A stainless steel sink with a water filter

A stainless steel filter technology, applied in water supply equipment, household cleaning equipment, indoor sanitary pipeline installations, etc., can solve the problems of waste of water resources, single function, waste of stainless steel plates, etc., to improve space utilization and save kitchen space , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

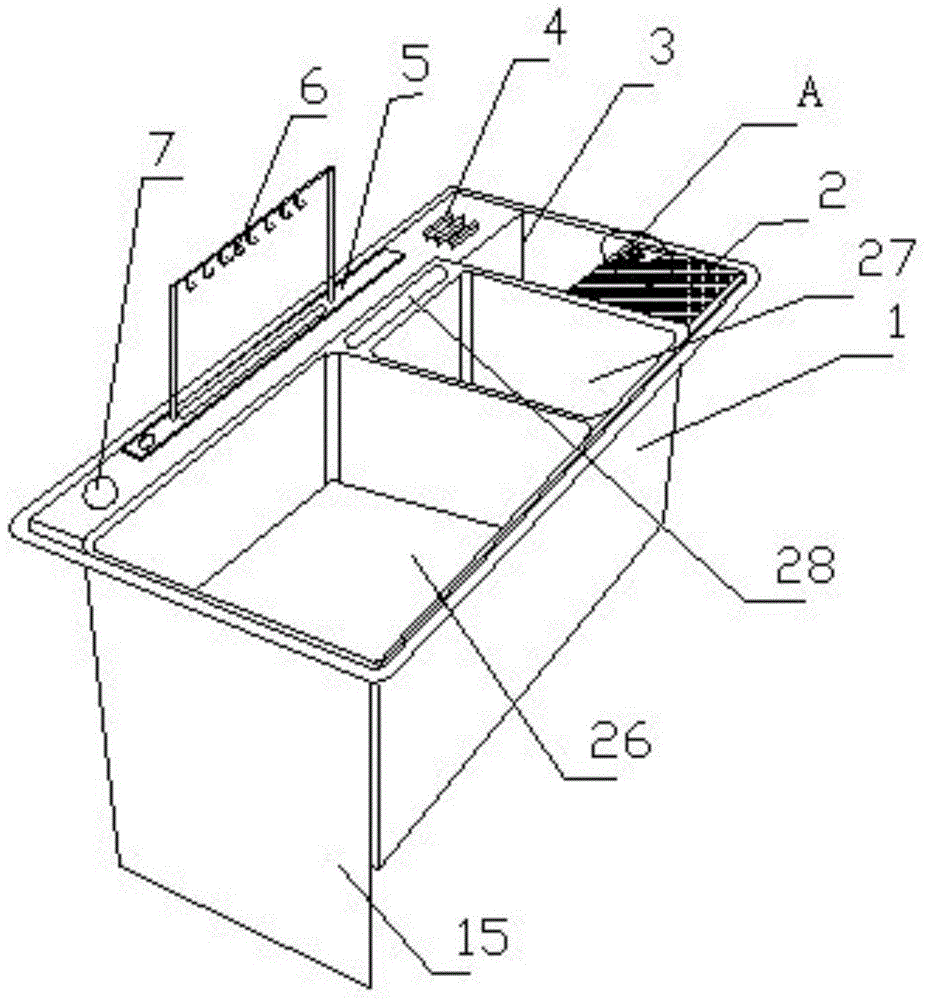

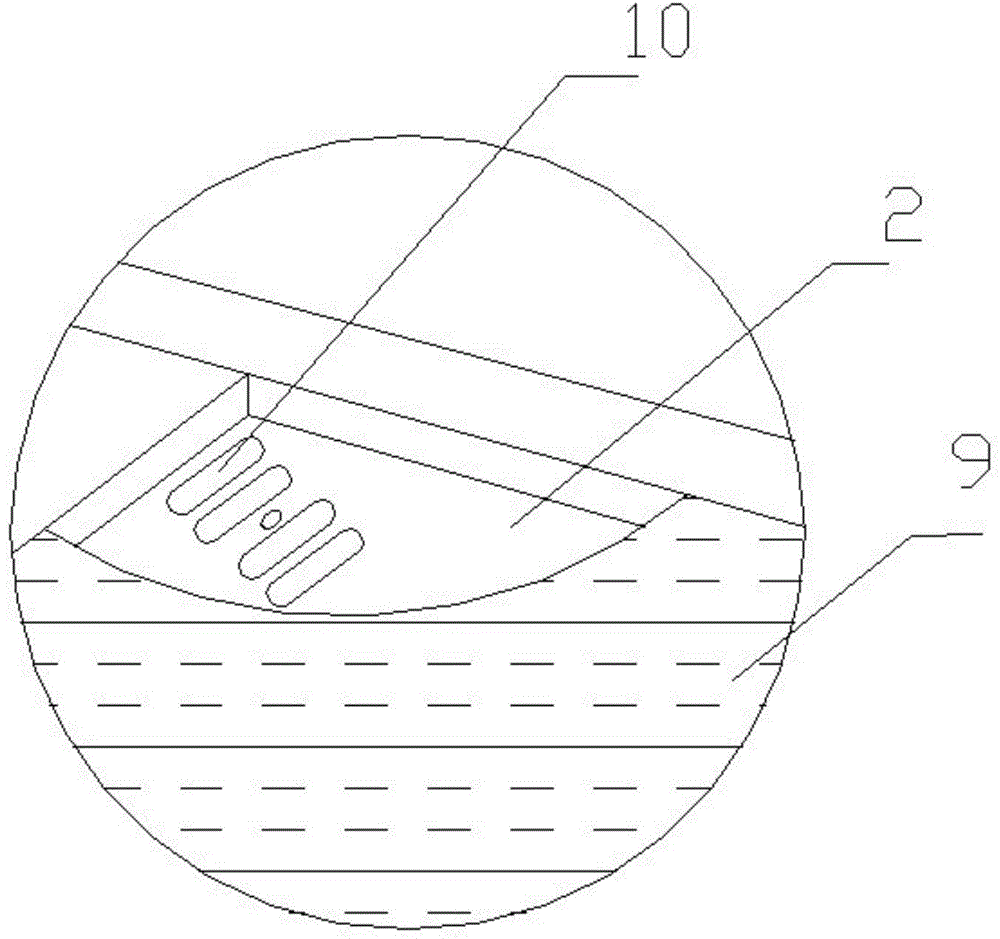

[0062] The present embodiment comprises the tank body 1 that is made of the first tank body 26 and the second tank body 27, and the right side of the second tank body 27 is provided with the chopping board tank 2, the garbage tank 3 and the soap placement rack 4, in the first tank body The rear side of the body 26 and the second tank body 27 is provided with a kitchen utensil table 5, the kitchen utensil table 5 is provided with a kitchen utensil rack 6, and the kitchen utensil table 5 is provided with a drip tank, the drip tank is located directly below the kitchen utensil rack 6, and along the kitchen utensil rack Extending, a detergent tank 7 is arranged on the left side of the kitchen table 5, and a water filter device is installed on the first tank body 26 and the second tank body 27 .

[0063] The water filtering device is a filter plate 30, and the filter plate 30 is a rectangular plate made of stainless steel, and a plurality of water filtering holes are uniformly arran...

Embodiment 2

[0075] The present embodiment comprises the tank body 1 that is made of the first tank body 26 and the second tank body 27, and the right side of the second tank body 27 is provided with the chopping board tank 2, the garbage tank 3 and the soap placement rack 4, in the first tank body The rear side of the body 26 and the second tank body 27 is provided with a kitchen utensil table 5, the kitchen utensil table 5 is provided with a kitchen utensil rack 6, and the kitchen utensil table 5 is provided with a drip tank, the drip tank is located directly below the kitchen utensil rack 6, and along the kitchen utensil rack Extending, a detergent tank 7 is arranged on the left side of the kitchen table 5, and a water filter device is installed on the first tank body 26 and the second tank body 27 .

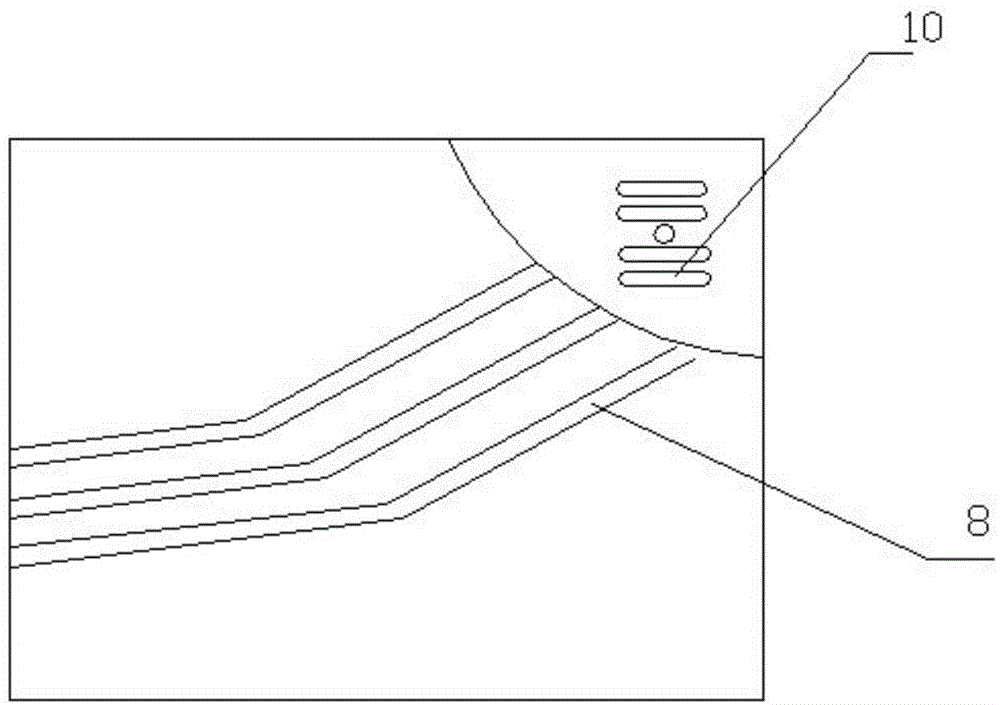

[0076] The filter water tank 29 is a tank body made of stainless steel, and a plurality of water filter holes are evenly arranged at the bottom of the tank body.

[0077] A cutter groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com