Forming system based on low-melting-point alloy semi-solid melt

A semi-solid, low-melting point technology, applied in the direction of feeding molten metal into molds, metal processing equipment, manufacturing tools, etc., can solve the problem of low alloy utilization, semi-solid alloy forming ability is not as good as lead forming ability, and preparation equipment Not easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further explained in conjunction with the accompanying drawings.

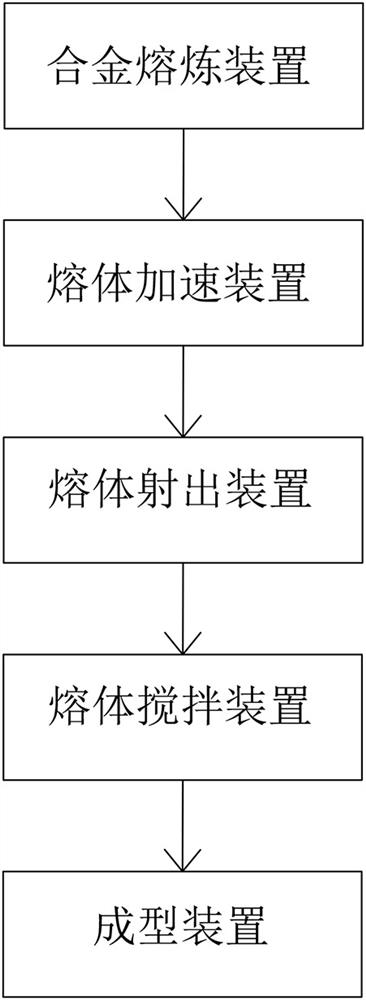

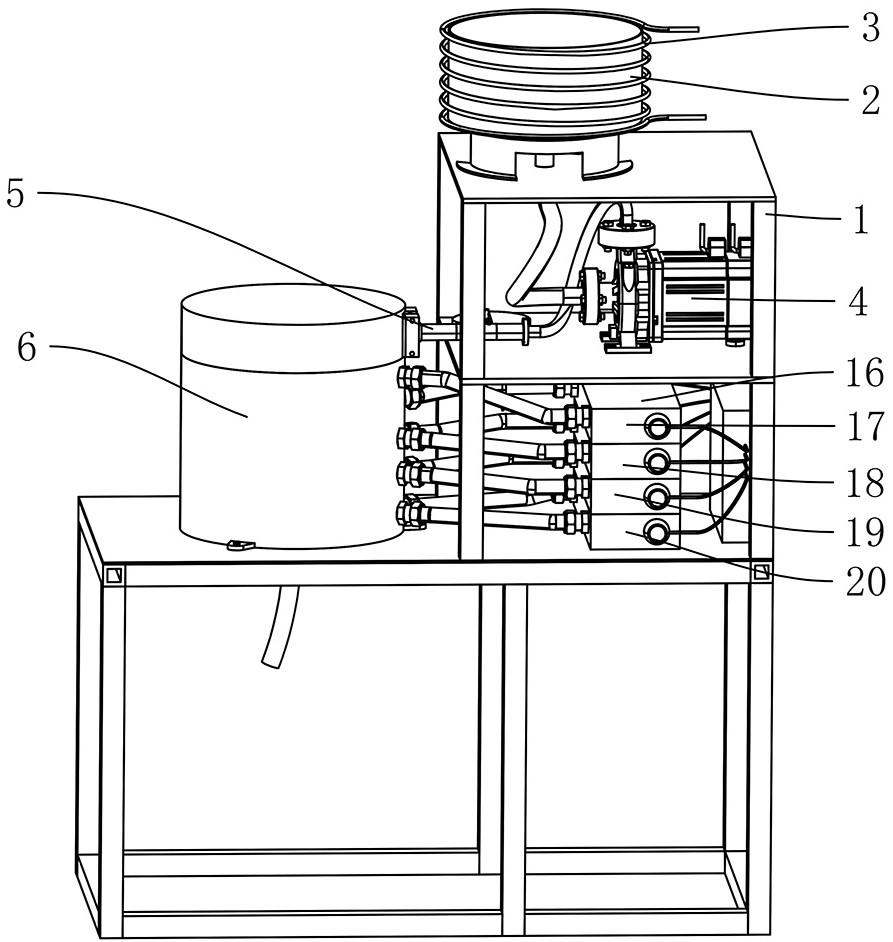

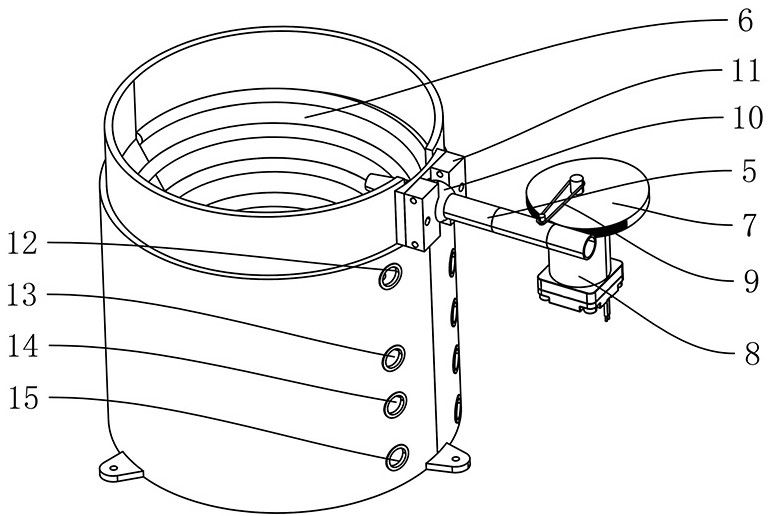

[0025] see Figure 1 to Figure 6 The shown forming system based on low-melting point alloy semi-solid melt includes a preparation device and a forming device, the preparation device includes a frame 1, including a frame 1, and the frame 1 is provided with an alloy melting device, a melt An acceleration device, a melt injection device, and a melt stirring device, the alloy melting device includes a crucible 2 and a heating element 3, the crucible 2 is used to place an alloy, and the heating element 3 heats the crucible 2 so that The alloy in the crucible 2 is smelted to form a semi-solid melt, the crucible 2 is set on the frame 1 through the mounting frame, the heating element 3 is an induction coil, and the induction coil is wound around the outer periphery of the crucible 2. The induction coil is fed with an alternating intermediate frequency current, and the strength of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com