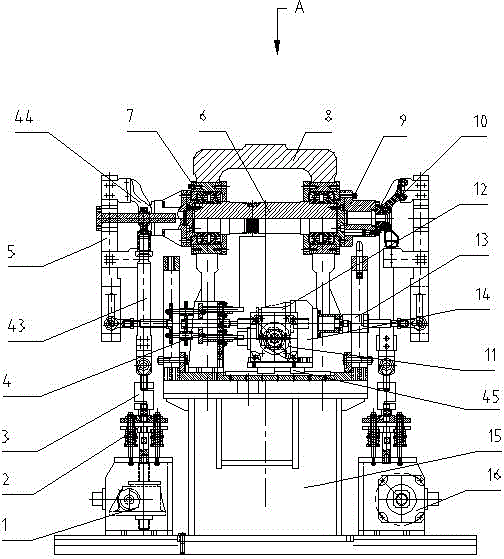

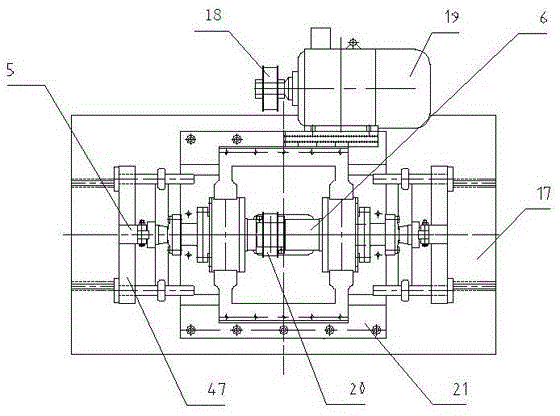

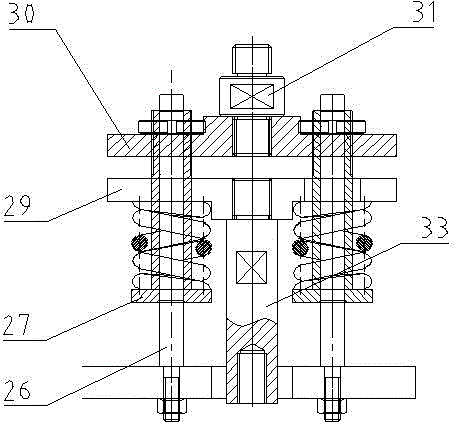

[0018] Such as figure 1 , figure 2Shown, a kind of loading device of the periodic dynamic testing machine of automobile hub bearing, described testing machine comprises testing machine main shaft 6, the drive transmission mechanism that drives testing machine main shaft to rotate, axial loading mechanism and radial loading mechanism; Also Comprising a test system and a control system; the drive transmission mechanism used to drive the main shaft of the testing machine to rotate adopts a prior art structure, including a drive motor 19, a driving pulley 18 and a driven pulley 20; the driving pulley 18 is connected to the The output end of described driving motor 19; Described driven pulley 20 is fixed on the middle part of testing machine main shaft; Described driven pulley is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com