Mixing mixer

A mixer and mixing technology, which is used in mixers, mixers with rotating mixing devices, and dissolving directions, can solve problems such as poor mixing effect, dead zone of mixing, and low discharge efficiency, and avoid roller stuck. , avoid card machine, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

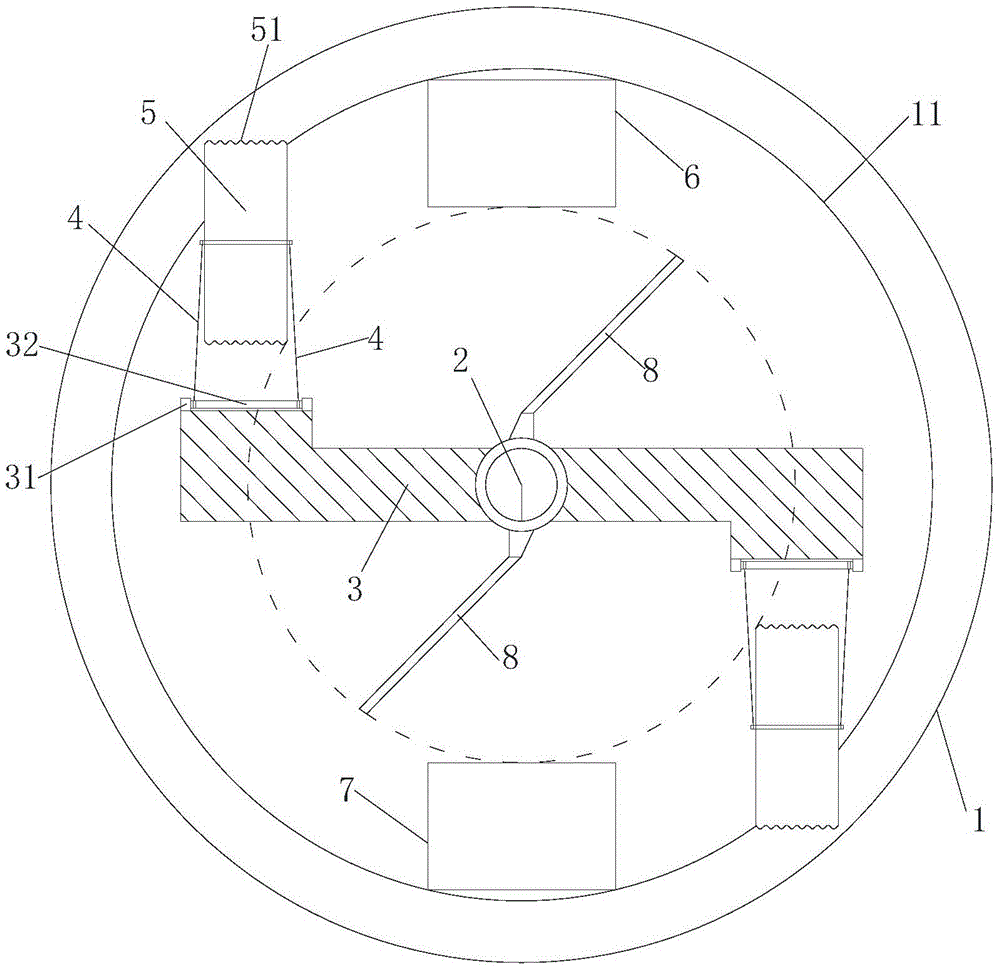

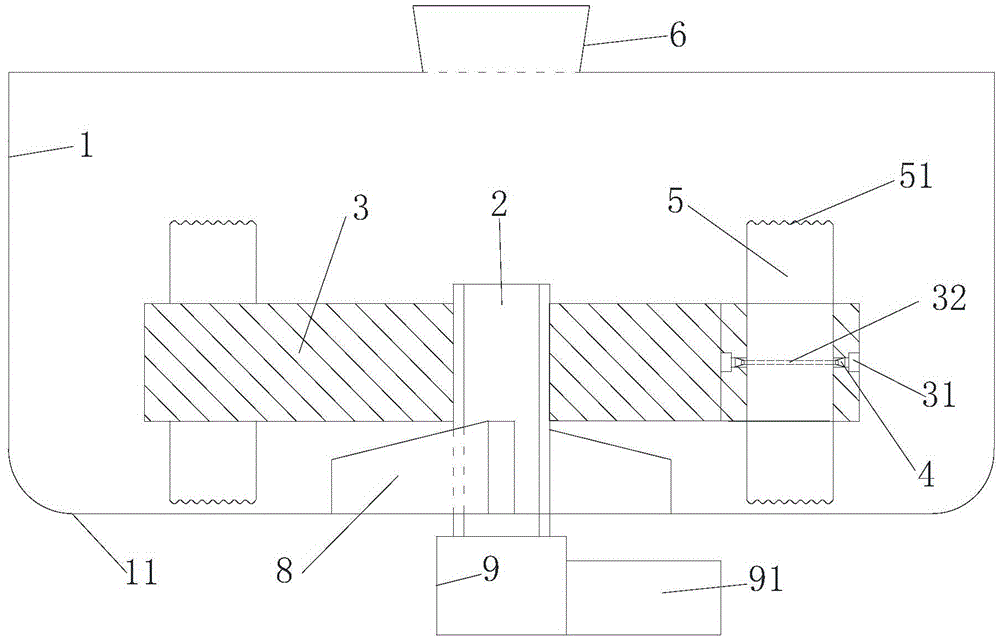

[0020] Such as figure 1 and figure 2 As shown, the "mixing mixer" of the present invention includes a box body 1, a main drive shaft 2 is arranged at the center of the box body 1, the lower section of the main drive shaft 2 is connected with a reducer 9, and the reducer 9 is connected with a motor 91; the box body 1 is provided with a feed inlet 6, and the bottom surface of the box body 1 is provided with a discharge port 7; between the bottom surface of the box body 1 and the side wall is a box body chamfer 11; The support arm 3, the two support arms 3 are right-angled and symmetrically distributed with respect to the center of the main transmission shaft 2, the other end of the support arm 3 is fixedly installed with two self-lubricating bearings 31, and the support shaft 32 is connected between the two self-lubricating bearings 31, The support shaft 32 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com