Adjustable Rod Type Oxygen Lance Quick Changer

A technology of a changer and an oxygen lance, applied in the direction of manufacturing converters, etc., can solve the problems of complicated operation, accidental personnel, screwing the nut to the bottom, etc., achieving the effect of easy control of verticality, saving man-hours and manpower, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

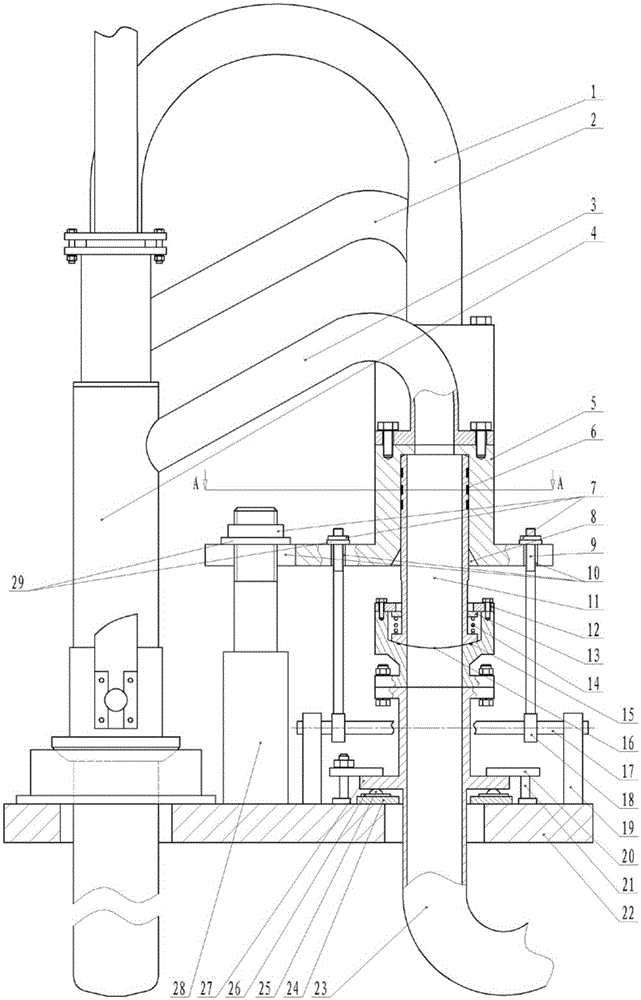

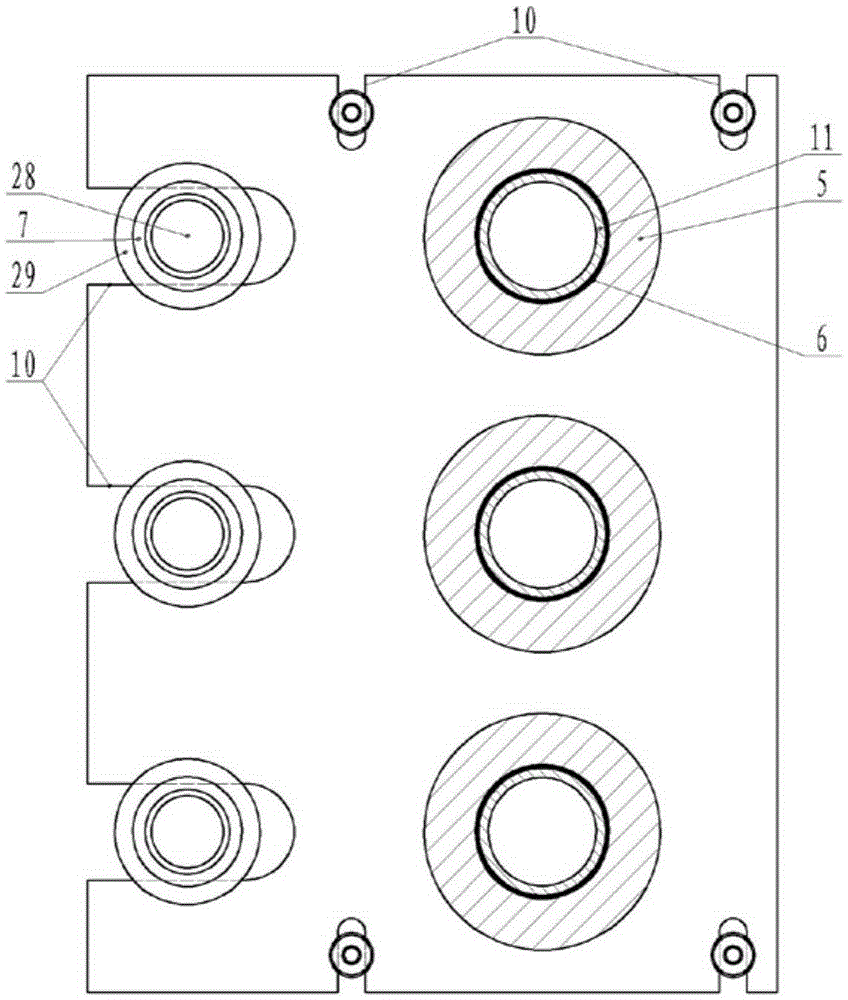

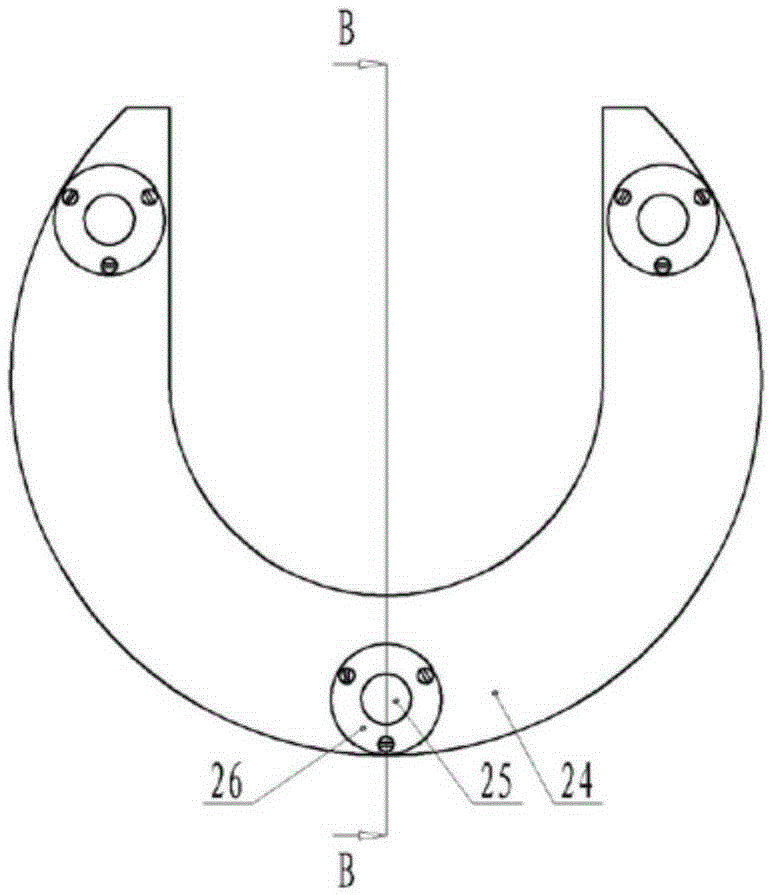

[0016] The self-aligning rod type oxygen lance quick changer includes the trolley platform 22 of the oxygen lance. The trolley platform is equipped with the oxygen lance 4, the fixing device of the oxygen lance, and the positioning device of the oxygen lance. The function of the positioning device is in the process of assembling the oxygen lance A device specially used for positioning the oxygen lance, the function of the fixing device is to fix the position of the oxygen lance after the oxygen lance is positioned;

[0017] The fixing device has a connecting plate 5, a fixed rod 28 and a movable rod 9, wherein the lower end of the fixed rod is welded and fixedly connected with the upper surface of the trolley platform, and the lower end of the movable rod is provided with a welded shaft sleeve 18, and the horizontal shaft sleeve is equipped with a movable connection. Shaft 17, the two ends of the horizontal shaft are respectively provided with shaft seats 19, and the two shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com