Method and device for collection of waste lithium ion battery electrolyte solution

A lithium-ion battery and collection device technology, which is applied in the field of collecting waste lithium-ion battery electrolyte by the device used in implementing the method, can solve the problems of high requirements for centrifuge equipment, inability to realize airtight production, and high centrifuge energy consumption. Achieve the effects of industrial reproducibility, convenient large-scale operation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

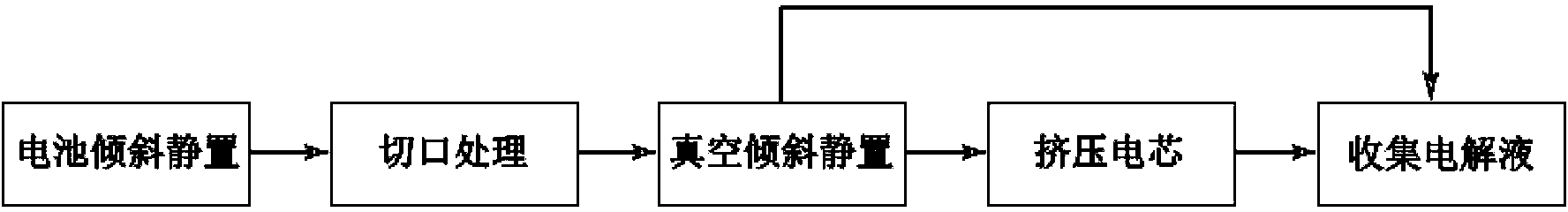

[0034] The method for collecting waste lithium ion battery electrolyte in the present embodiment comprises the following steps:

[0035] (1) Put the discharged production scrap or the waste lithium-ion battery recovered at the end of life at an angle of 30° for 30 hours, so that the electrolyte inside the battery can be gathered together for easy export;

[0036] (2) Use a milling machine to incise the top of the battery after step (1) tilting, and then place the battery incision downward at an angle of 10° in a vacuum environment with a relative pressure of -0.06MPa, keep the pressure for 10 minutes, and collect the outflowing electrolysis liquid;

[0037] (3) Take out the cell from the battery in step (2), squeeze the cell at a pressure of 6MPa and an extrusion speed of 3mm / s to a depth of 7mm, collect the electrolyte and mix it with the electrolyte in step (2). Just merge.

Embodiment 2

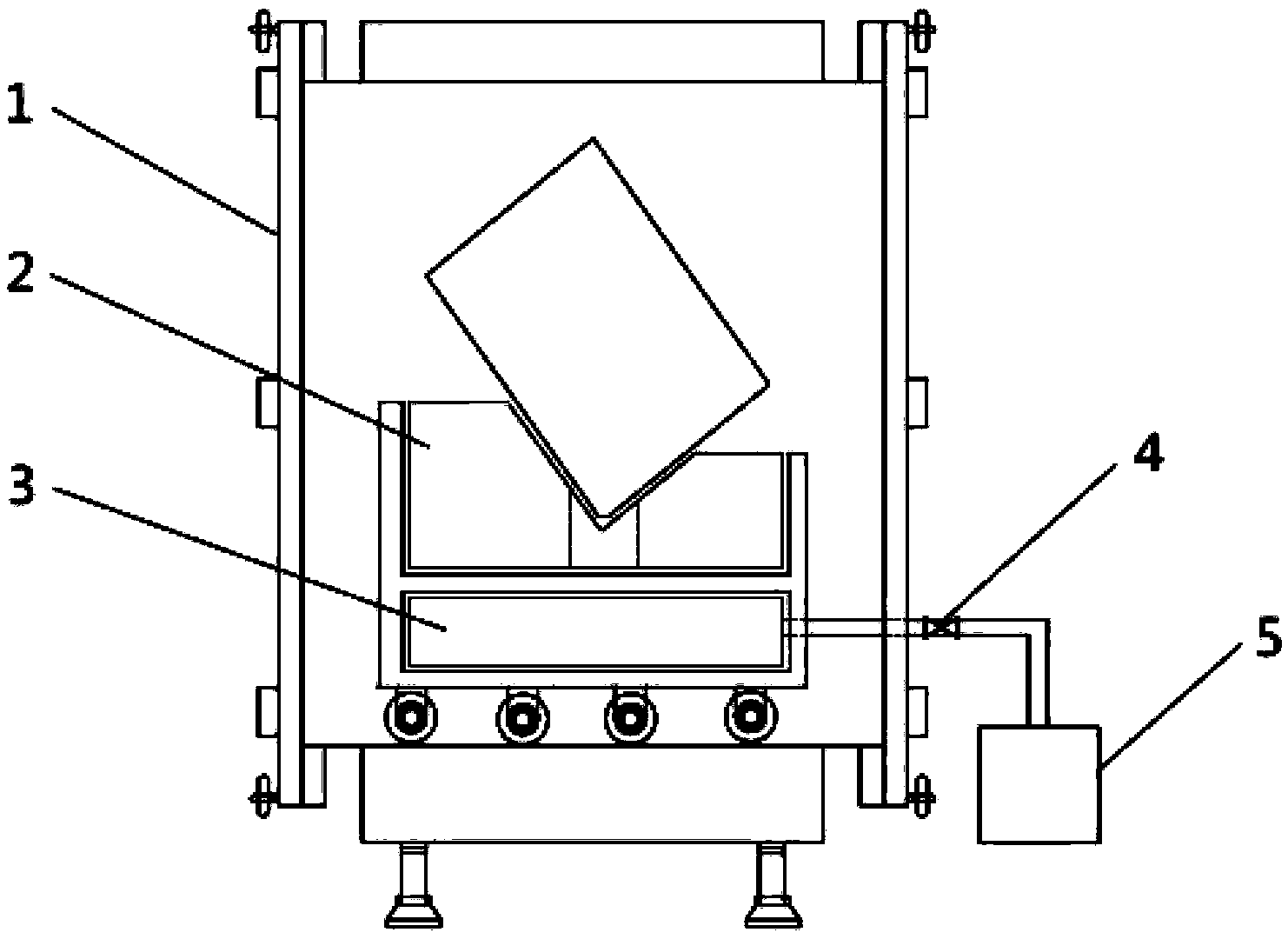

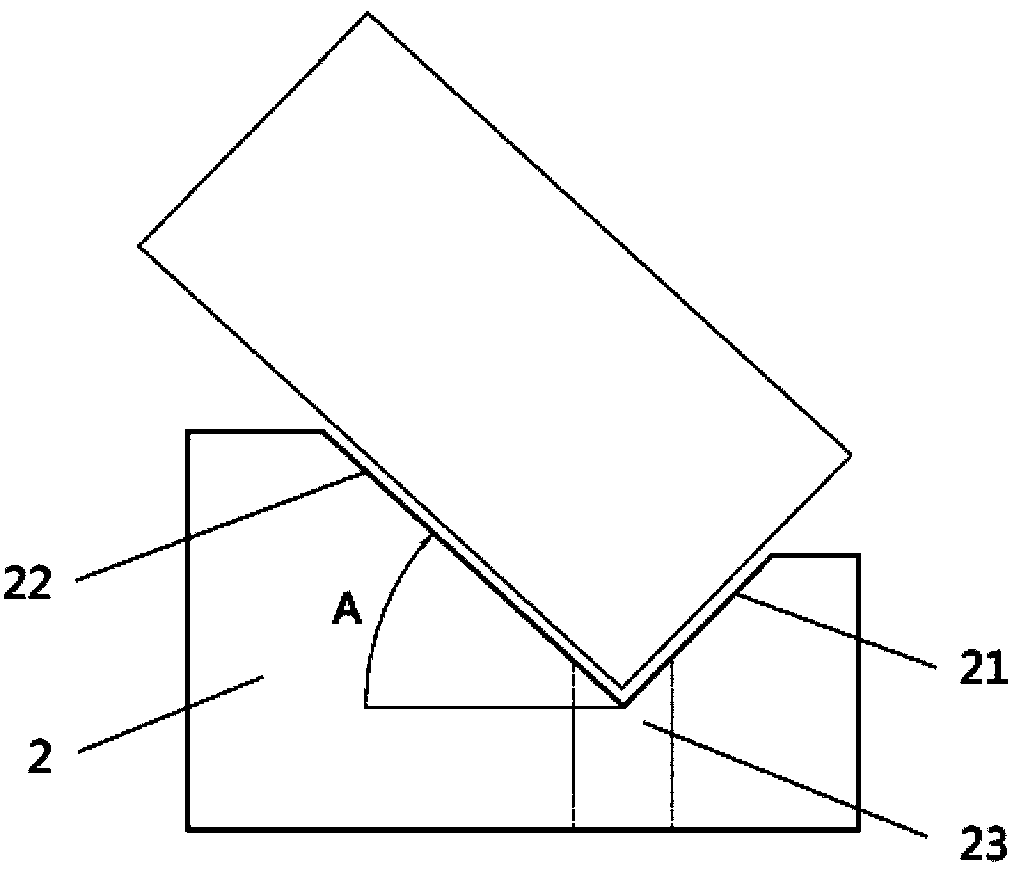

[0039] In this embodiment, the schematic diagram of the device structure for collecting the electrolyte of waste lithium-ion batteries is as follows: figure 1 As shown, it includes a vacuum box 1 and a support frame 2 that is used to place the lithium-ion battery obliquely in the vacuum box, and its structural schematic diagram is as follows figure 2 As shown, the support frame 2 has a first slope 21 and a second slope 22, the angle between the first slope 21 and the second slope 22 is 90°, the angle between the second slope 22 and the horizontal plane is A=40°, At the intersection of the first slope 21 and the second slope 22, there is a hole 23 through which the electrolyte flows. Below the supporting frame 2, there is a collection device 3 for receiving the electrolyte flowing out. The collection device 3 is a container with an opening on the top. The collection device 3 and the electrolyte transfer tank 5 arranged outside the vacuum box 1 are exported through the electrol...

Embodiment 3

[0046]The method for collecting spent lithium-ion battery electrolyte in the present embodiment comprises the following steps:

[0047] (1) Using the device for collecting the electrolyte of waste lithium-ion batteries in Example 2, place the waste lithium-ion batteries on the support frame 2 at an inclination angle of 40° and let it stand for 30 hours, so that the electrolyte inside the battery is gathered together for easy export ;

[0048] (2) Use a milling machine to cut the battery after standing still, and then place it on the support frame 2 at an inclination angle of 40°, with the cut facing the electrolyte collection device 3, and evacuate until the relative pressure in the vacuum box 1 is -0.06MPa , keep the pressure for 10 minutes, so that the electrolyte flows into the collecting device 3;

[0049] (3) First remove the battery case by mechanical method, take out the battery cell, squeeze the cell with a pressure of 1MPa, the extrusion speed is 3mm / s, and the extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap