A high-frequency connector jack and its processing method

A processing method and socket technology, which is applied in the direction of connections, parts of connection devices, contact parts, etc., can solve problems such as high-frequency performance degradation, and achieve the effects of improving service life, reducing contact resistance, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

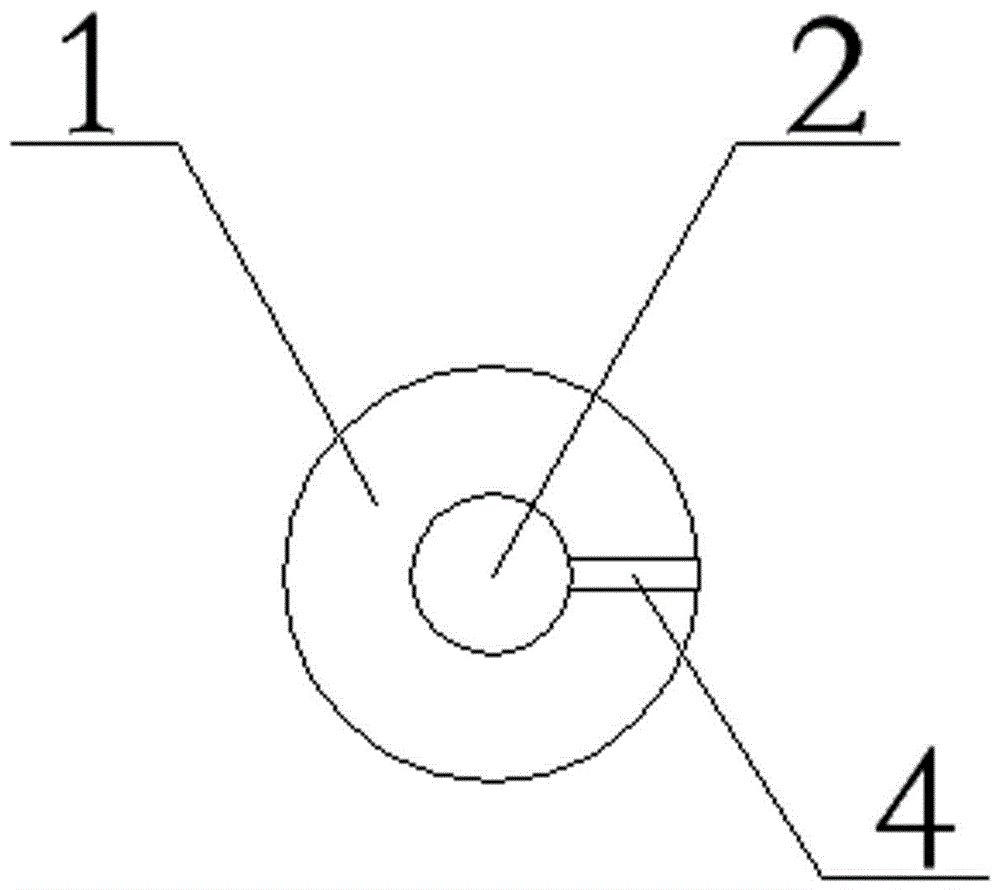

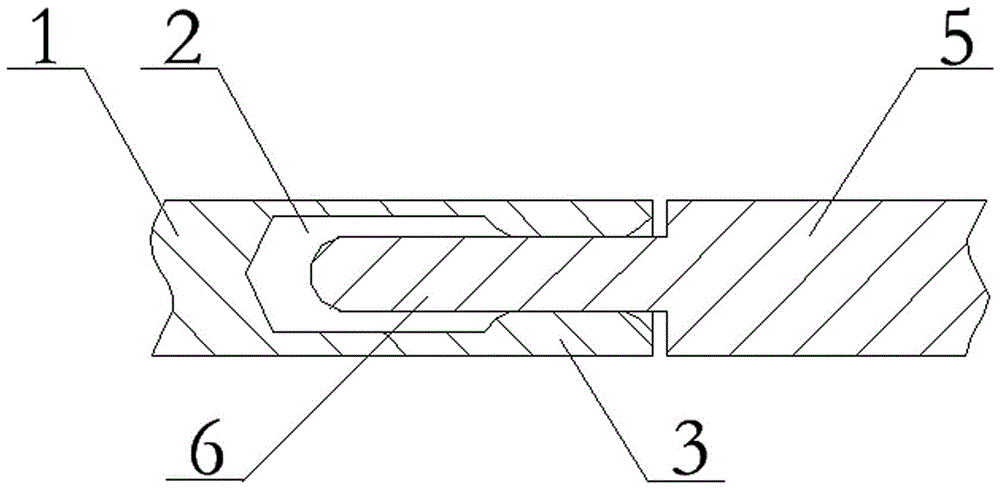

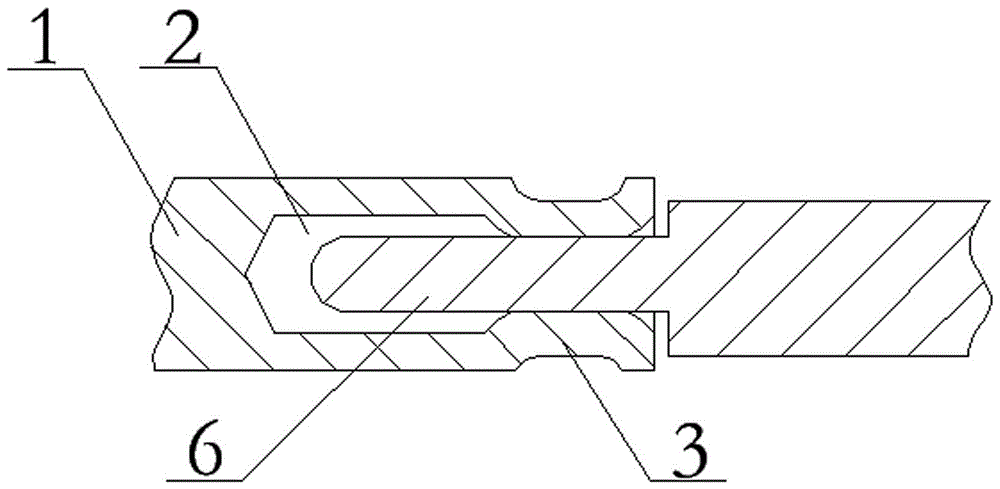

[0018] figure 1 , 2 As shown, a high-frequency connector jack includes a jack seat 1 with a jack 2, and the outer circumference of the jack seat 1 is coaxial with the outer circumference of the pin seat 5 of the pin 6 inserted into the jack 2. The same size, the inner side of the hole of the jack 2 is provided with a circle of plug-in bosses 3, and the side wall of the jack seat 1 is provided with a slot 4 that penetrates the side wall of the jack seat along the direction of the jack 2 from the inside to the outside. The groove depth is less than 85% of the socket depth.

[0019] The processing method of socket of the present invention comprises the following steps:

[0020] a. According to the final size of the socket plus the size of the mating boss and adding a machining allowance to determine the rolling diameter of the socket blank;

[0021] b. Drill the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com