Timely cooling device for prebaked green anode block

A prebaked anode and cooling device technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as product quality impact, shoulder cracks, etc., to ensure quality, spray uniformity, ensure cooling time and cooling timeliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

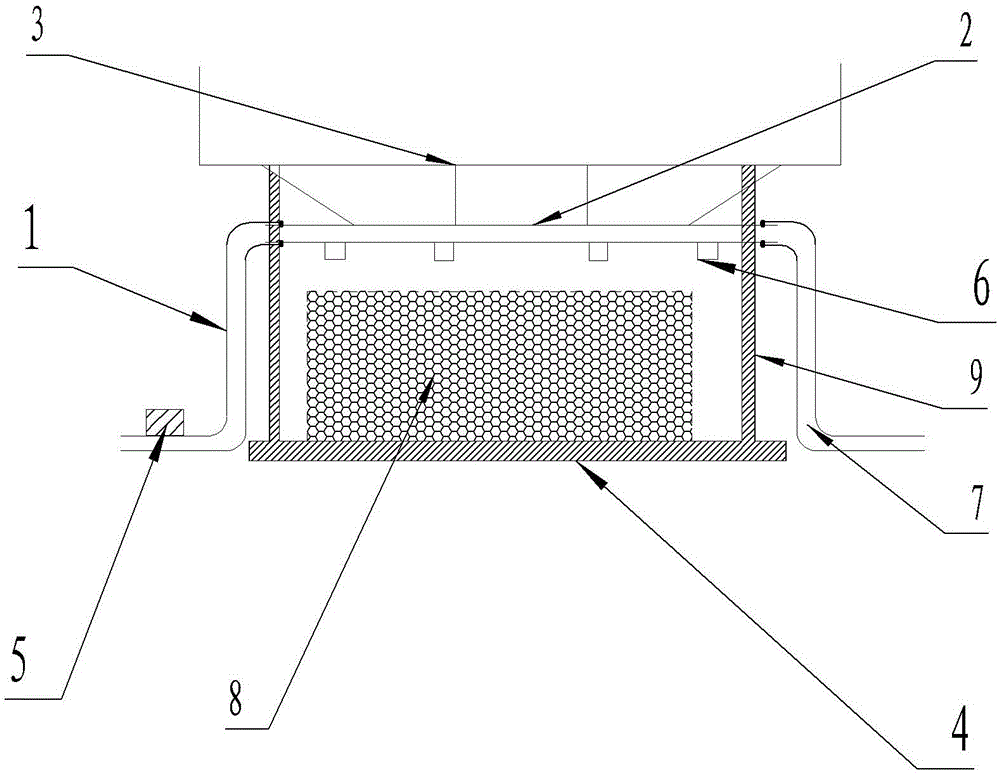

[0016] Such as figure 1 As shown, a timely cooling device for prebaked anode raw blocks includes a flexible water inlet conduit 1, a flexible water outlet conduit 7, a steel pipe 2, an electronic valve 5 and a bottom tray 4, and the bottom tray 4 is respectively provided with a bottom tray 4 vertical support rods 9, the top of the support rods 9 is equipped with a fixed bracket 3, so that the fixed bracket 3 is parallel to the bottom tray 4, and the fixed bracket 3 is horizontally and parallelly fixedly connected to the steel pipe 2, and the bottom tray 4 is placed The anode raw block 8 formed by vibration, one end of the water inlet flexible conduit 1 is sleeved on the cooling water pipe, the other end is sleeved on the steel pipe 2, the other end of the steel pipe 2 is sleeved on the water outlet flexible conduit 7, and the other end of the water outlet flexible conduit 7 is connected For the pool, the steel pipe 2 is provided with three openings on the side facing the botto...

Embodiment 2

[0018] Such as figure 1 As shown, a timely cooling device for prebaked anode raw blocks includes a flexible water inlet conduit 1, a flexible water outlet conduit 7, a steel pipe 2, an electronic valve 5 and a bottom tray 4, and the bottom tray 4 is respectively provided with a bottom tray 4 vertical support rods 9, the top of the support rods 9 is equipped with a fixed bracket 3, so that the fixed bracket 3 is parallel to the bottom tray 4, and the fixed bracket 3 is horizontally and parallelly fixedly connected to the steel pipe 2, and the bottom tray 4 is placed The anode raw block 8 formed by vibration, one end of the water inlet flexible conduit 1 is sleeved on the cooling water pipe, the other end is sleeved on the steel pipe 2, the other end of the steel pipe 2 is sleeved on the water outlet flexible conduit 7, and the other end of the water outlet flexible conduit 7 is connected In the pool, the steel pipe 2 is provided with 5 openings on the side facing the bottom tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com