A kind of edge roller crusher

A crusher and edge-roller technology, applied in the field of crushing devices, can solve problems such as difficult feeding of raw materials, and achieve the effects of easy feeding, good adaptability, and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

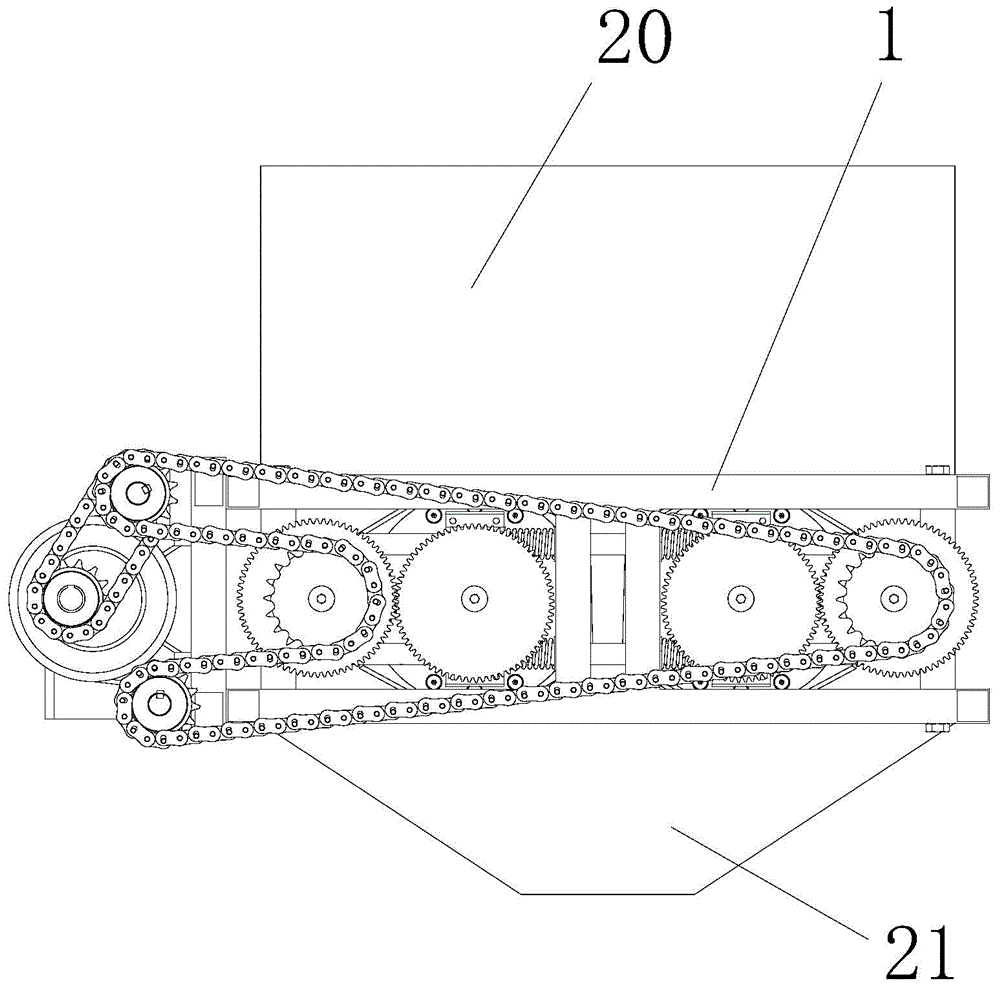

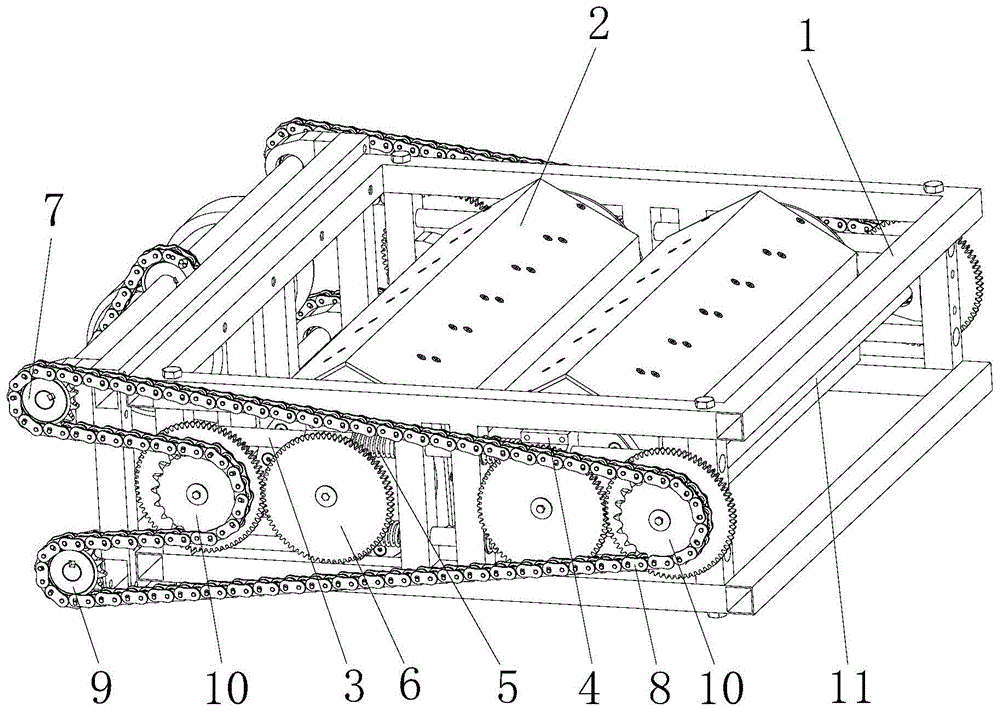

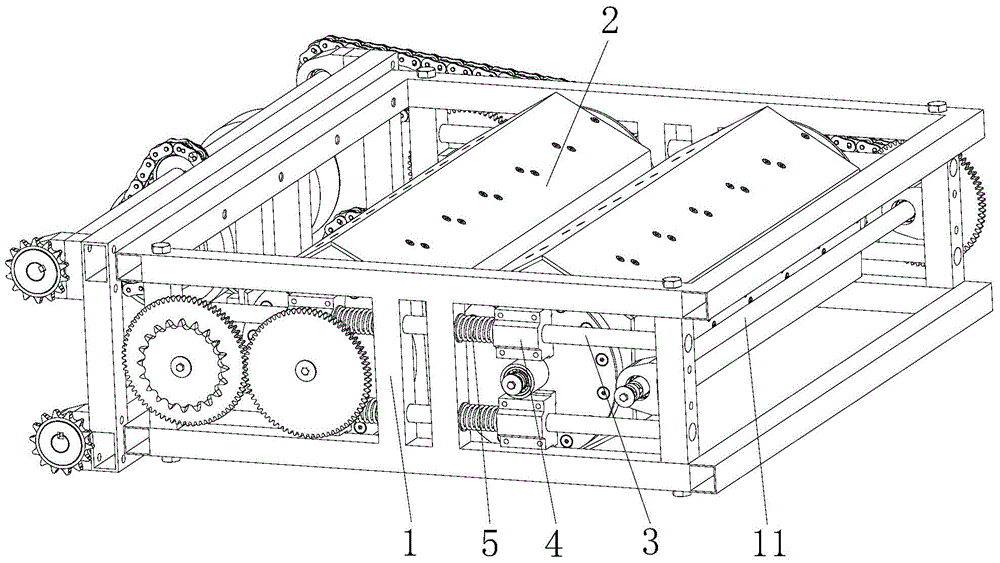

[0026] An edge-roll crusher includes a frame 1, two crushing edge rollers 2 that turn in opposite directions, and a power system that drives the two crushing edge rollers 2 to move simultaneously. The two crushing edge rollers 2 are respectively arranged on the frame 1.

[0027] The four end faces of the two crushing edge rollers 2 corresponding to the frame 1 are provided with a distance maintaining mechanism to keep the size of the crushing gap consistent throughout. The spring 5, the eccentric gear 6, the guide rod 3 are arranged along the arrangement direction of the two crushing edge rollers 2, the guide block 4 cooperates with the guide rod 3, the guide block 4 is fixed on the end face of the crushing edge roller 2, the shaft hole of the eccentric gear 6 is connected with the crushing The edge rollers 2 are connected at the axis positions, and the eccentric gear 6 is connected with the power system. Preferably, there are two guide rods 3 of the distance maintaining mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com