3D effect testing system and method

A 3D effect and test system technology, applied in the 3D field, can solve the problems of low efficiency, low test accuracy, complicated operation steps, etc., and achieve the effect of reducing friction and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

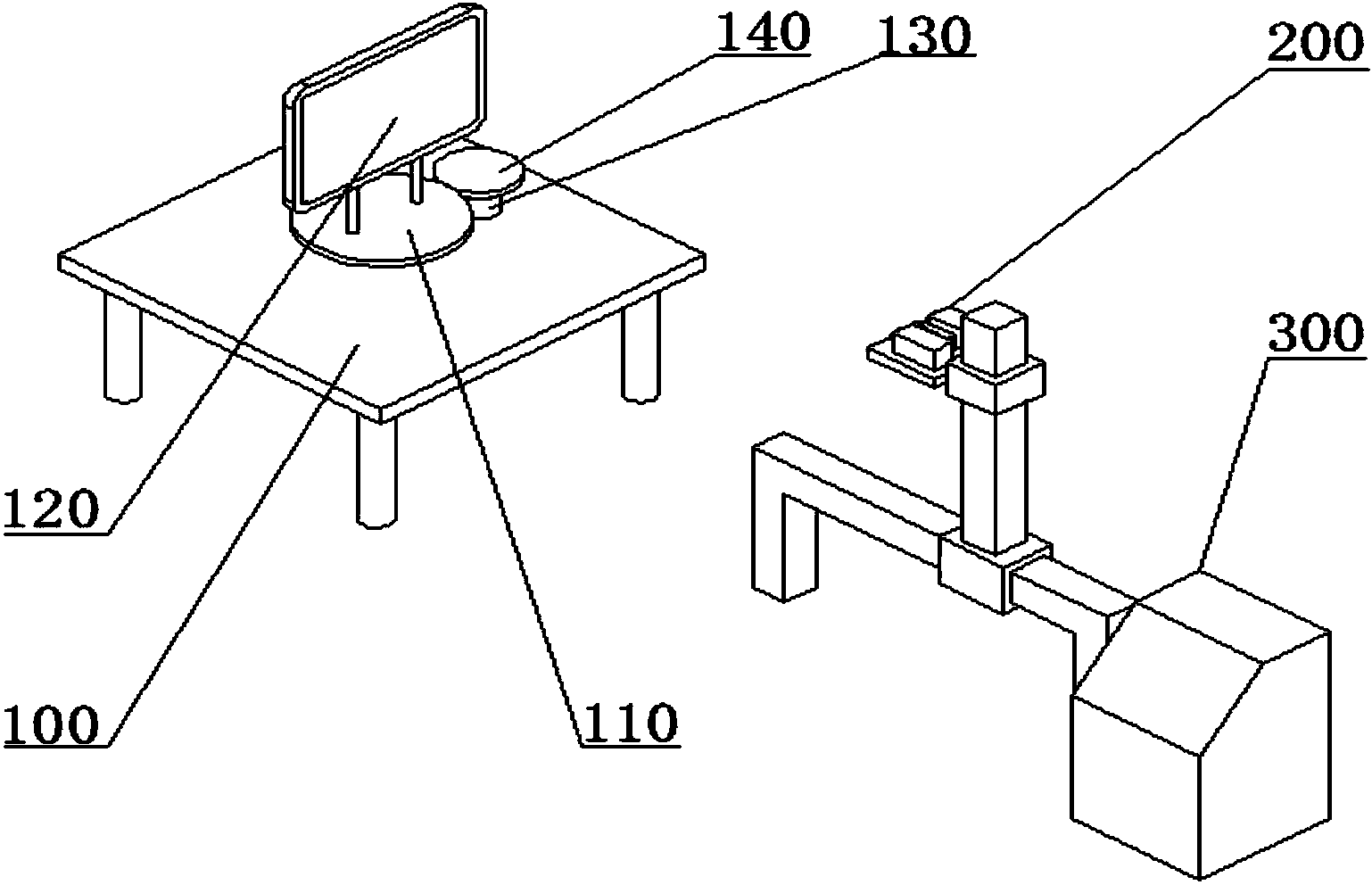

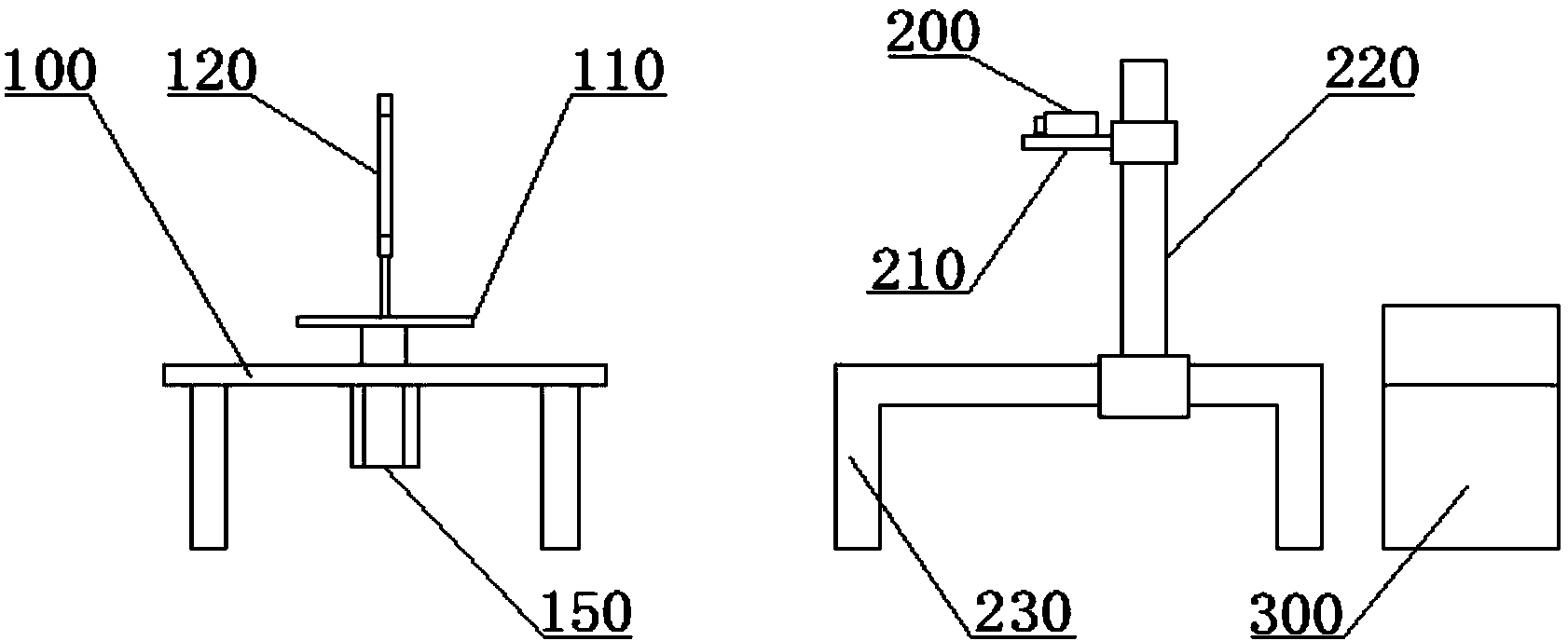

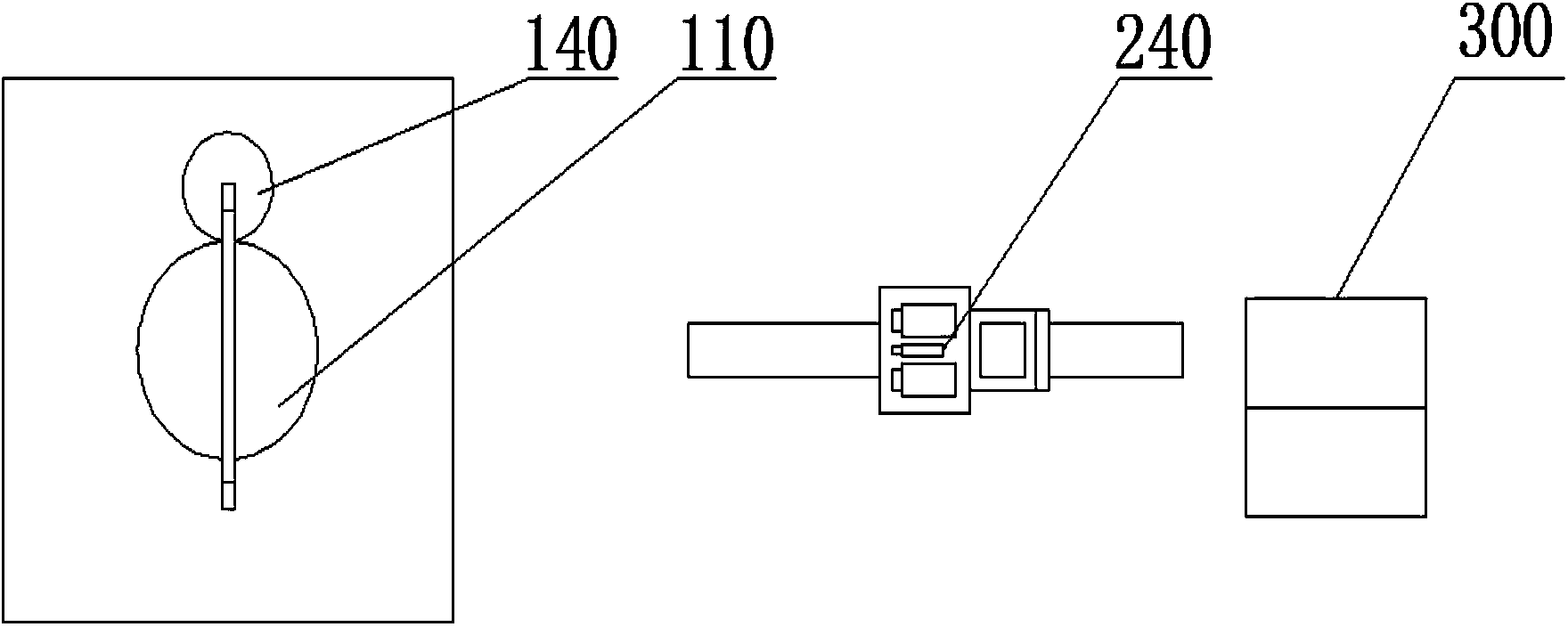

[0025] refer to Figure 1-3 , the 3D effect testing system includes a rotating platform, a testing platform and a computer 300 for controlling the cooperative work of the rotating platform and the testing platform, the rotating platform includes a base 100, the base 100 is provided with a rotating gear 110 for placing a display screen 120, and the rotating gear 110 Connected with a servo motor 150, the base 100 is also provided with an angle encoder 130, the angle encoder 130 is provided with a gear 140 meshing with the rotating gear 110, and the test platform includes an X-axis beam 230 and a Y-axis that slides with the X-axis beam 230 The beam 220 and the positioning plate 210 slidingly matched with the Y-axis beam 220, the Y-axis beam 220 and the positioning plate 210 are connected with the servo motor 150 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com