Storage system of automobile side wall clamp and automobile side wall welding production line

A storage system, a technology on the side of the automobile, applied in the processing field of the side wall of the automobile, can solve the problem of high storage cost of the fixture of the side wall of the automobile, and achieve the effect of reducing the storage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core of the present invention is to provide a storage system for the side wall clip of the automobile, which can reduce the storage cost of the side wall clip of the automobile. Another core of the present invention is to provide a welding production line for automobile side panels.

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

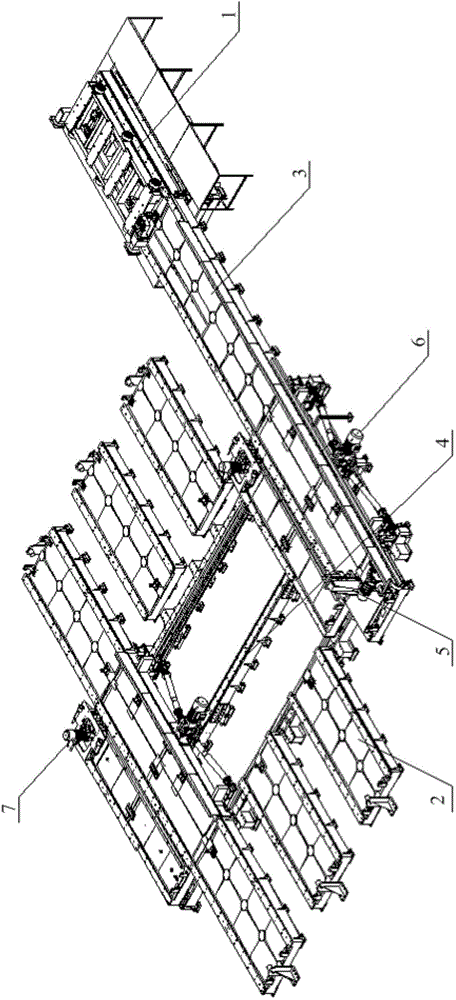

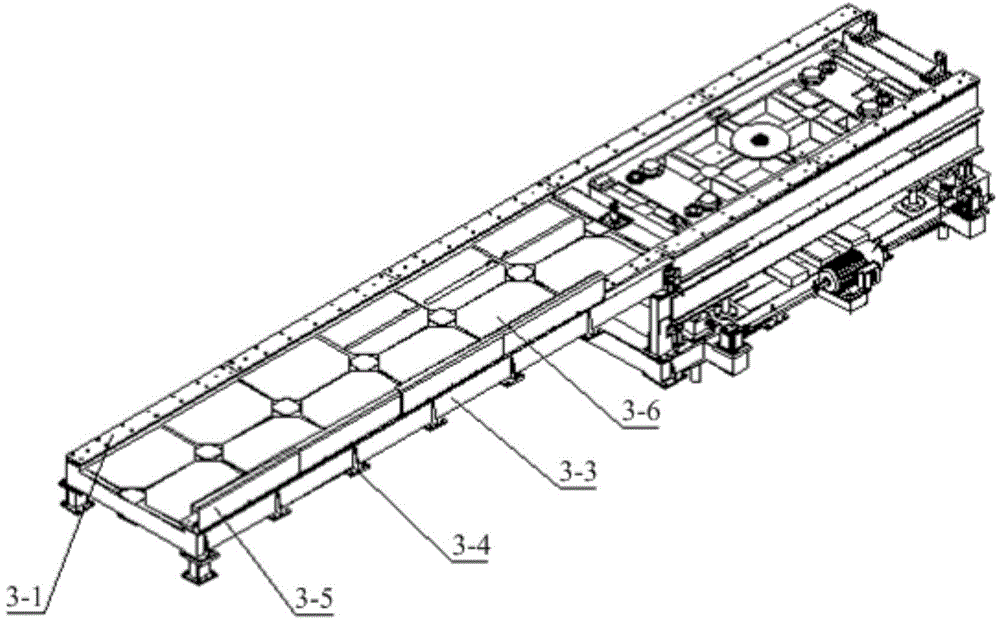

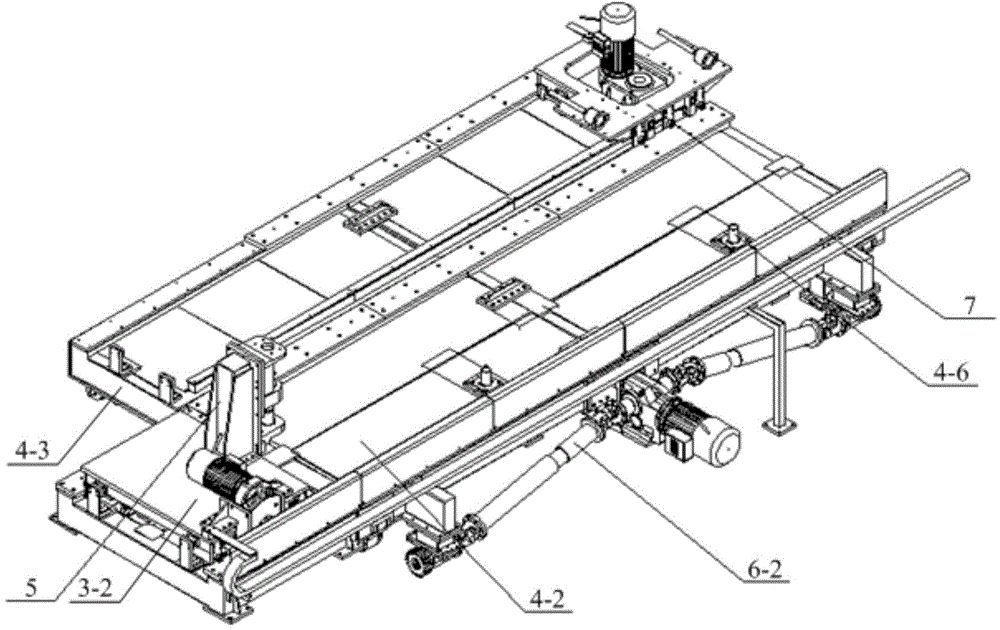

[0030] Such as Figure 1-5 As shown, the embodiment of the present invention provides a storage system for automobile side wall clamps, the storage system is used to transport the automobile side wall clamps from the position where the welding device 1 is located to the storage station of the automobile side wall clamps, which includes storage Apparatus 2 and conveyor line, wherein:

[0031] The storage device 2 is used to store the automobile side wall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap