Oscillating bar bearing structure of arc trimmer

A technology of arc dresser and support structure, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, metal processing equipment, etc., and can solve the problems of high manufacturing cost, deviation of diamond pen movement trajectory, and high processing accuracy requirements. To achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

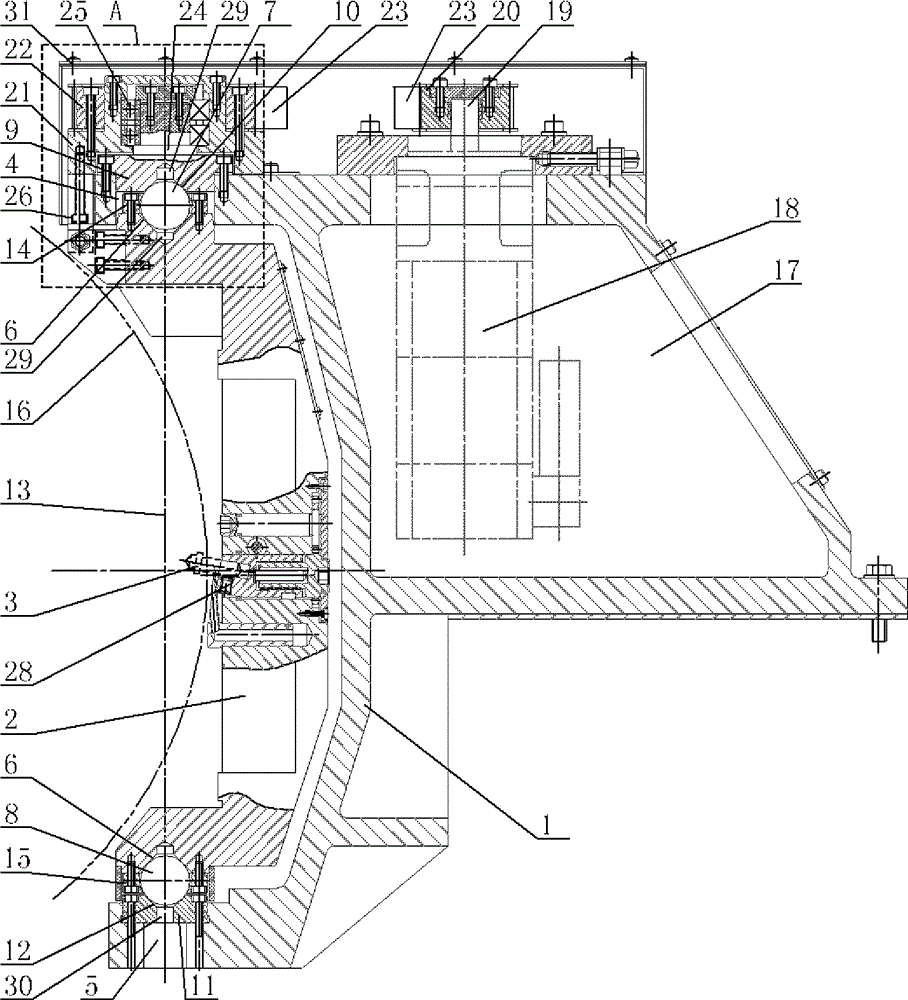

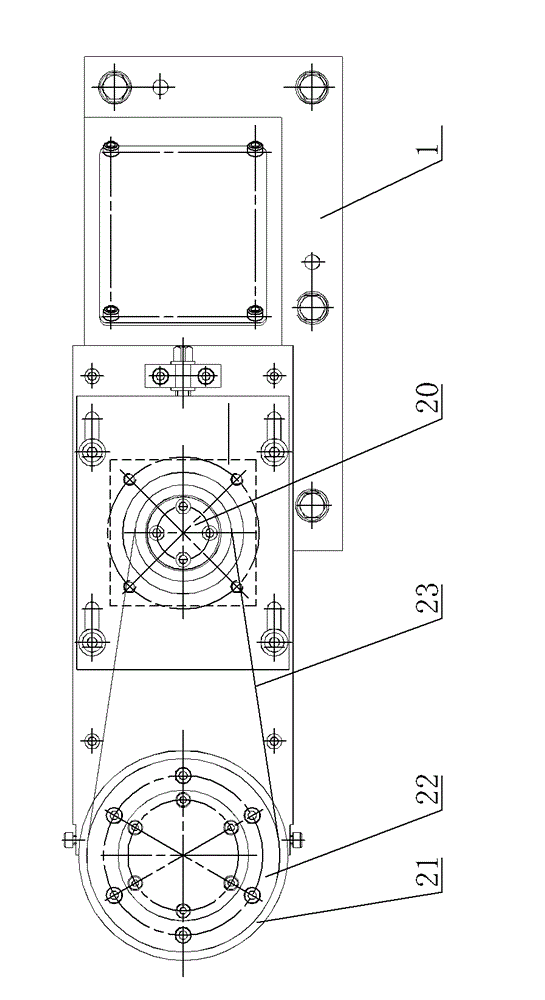

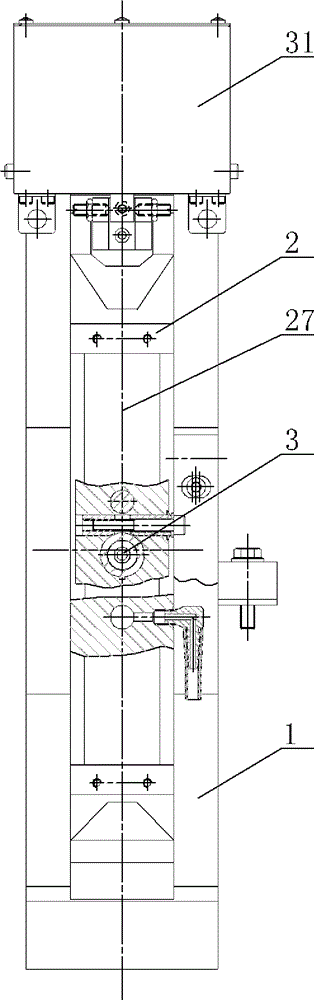

[0018] A swing rod support structure of a circular arc trimmer, see Figure 1 ~ Figure 4 : It includes a dresser base 1, a swing rod 2, and a diamond pen 3. The middle position of the swing rod 2 is arranged with a diamond pen 3. The upper end and the lower end of the swing rod 2 are respectively located in the corresponding upper end installation cavity of the dresser base 1. 4. The cavity 5 is installed at the lower end, and the protruding positions of the upper end and the lower end of the pendulum 2 are respectively provided with a conical frustum hole 6 with an inner concave end, and a steel ball structure is arranged in the conical frustum hole 6, and the steel ball structure specifically includes the upper end steel ball 7. The steel ball 8 at the lower end, the outer ring part of the upper gland 9 is fastened to the upper wall of the upper installation cavity 4 of the trimmer base 1, and the lower center of the upper gland 9 is provided with a concave conical upper hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com