Operating mechanism and operating method of three-station mutual prevention and interlocking structure

An operating mechanism, three-station technology, applied in air switch parts, electrical components, electrical switches, etc., can solve the problems of high manufacturing and maintenance costs, short service life, inconvenient assembly, etc., and achieve long service life, High consistency and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

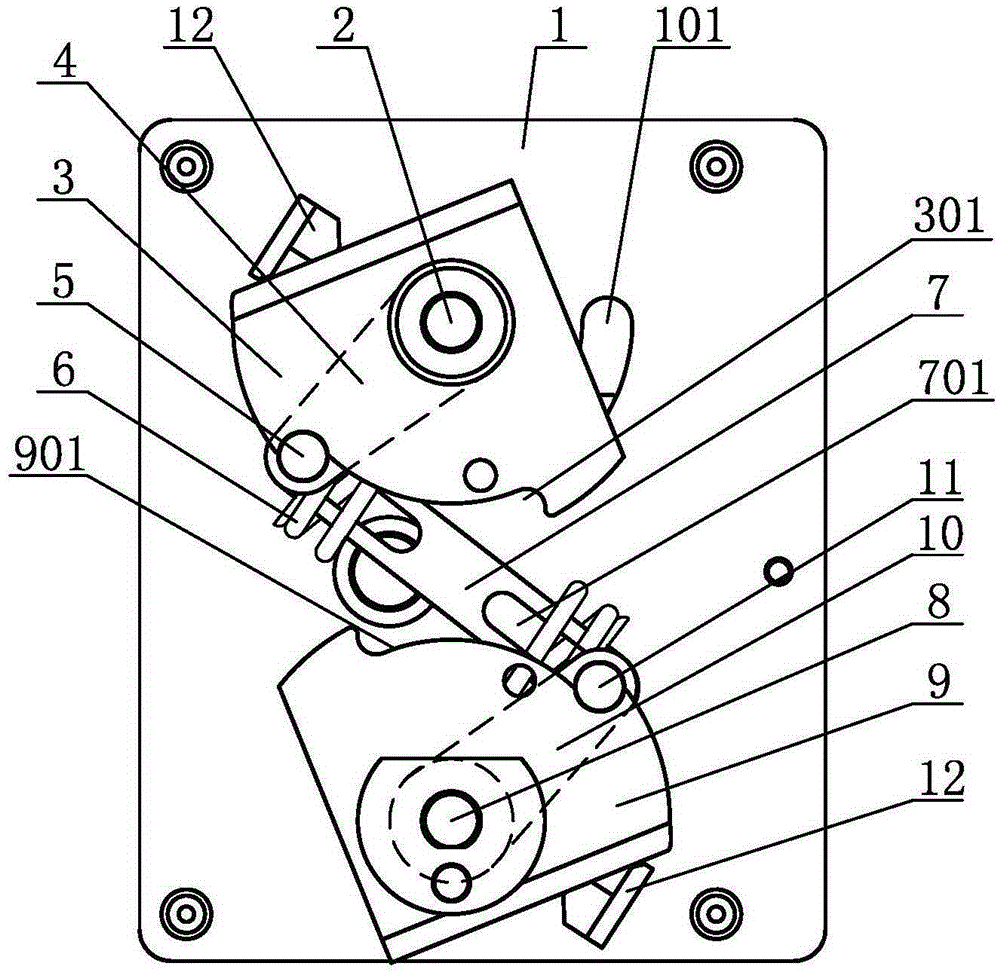

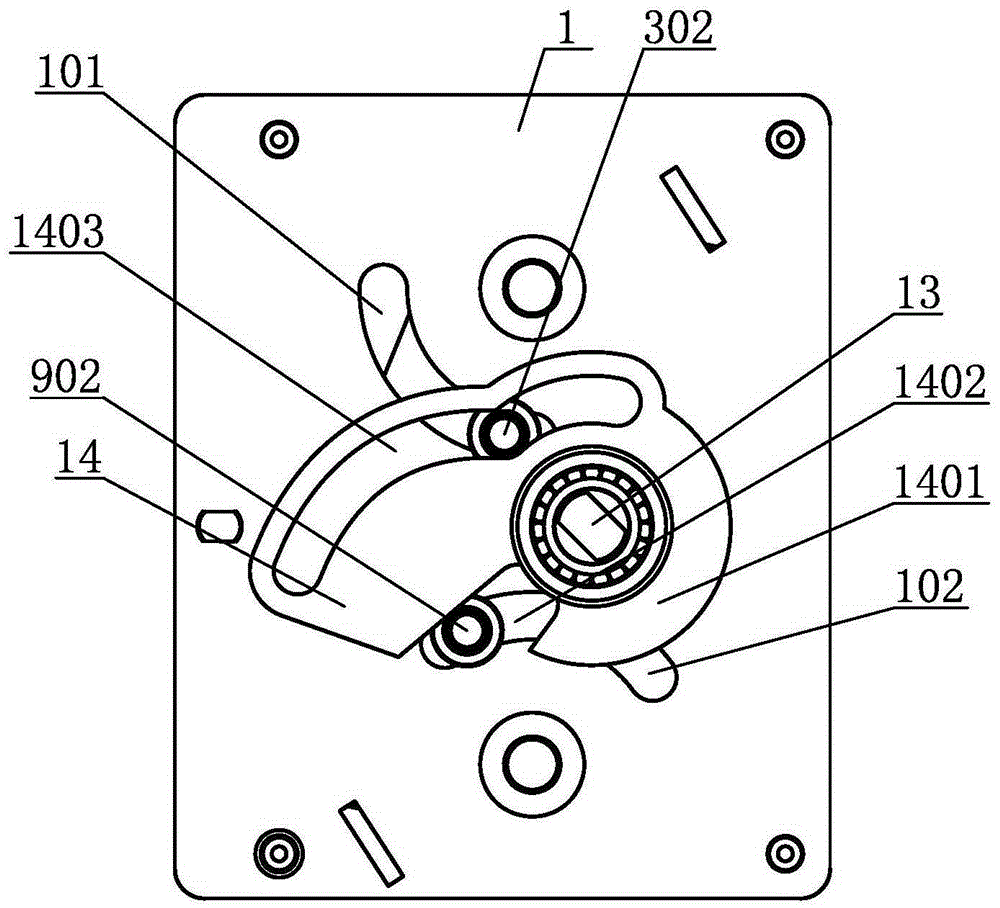

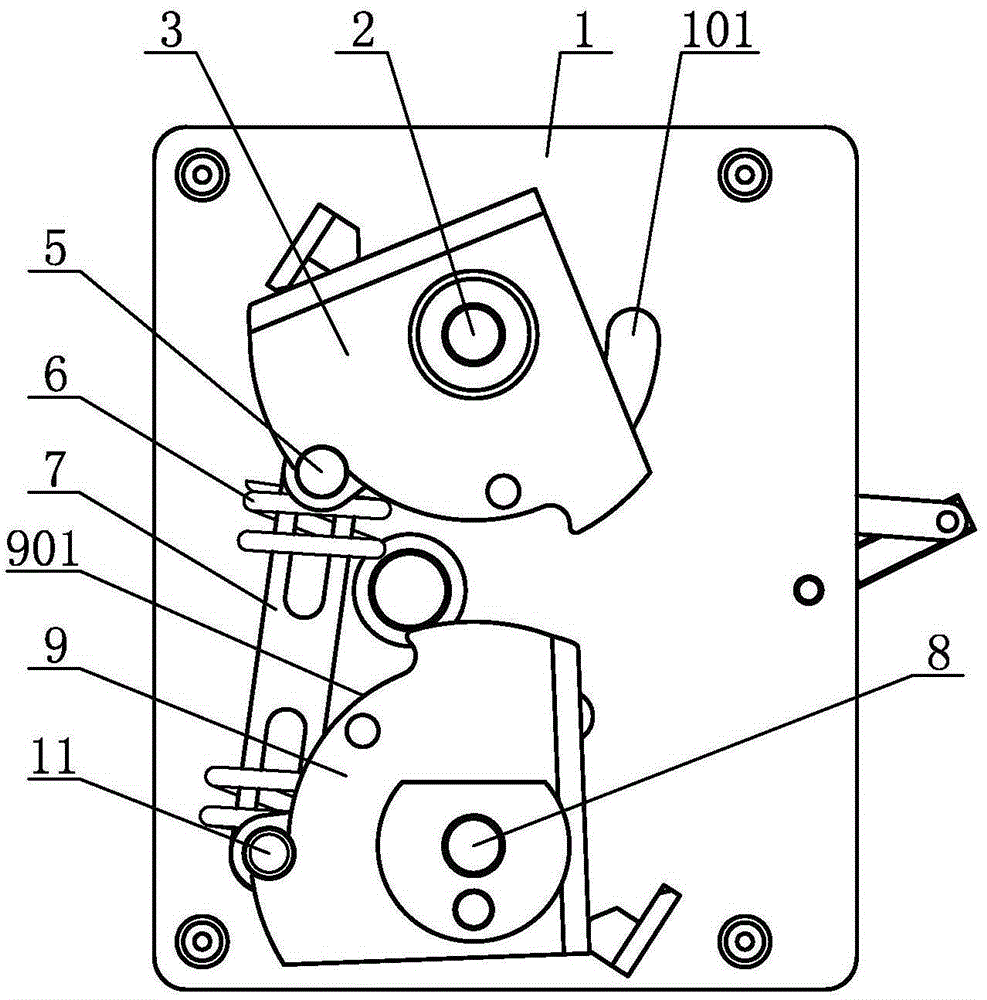

[0017] Now in conjunction with accompanying drawing, the present invention will be further described.

[0018] Such as Figure 1-6 As shown, the operating mechanism of the three-station mutual prevention and interlocking structure is installed on the mounting plate 1, which includes a closing operating part and a grounding operating part. The brake operating shaft is movably connected to the closing lever 3 which rotates relatively, and is located inside the closing lever and is fixedly connected to the closing linkage lever 4 which rotates synchronously with the closing operating axis. The grounding operation part includes the grounding operation shaft 8, The operating shaft is movably connected to the grounding crank arm 9 which is relatively rotating, and is located in the grounding crank arm and is fixedly connected to the grounding linkage crank arm 20 which is synchronously rotated by the grounding operating shaft. A limit stopper 12 is provided to limit the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com